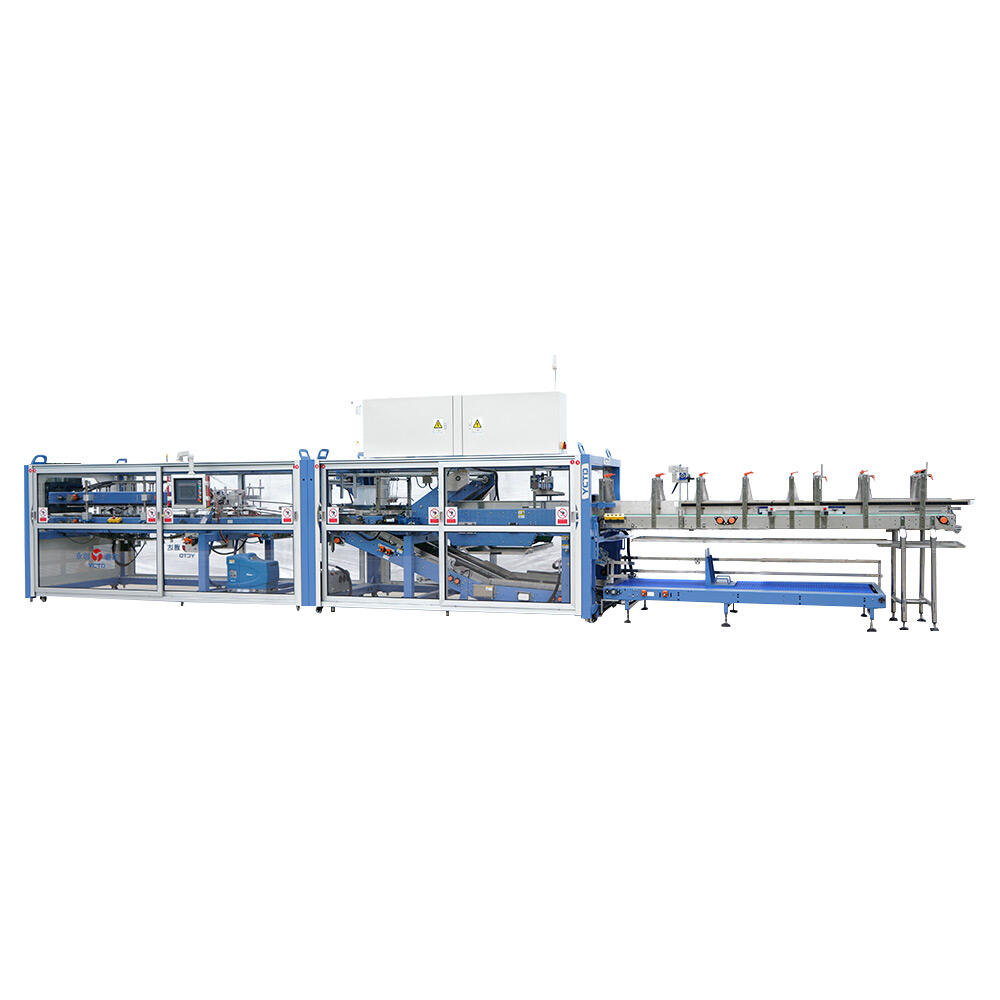

bottle packaging machine

The bottle packaging machine represents a cornerstone of modern industrial automation, designed to streamline the packaging process for various liquid and solid products. This sophisticated equipment combines precision engineering with advanced automation to handle multiple packaging tasks, including bottle sorting, filling, capping, labeling, and final packaging. The machine's integrated system can process different bottle sizes and materials, from plastic to glass containers, with remarkable efficiency. Operating at speeds of up to 200 bottles per minute, these machines incorporate smart sensors and quality control mechanisms to ensure consistent packaging quality. The system features adjustable filling heads, automated cap tightening mechanisms, and precision labeling systems that maintain optimal positioning and product presentation. Advanced control systems allow for real-time monitoring and adjustments, while the modular design enables easy maintenance and quick format changes. The machine's versatility extends to various industries, including beverage, pharmaceutical, chemical, and cosmetic sectors, making it an essential component in modern manufacturing facilities. Safety features include emergency stop systems, guard doors, and protective enclosures to ensure operator safety while maintaining productivity.