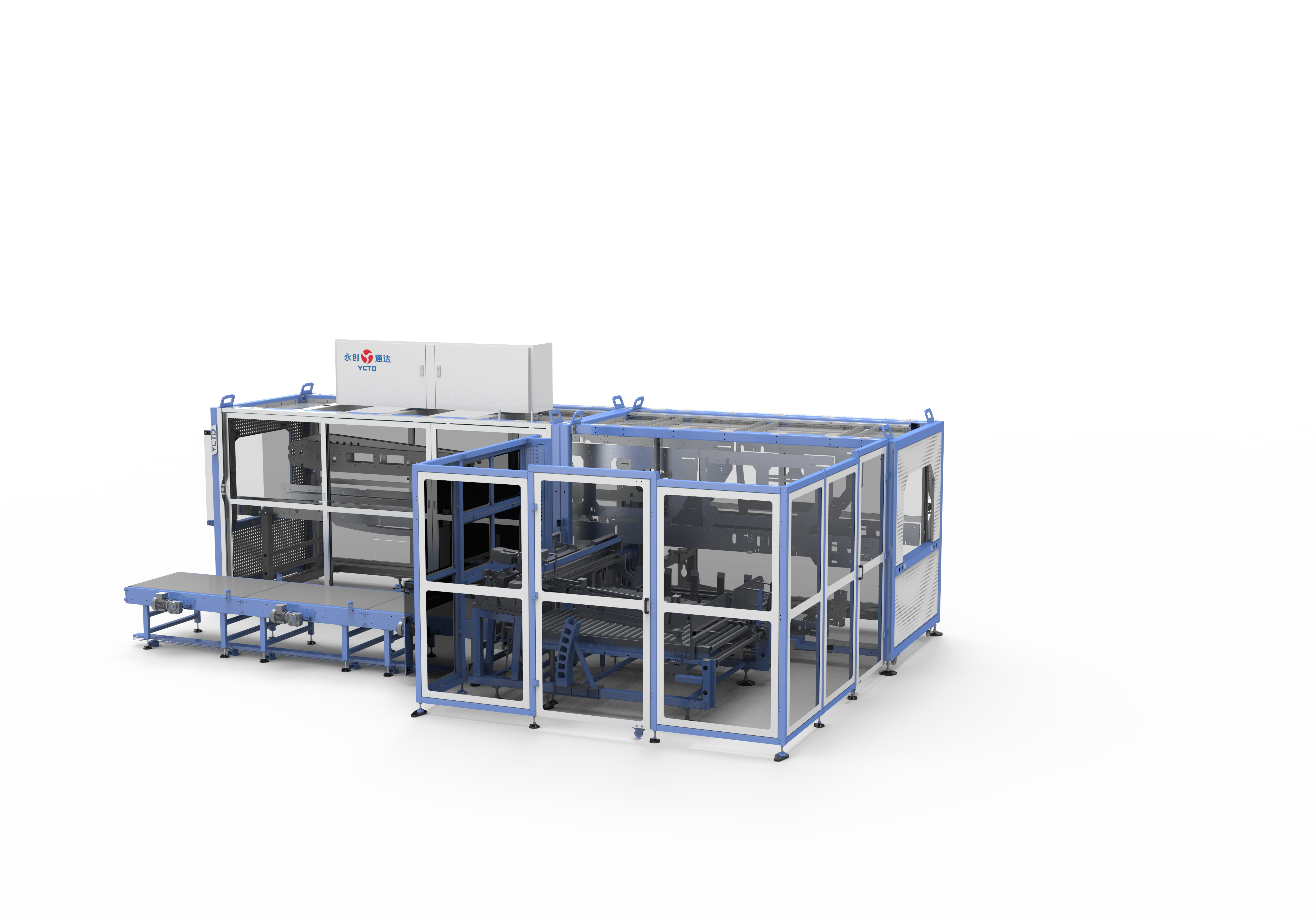

cartoner packaging machine

A cartoner packaging machine is an advanced automated system designed to efficiently package products into cartons or boxes. This versatile equipment streamlines the packaging process by folding, filling, and sealing cartons with precision and consistency. The machine incorporates multiple stations that handle different aspects of the packaging process, from carton erection to product insertion and final sealing. Modern cartoner machines feature sophisticated control systems with touchscreen interfaces, allowing operators to easily adjust settings and monitor performance. They can handle various carton sizes and styles, making them suitable for diverse industries including pharmaceuticals, food and beverage, cosmetics, and consumer goods. The machine's operation typically begins with the carton magazine, where flat carton blanks are stored and systematically fed into the forming section. The forming section shapes the carton, while the product loading station precisely inserts items using mechanical or robotic systems. Advanced models include quality control features such as barcode verification, missing product detection, and seal integrity checks. These machines can achieve impressive production speeds, typically ranging from 60 to 300 cartons per minute, depending on the model and application. They are built with durability in mind, featuring stainless steel construction and toolless changeover capabilities for enhanced operational efficiency.