Transforming Product Packaging with Advanced Wrapping Technology

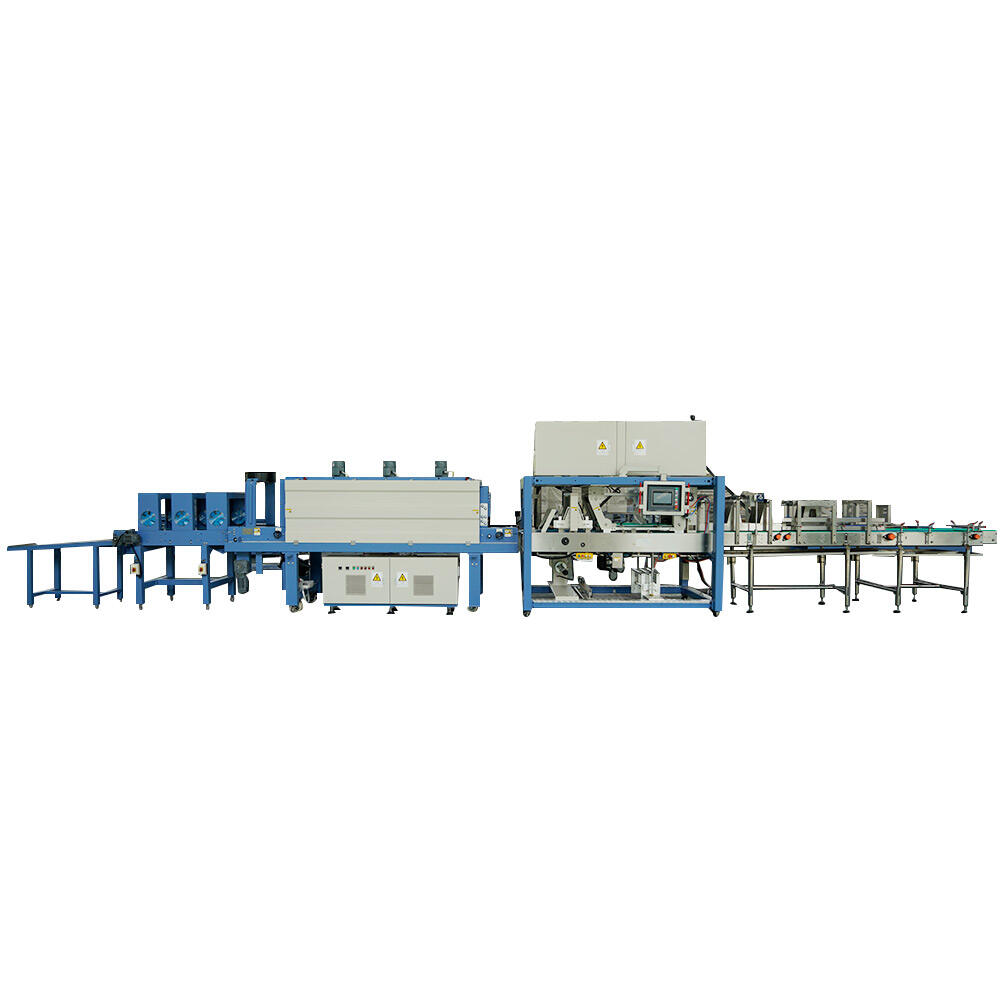

The modern retail landscape demands impeccable product presentation, and a shrink film wrapping machine stands at the forefront of this packaging revolution. These sophisticated systems have become indispensable in manufacturing and distribution facilities worldwide, offering a seamless solution for creating professional, tamper-evident packaging that catches consumers' attention. By implementing this technology, businesses can achieve consistent, high-quality presentation while streamlining their packaging operations.

From consumer goods to industrial products, the versatility of shrink film wrapping machines has revolutionized how companies protect and present their merchandise. The technology not only ensures product security but also delivers that crisp, professional finish that modern consumers have come to expect. As we delve deeper into this topic, we'll explore the numerous ways these machines can elevate your product presentation and boost your bottom line.

The Science Behind Shrink Film Packaging

Understanding the Shrink Film Process

At its core, a shrink film wrapping machine operates by encasing products in a specialized polymer film that contracts when exposed to controlled heat. This process begins with precise film measurement and cutting, followed by wrapping the product and applying heat through a tunnel or chamber. The molecular structure of the film responds to the heat by shrinking uniformly, creating a tight, crystal-clear wrap that conforms perfectly to the product's shape.

