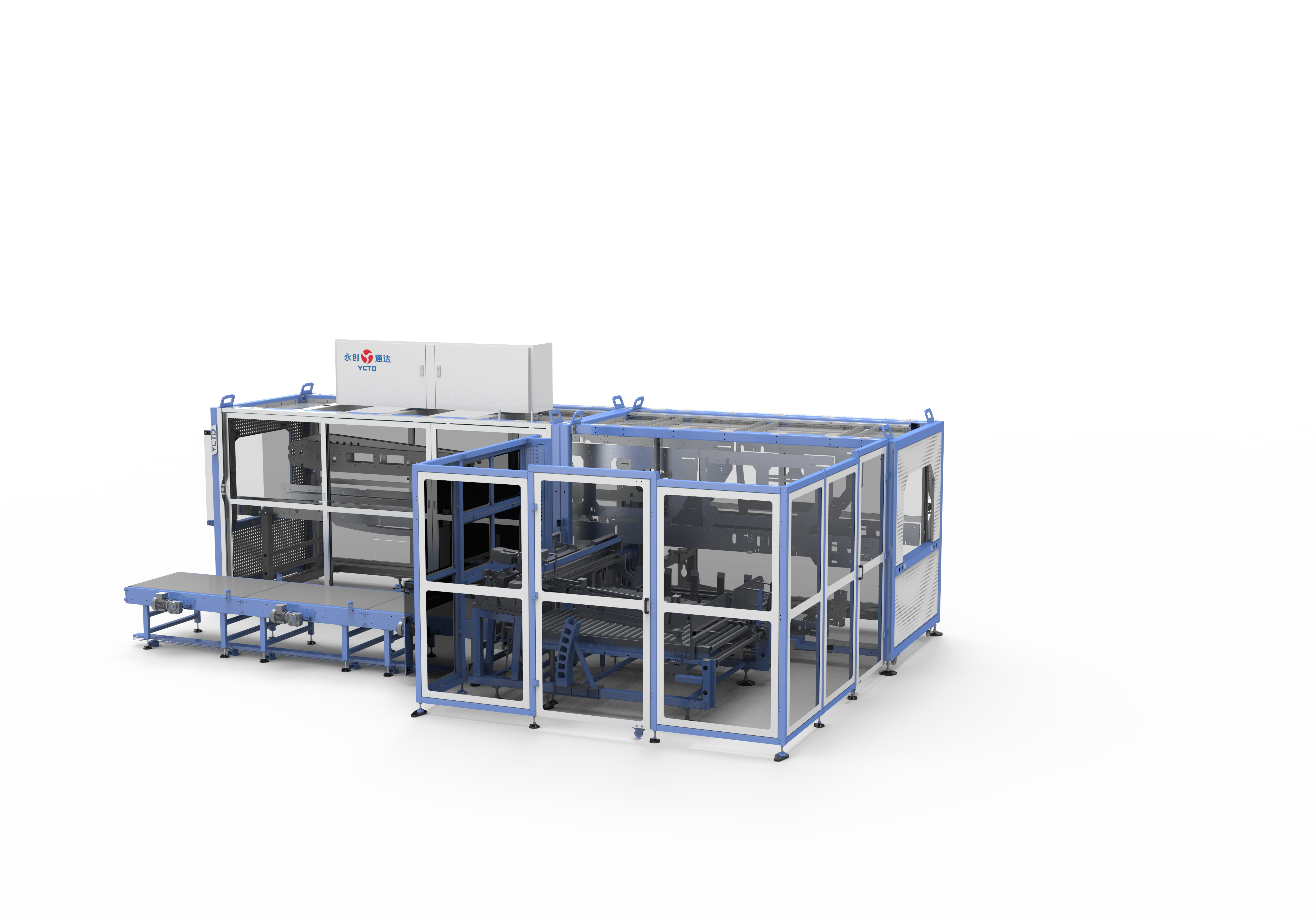

giá máy đóng gói thùng carton

Giá máy đóng thùng carton là một yếu tố đáng kể đối với các doanh nghiệp đang tìm kiếm việc tự động hóa trong hoạt động đóng gói. Những máy này, có sẵn ở nhiều mức giá khác nhau từ 15.000 đến 50.000 USD, cung cấp các giải pháp toàn diện cho nhu cầu đóng gói hiệu quả. Giá cả thay đổi tùy thuộc vào các yếu tố như mức độ tự động hóa, năng suất sản xuất và các tính năng công nghệ. Các mẫu cơ bản thường xử lý từ 10-15 thùng carton mỗi phút, trong khi các hệ thống cao cấp có thể xử lý tới 40-50 thùng mỗi phút. Phần lớn các máy hiện đại đều tích hợp hệ thống điều khiển PLC, giao diện màn hình cảm ứng và công nghệ động cơ servo, đảm bảo vận hành chính xác và yêu cầu bảo trì tối thiểu. Mức giá thường phản ánh các tính năng bổ sung như hệ thống cấp carton tự động, hệ thống keo nóng chảy và khả năng dựng thùng tự động. Các mẫu tầm trung, có giá từ 25.000 đến 35.000 USD, thường được trang bị hệ thống kiểm soát chất lượng tích hợp và khả năng chẩn đoán từ xa. Những máy này được thiết kế để phù hợp với nhiều kích cỡ và kiểu dáng carton khác nhau, phù hợp cho đa dạng ứng dụng trong các ngành công nghiệp như thực phẩm và đồ uống, dược phẩm và hàng tiêu dùng.