Unlocking Efficient Packaging Strategies for Modern Businesses

Effective packaging solutions play a critical role in optimizing logistics and reducing expenses across supply chains. One technology that has gained traction among manufacturers and distributors is the shrink film machine. By combining speed, protection, and material savings, a shrink film machine offers an innovative approach to securing products for transit. Understanding the mechanics, cost benefits, and operational considerations of this equipment can help businesses make informed decisions and achieve significant savings over time.

Operational Principles and Workflow Integration

Film Compatibility and Application Techniques

Selecting the appropriate shrink film material is essential for achieving uniform coverage and strong seals. A shrink film machine works by applying heat to a thermoplastic film, causing it to conform tightly around the product. Different materials such as polyolefin, PVC, and polyethylene have distinct shrink ratios and strength properties, enabling customization for various packaging needs. Ensuring proper film compatibility enhances seal integrity and minimizes waste, which directly influences cost efficiency.

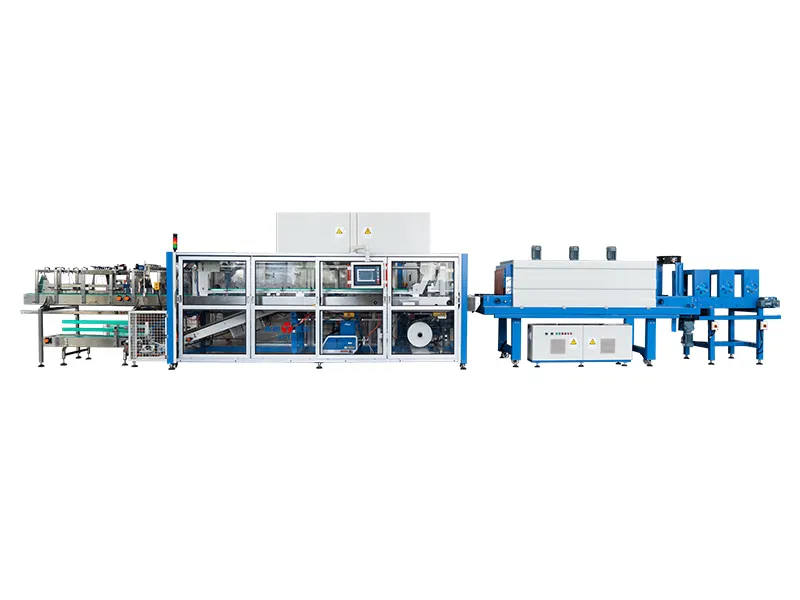

Automation Levels and Throughput Optimization

Shrink film machines are available in manual, semi-automatic, and fully automatic configurations. Automating the process increases output capacity and consistency, while reducing labor requirements. Integrating a shrink film machine into existing production lines involves aligning conveyor speeds, sensor calibration, and operator training. Smooth workflow integration reduces downtime and maximizes packaging productivity, contributing to lower overall operational costs.

Cost Savings through Material and Labor Efficiency

Reducing Film Consumption and Waste

Advanced shrink film machines use precise temperature controls and adjustable sealing jaws to optimize film usage. By calibrating parameters such as dwell time and air flow, machines can achieve tighter film wraps with thinner gauge materials. This reduces film consumption without compromising protection. Lower material usage translates directly into cost savings on raw materials and waste disposal.

Minimizing Labor Expenses and Manual Intervention

Manual packaging often demands significant labor hours for film placement, sealing, and trimming. A shrink film machine automates these tasks, allowing operators to oversee multiple machines simultaneously. This labor scaling effect lowers per-unit labor costs and reallocates workforce to higher-value tasks. Reduced reliance on manual labor also mitigates ergonomic risks and error rates associated with repetitive motions.

Product Protection and Branding Advantages

Enhancing Shipment Durability and Product Safety

Shrink film wraps create a snug barrier around products, protecting against moisture, dust, and tampering. The tight seal provided by a shrink film machine ensures that packages arrive in pristine condition. Consistent film application prevents loose corners and punctures, reducing damage-related returns and associated costs.

Customizable Presentation and Brand Visibility

Shrink film machines allow for clear or printed films that showcase product labels and branding elements. Transparent films highlight product features, while printed shrink films carry logos and marketing messages. Consistent wrap quality enhances shelf appeal and consumer confidence. Efficient branding capabilities help businesses differentiate their offerings without significant increases in packaging expenses.

Scalability and Return on Investment Analysis

Calculating Payback Period and Total Cost of Ownership

Investing in a shrink film machine requires analysis of upfront costs, maintenance expenses, and expected savings. Factors such as film price differentials, labor reductions, and damage rate improvements contribute to ROI calculations. A detailed payback period assessment compares initial capital outlay to monthly savings, helping decision-makers justify the investment.

Scaling Operations for Seasonal and Demand Fluctuations

Businesses with variable production volumes benefit from modular shrink film machine configurations. Scalable systems can be expanded with additional sealing tunnels, conveyor extensions, or robotic loaders to accommodate peak seasons. Flexible scalability ensures capital investments align with growth trajectories while avoiding underutilized capacity.

Environmental and Compliance Considerations

Eco-Friendly Film Options and Waste Reduction

Eco-conscious companies can choose shrink films manufactured from recycled resins or biodegradable polymers. A shrink film machine designed for lower temperature operation facilitates the use of sensitive eco-films. Reduced film thickness and precise sealing minimize plastic consumption and waste, supporting sustainability goals.

Adherence to Safety and Regulatory Standards

Operating a shrink film machine entails compliance with local safety regulations and workplace guidelines. Features such as built-in temperature sensors, emergency stop buttons, and protective guards enhance operator safety. Regular maintenance and calibration ensure equipment remains within specified operating parameters, preventing hazards and avoiding regulatory fines.

FAQ

What types of films are compatible with a shrink film machine?

Most shrink film machines support polyolefin, PVC, and polyethylene films. Each film type offers different shrink ratios and barrier properties to match specific packaging requirements.

How does a shrink film machine lower overall packaging costs?

By automating sealing and trimming, it reduces labor expenses, optimizes film usage through precise controls, and decreases product damage rates, leading to comprehensive cost savings.

Can a shrink film machine adapt to varying production volumes?

Yes, modular systems allow businesses to add sealing tunnels and conveyor extensions, enabling rapid scaling for seasonal peaks without large upfront investments.

Are there sustainable film options for environmentally conscious operations?

Recycled resin and biodegradable shrink films can be used at lower operating temperatures, helping companies reduce plastic waste and meet sustainability targets.