Modern shrink film wrapping machines utilize advanced temperature control systems and conveyor mechanisms to ensure consistent results. The heating process must be carefully calibrated to achieve optimal shrinkage without damaging the product or creating unsightly wrinkles in the film. This precision engineering results in packages that not only look professional but also provide superior protection.

Material Innovation and Selection

The evolution of shrink film materials has kept pace with technological advances in wrapping machinery. Today's films offer enhanced clarity, strength, and sustainability options. Polyolefin films have become increasingly popular due to their excellent optical properties and environmental benefits. These materials can be precisely controlled by a shrink film wrapping machine to create packages that enhance product visibility while maintaining structural integrity.

Different products require specific film characteristics, and modern machines can accommodate various film types and thicknesses. From heavy-duty industrial applications to delicate consumer goods, the right combination of film and machine settings ensures optimal results. The latest machines even incorporate smart sensors that automatically adjust parameters based on the product and film specifications.

Benefits for Brand Image and Marketing

Visual Appeal and Shelf Impact

A shrink film wrapping machine creates packaging that serves as a powerful marketing tool. The glossy, transparent finish achieved through professional shrink wrapping immediately elevates product perception. This enhanced presentation can significantly impact consumer purchasing decisions, as products with clean, professional packaging often command premium positioning in the retail environment.

The uniform appearance created by automated shrink wrapping helps establish brand consistency across product lines. When consumers encounter multiple products with the same high-quality presentation, it reinforces brand reliability and professionalism. This visual consistency becomes a crucial element in building brand recognition and trust.

Product Protection and Security

Beyond aesthetics, a shrink film wrapping machine provides robust protection against environmental factors and tampering. The tight seal created by the shrinking process prevents dust, moisture, and contaminants from reaching the product. This protection maintains product quality throughout the supply chain and extends shelf life.

Security features can be incorporated into the shrink film packaging process, such as tamper-evident bands or security perforation lines. These elements not only protect products but also instill consumer confidence in product authenticity and safety. Modern machines can apply these security features consistently and efficiently across large production runs.

Operational Efficiency and Cost Benefits

Streamlined Production Processes

Implementing a shrink film wrapping machine significantly improves packaging efficiency. These systems can process hundreds of products per hour, dramatically reducing labor costs and increasing throughput. The automated nature of the process eliminates human error and ensures consistent quality across all packages.

Modern machines feature quick changeover capabilities, allowing businesses to switch between different product sizes and configurations with minimal downtime. This flexibility enables efficient handling of various SKUs and seasonal production demands, maximizing equipment utilization and return on investment.

Cost Optimization and Waste Reduction

While the initial investment in a shrink film wrapping machine may seem substantial, the long-term cost benefits are significant. Automated systems optimize film usage, reducing material waste and associated costs. The precise control over film application and shrinkage ensures minimal material overlap and efficient use of resources.

Additionally, the durability of shrink-wrapped packages reduces damage during transportation and handling, lowering replacement costs and customer returns. The standardized packaging process also streamlines warehouse operations and reduces storage space requirements, contributing to overall operational cost savings.

Frequently Asked Questions

How does a shrink film wrapping machine handle different product sizes?

Modern shrink film wrapping machines are designed with adjustable settings and components that can accommodate various product dimensions. They typically feature quick-change parts and programmable controls that allow operators to switch between different product sizes efficiently. Many advanced models include automatic size detection and adjustment capabilities.

What maintenance is required for optimal machine performance?

Regular maintenance of a shrink film wrapping machine includes cleaning heating elements, checking and lubricating moving parts, calibrating temperature controls, and inspecting sealing mechanisms. Most manufacturers recommend daily cleaning procedures and scheduled preventive maintenance to ensure consistent performance and longevity.

Can environmentally friendly films be used with these machines?

Yes, modern shrink film wrapping machines are compatible with eco-friendly film options, including biodegradable and recycled materials. Many manufacturers now offer sustainable film solutions that maintain the same high-quality presentation while reducing environmental impact. The machines can be calibrated to work effectively with these alternative materials.