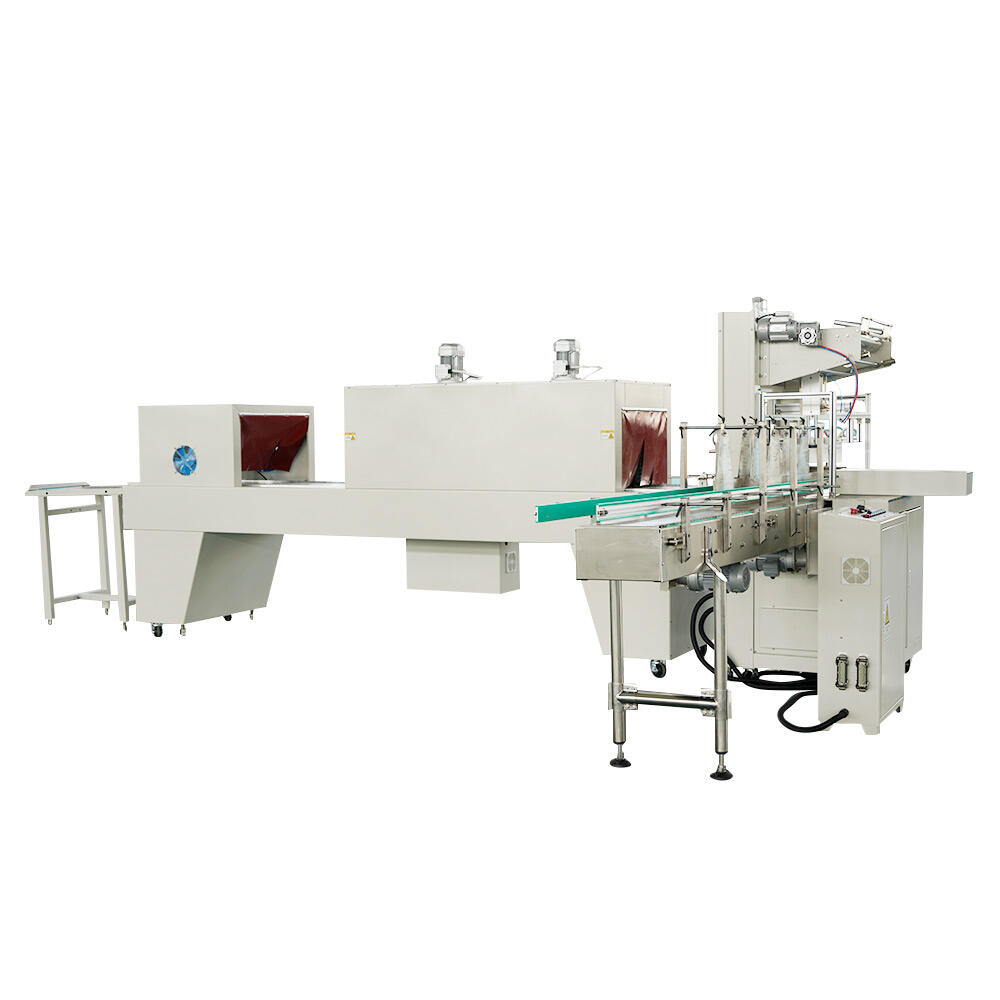

heat shrink packing machine

The heat shrink packing machine represents a cutting-edge solution in modern packaging technology, designed to efficiently wrap and protect products using heat-shrinkable film. This sophisticated equipment operates by automatically enveloping items in specialized plastic film and applying controlled heat to create a tight, professional seal. The machine's core functionality includes precise temperature control systems, adjustable conveyor speeds, and automated film feeding mechanisms. It can handle various product sizes and shapes through its customizable tunnel dimensions and temperature settings. The technology incorporates advanced heating elements that ensure uniform heat distribution, resulting in consistent shrinkage and optimal package appearance. These machines typically feature stainless steel construction for durability and compliance with food-grade requirements, making them suitable for diverse industries including food and beverage, pharmaceuticals, and consumer goods. The process begins with product loading, followed by film wrapping, heat shrinking in the tunnel, and final cooling for package stability. Modern versions include digital control panels for precise operation parameters, energy-efficient heating systems, and safety features such as emergency stops and temperature limiters. The machine's versatility allows it to accommodate both individual items and bundled products, making it an essential tool for businesses seeking efficient, professional packaging solutions.