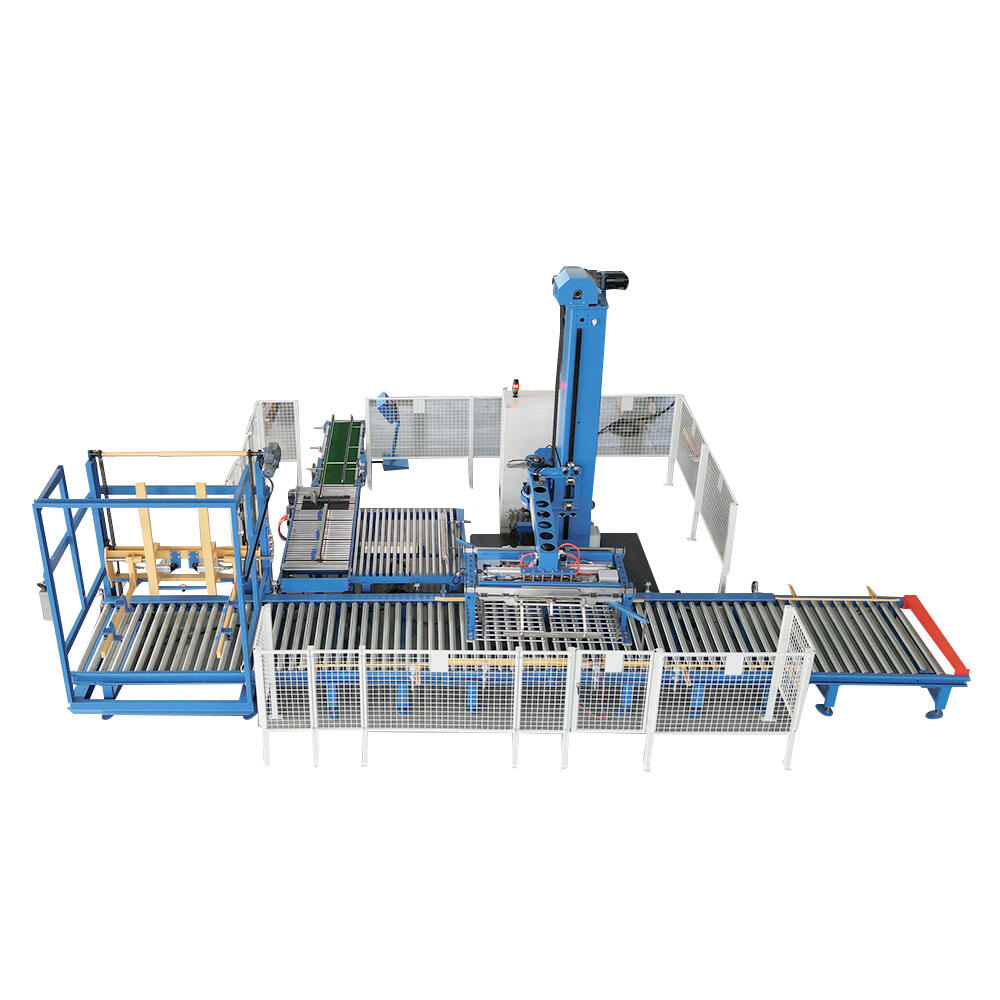

bottle palletizer

A bottle palletizer is an advanced automated system designed to efficiently arrange and stack bottles onto pallets for storage and transportation. This sophisticated machinery combines precision engineering with smart automation to handle various bottle sizes and types, streamlining the end-of-line packaging process. The system typically consists of multiple components, including a bottle infeed conveyor, row formation mechanism, layer preparation station, and the main palletizing unit. Modern bottle palletizers incorporate sensors and programmable logic controllers (PLCs) that ensure accurate positioning and gentle handling of bottles, preventing damage while maintaining high throughput rates. These machines can process different materials including glass, plastic, and metal containers, making them versatile solutions for beverage manufacturers, pharmaceutical companies, and chemical industries. The technology employs advanced pattern recognition and motion control systems to create stable, well-organized pallet loads that optimize space utilization and ensure safe product handling during storage and transportation. Many contemporary models feature user-friendly interfaces that allow operators to easily adjust parameters for different bottle specifications and pallet patterns, enhancing operational flexibility and efficiency.