In today’s competitive beverage industry, packaging is more than just a final production step—it’s a vital factor in ensuring product integrity, improving efficiency, and building a strong brand presence. As beverage manufacturers scale production and distribution, investing in the right equipment becomes crucial. One of the most important tools in any modern beverage packaging line is the shrink wrapper machine.

Here’s why a shrink wrapper is not just useful—but essential—for beverage factories striving for excellence.

1. Shrink Wrapping for Superior Product Protection

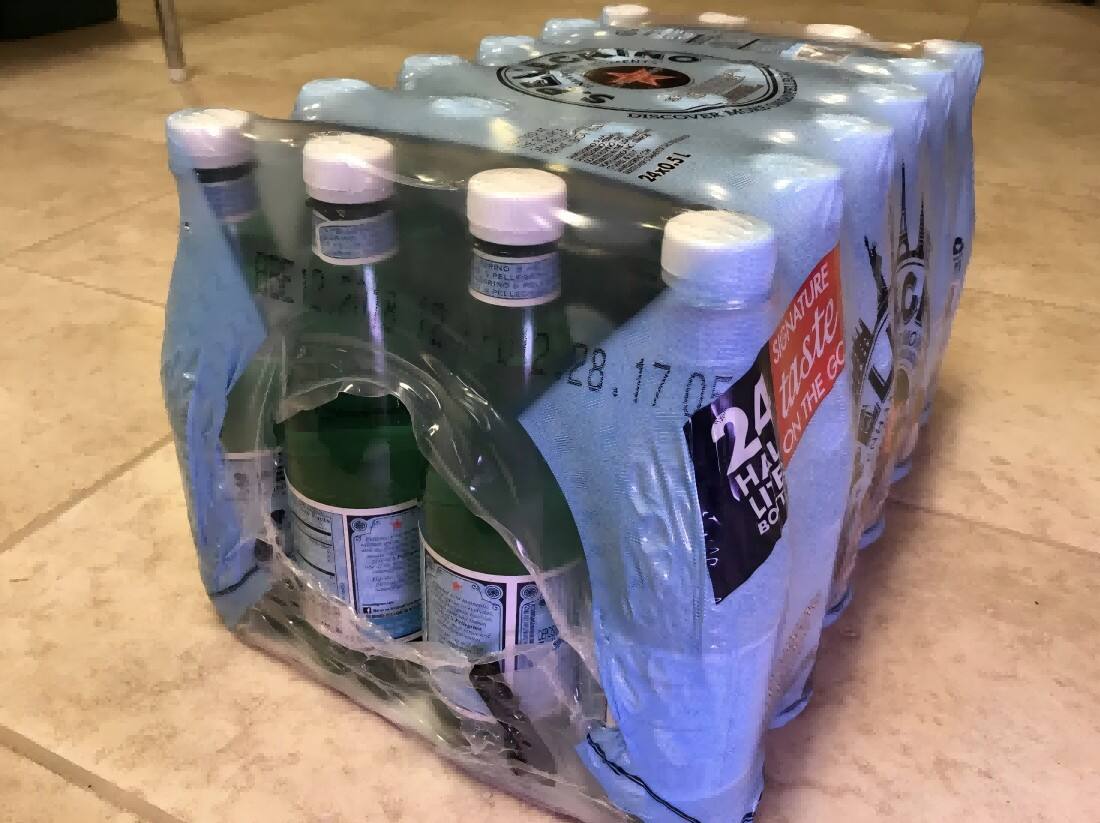

Shrink wrapping creates a secure, tamper-resistant seal around bottles or cans, providing a critical layer of protection. It shields beverages from moisture, dust, dirt, and handling damage. This is particularly important during storage, palletizing, and long-distance transportation, where product integrity can be easily compromised without proper packaging.

A tightly shrink-wrapped bundle ensures that every unit arrives at its destination in perfect condition, which directly impacts customer satisfaction and brand reputation.

2. High-Speed Shrink Wrapper Machines Improve Efficiency

Modern shrink wrapper machines are designed for high-speed production environments. They automate the wrapping process, significantly reducing manual labor and packaging time. Capable of processing dozens—or even hundreds—of beverage units per minute, these machines are essential for beverage factories looking to meet high output demands while maintaining consistent packaging quality.

This level of automation not only improves throughput but also reduces operational costs and the likelihood of human error.

3. Shrink Packaging Is Cost-Effective and Sustainable

Compared to traditional packaging methods like cardboard boxes or rigid containers, shrink packaging uses significantly less material. The result is lighter packages, reduced waste, and lower shipping costs. Additionally, many shrink wrap materials are now recyclable or made from eco-friendly polymers, helping companies meet their sustainability goals without compromising performance.

Reducing material consumption also aligns with growing environmental regulations and consumer expectations for greener packaging solutions.

4. Shrink Wrap Enhances Product Visibility and Shelf Appeal

Unlike opaque boxes, shrink wrap allows full visibility of the product. This is a powerful advantage in retail settings where clear, clean, and aligned packaging can catch the eye of consumers. A well-shrink-wrapped six-pack of colorful drinks is much more appealing on the shelf than a generic cardboard box.

Additionally, labels and branding remain fully visible, making it easier to promote seasonal or limited-edition beverage lines without redesigning external packaging.

5. Flexible Shrink Wrapping Machines Adapt to Product Variety

A key advantage of advanced shrink wrapper machines is their versatility. They can handle a variety of product configurations—single items, multi-packs, promotional bundles, and more. This flexibility is crucial for beverage factories that produce different SKUs or frequently change packaging formats based on market demand.

Whether you’re wrapping 330ml cans, 500ml bottles, or irregularly shaped containers, a high-quality shrink wrapping machine ensures seamless adaptability.

6.Shrink Wrap Systems Support Operational Scalability

As your beverage business grows, so does the complexity of your packaging needs. Shrink wrapper systems are scalable solutions that can evolve with your production line. Many machines are modular, allowing for future upgrades or integration with robotic palletizers, labelers, and conveyor systems.

By investing in a robust shrink wrapping solution, you prepare your facility not only for today’s demand but also for future expansion.

Conclusion: Why Beverage Plants Need Shrink Wrapper Machines

For beverage factories, packaging is a strategic asset. A shrink wrapper machine delivers speed, reliability, protection, and brand impact—all essential for thriving in a fast-moving market. From reducing costs to improving the look and security of your products, shrink wrapping is the smart choice for manufacturers at any scale.

At YCTD, we specialize in state-of-the-art shrink wrapper machines for beverage industry. Whether you’re launching a new product line or upgrading your current packaging process, our team can help you select a machine that maximizes efficiency and ROI.

Get in touch with YCTD today to discover the perfect shrink wrap solution for your beverage business.