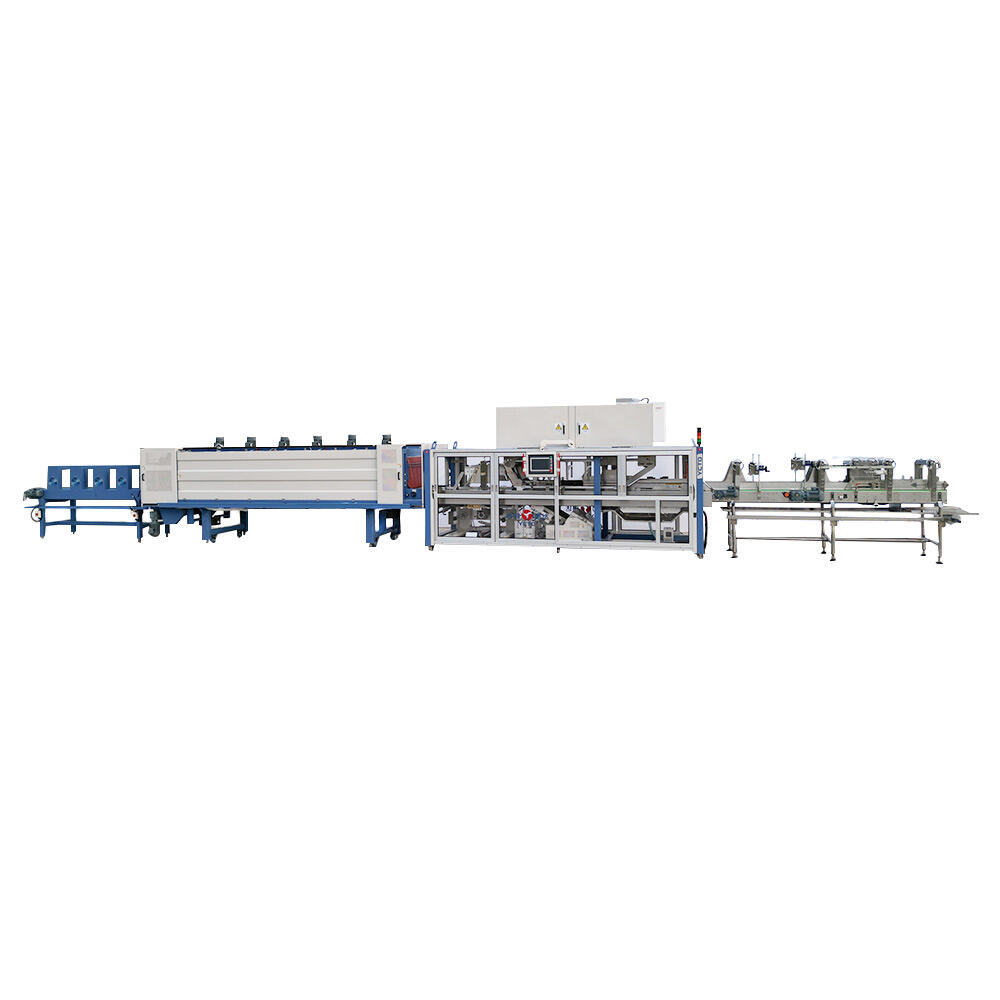

shrink packaging equipment

Shrink packaging equipment represents a cornerstone of modern industrial packaging solutions, offering automated and efficient means of securing products in protective film. These machines utilize thermal technology to wrap items in heat-sensitive plastic film, which shrinks tightly around the product when exposed to controlled heat. The equipment typically consists of multiple components, including a wrapping mechanism, heat tunnel, and conveyor system. Advanced models feature precise temperature controls, adjustable conveyor speeds, and multiple heating zones to ensure optimal shrinkage across various product sizes. The technology employs either polyolefin or PVC shrink films, creating a tight, protective seal that enhances product presentation while providing protection during storage and transportation. These systems can handle products of various dimensions, from small consumer goods to large industrial items, with production speeds ranging from 10 to 100 packages per minute depending on the model. Modern shrink packaging equipment incorporates smart controls, energy-efficient heating elements, and automated feed systems, making them suitable for both small-scale operations and high-volume production environments.