yctd packaging machinery

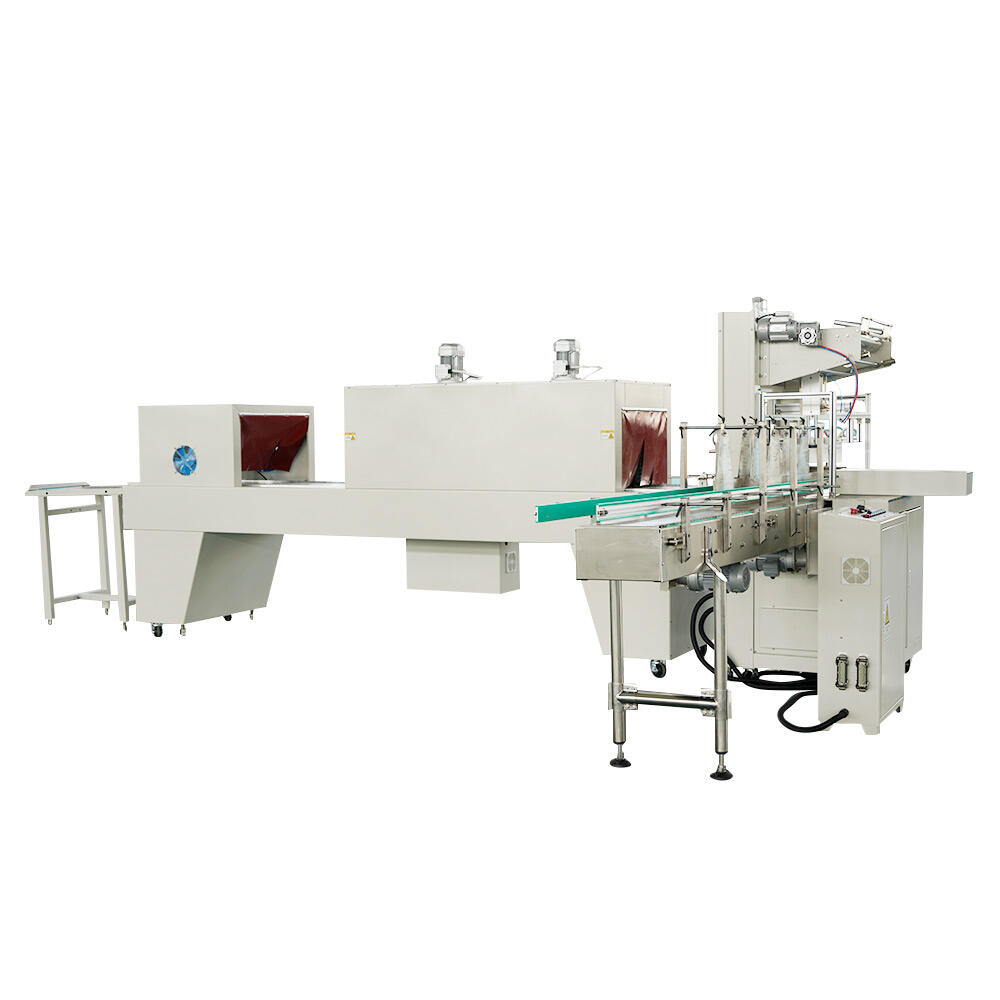

YCTD packaging machinery represents a comprehensive solution for modern industrial packaging needs, integrating advanced automation technology with precision engineering. This versatile system encompasses multiple packaging functions, including product sorting, filling, sealing, and labeling capabilities. The machinery utilizes state-of-the-art servo motors and intelligent control systems to ensure accurate and consistent packaging operations. With its modular design, the system can be customized to accommodate various product sizes and packaging materials, making it suitable for diverse industries such as food and beverage, pharmaceuticals, and consumer goods. The machinery features an intuitive touch-screen interface that enables easy operation and quick parameter adjustments. Its robust construction, incorporating stainless steel components, ensures durability and compliance with hygiene standards. The system's high-speed processing capability can handle up to 200 packages per minute, while maintaining precise quality control through integrated vision systems. Advanced safety features, including emergency stop functions and protective guards, ensure operator safety while maintaining optimal production efficiency. The machinery also includes real-time monitoring capabilities, allowing for preventive maintenance and minimizing downtime.