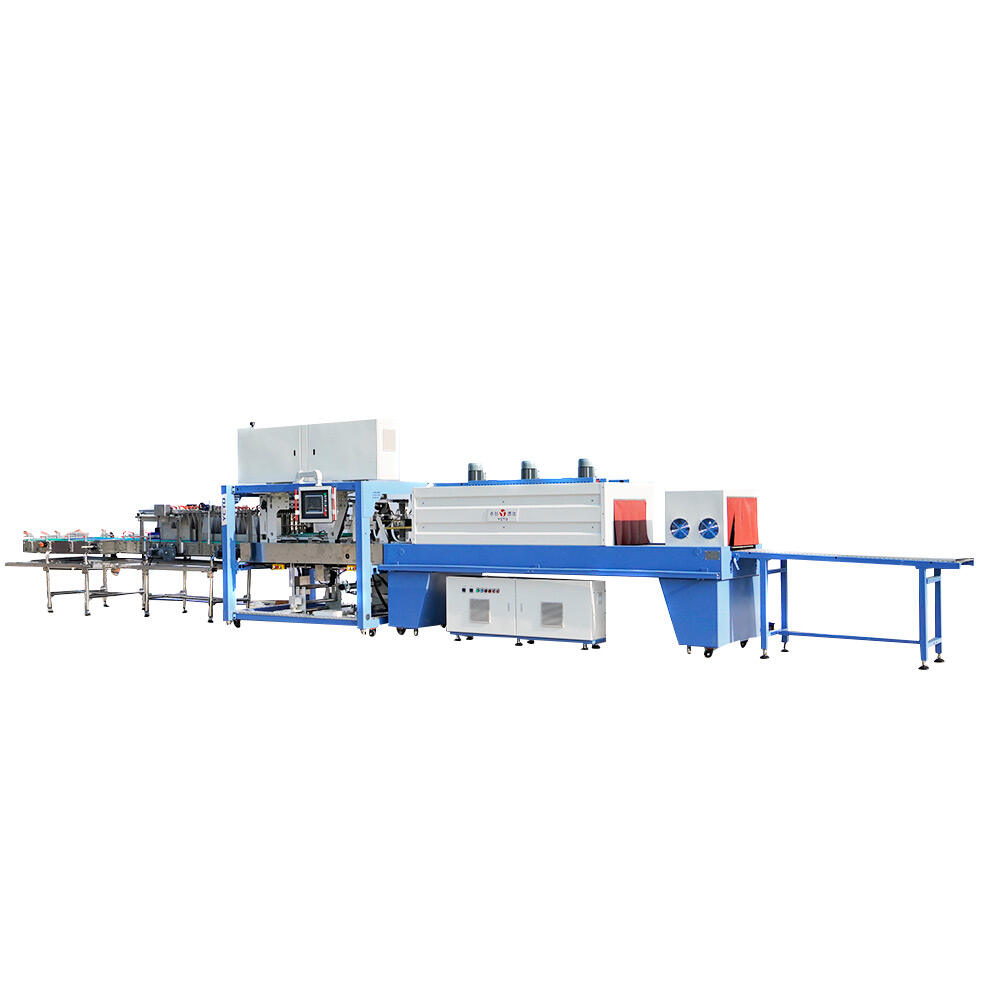

shrink packaging machine manufacturer

A shrink packaging machine manufacturer stands at the forefront of modern packaging solutions, specializing in the design and production of advanced equipment that revolutionizes product packaging processes. These manufacturers develop sophisticated machines that utilize heat-shrink technology to create secure, attractive, and professional packaging for various products. Their machines incorporate cutting-edge features including precision temperature control systems, adjustable sealing mechanisms, and automated conveyor systems that ensure consistent packaging quality. The equipment produced ranges from compact manual systems to fully automated industrial-scale solutions, capable of handling diverse product sizes and shapes. These manufacturers prioritize energy efficiency and operational reliability, implementing smart controls and user-friendly interfaces that simplify operation while maintaining high production standards. Their machines feature advanced safety mechanisms, quality control systems, and modular designs that allow for future upgrades and customization. The manufacturers also provide comprehensive support services, including installation, training, and maintenance programs to ensure optimal performance throughout the machine's lifecycle. Their commitment to innovation is reflected in continuous research and development efforts, resulting in machines that meet evolving industry demands for speed, efficiency, and sustainability.