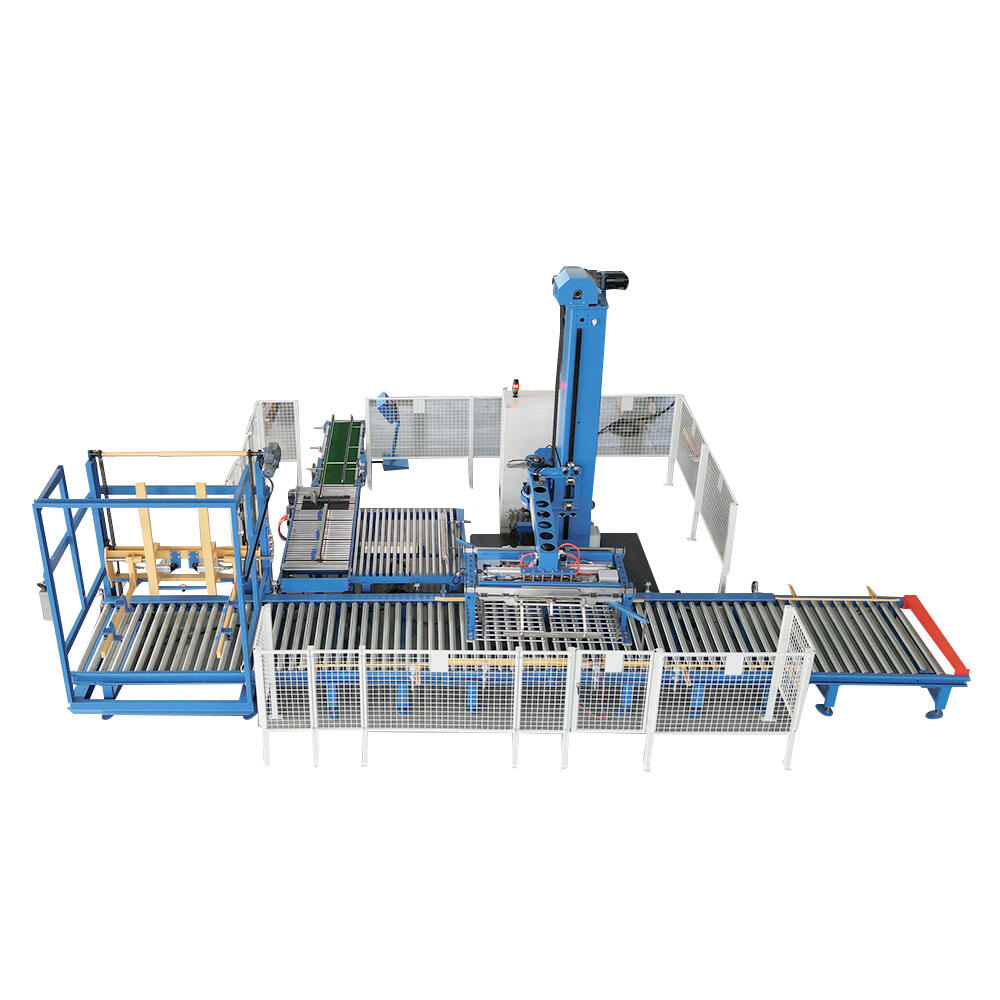

ماكينة تحميل الزجاجات على المنصات

إن آلة تكديس الزجاجات على المنصات هي نظام آلي متقدم تم تصميمه لتوزيع الزجاجات وتكديسها على المنصات بكفاءة من أجل التخزين والنقل. تجمع هذه الآلة المتطورة بين هندسة دقيقة وأتمتة ذكية لمعالجة أحجام وأنواع مختلفة من الزجاجات، مما يسهم في تبسيط عملية التعبئة في نهاية الخط الإنتاجي. تتكون هذه الآلة عادةً من عدة مكونات، منها ناقل تغذية الزجاجات، وآلية تشكيل الصفوف، ومحطة إعداد الطبقات، والوحدة الرئيسية لتكديس الزجاجات على المنصات. تحتوي آلات تكديس الزجاجات الحديثة على أجهزة استشعار ووحدات تحكم منطقية قابلة للبرمجة (PLCs) تضمن تحديد المواقع بدقة ومعالجة الزجاجات برفق لمنع التلف مع الحفاظ على معدلات إنتاج عالية. يمكن لهذه الآلات معالجة مواد مختلفة تشمل الزجاج والبلاستيك والحاويات المعدنية، مما يجعلها حلولًا متعددة الاستخدامات لمصنعي المشروبات وشركات الأدوية وصناعات الكيماويات. تعتمد التقنية المستخدمة أنظمة متقدمة للتعرف على الأنماط وللتحكم في الحركة من أجل تشكيل أحمال مستقرة ومنظمة على المنصات، مما يحسن استخدام المساحة ويضمن التعامل الآمن مع المنتجات أثناء التخزين والنقل. كما تتميز العديد من الموديلات الحديثة واجهات سهلة الاستخدام تتيح للمشغلين تعديل المعايير بسهولة وفقًا لمواصفات الزجاجات المختلفة وأنماط المنصات، مما يعزز المرونة والكفاءة في التشغيل.