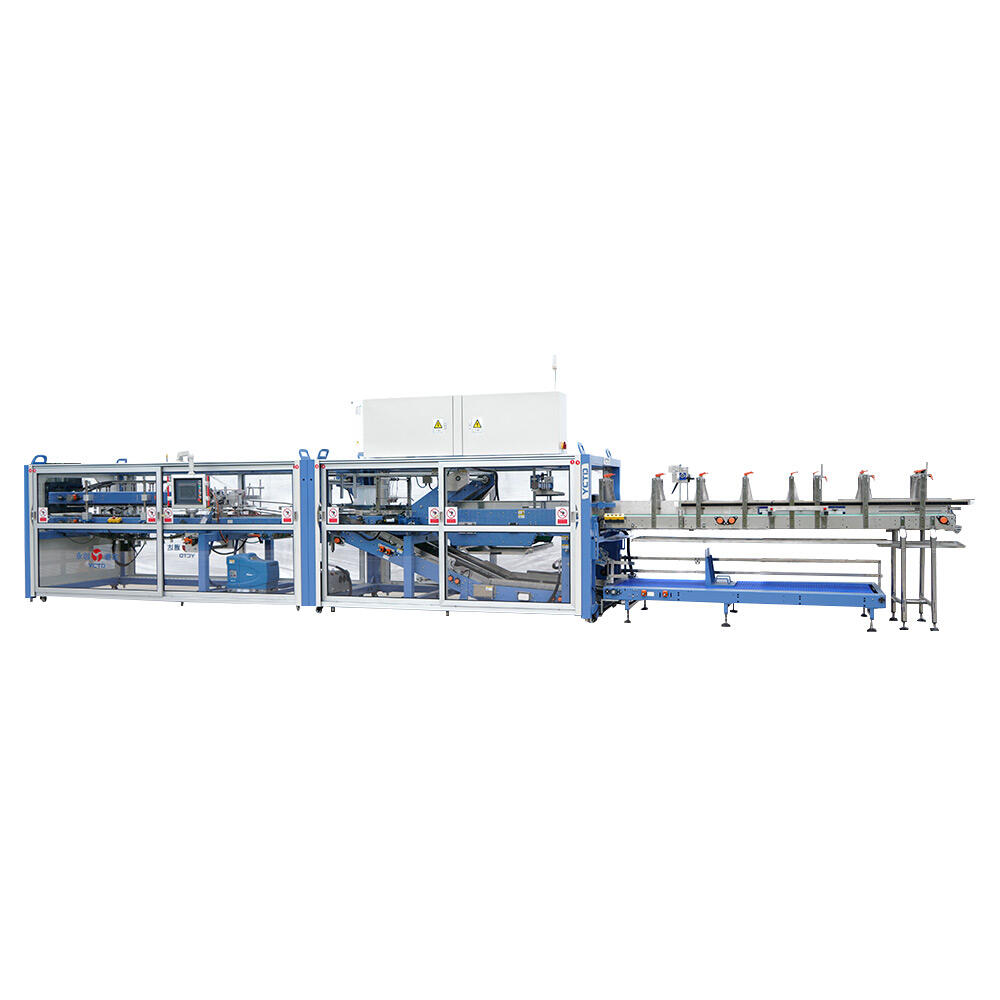

լավագույն տուփերի փաթեթավորող

Լավագույն տուփերի փաթեթավորման մեքենան ներկայացնում է փաթեթավորման գործողությունների ավտոմատացման ամենանոր տեխնոլոգիան, ապահովելով աննախադեպ արդյունավետություն և հուսանքային աշխատանք ժամանակակից արտադրական միջավայրում։ Այս առաջադեմ սարքավորումը համատեղելի է գործող արտադրական գծերի հետ, ճշգրիտ և արագ կերպով մշակելով տարբեր տուփերի ձևաչափեր և ապրանքների տեսակներ։ Համակարգը օգտագործում է բարդ սերվո-վարիչային տեխնոլոգիա՝ ապահովելով ճշգրիտ ապրանքների տեղադրում և հաստատուն տուփերի ձևավորում, իսկ դրա ինտուիտիվ HMI ինտերֆեյսը թույլ է տալիս արագ ձևաչափերի փոփոխություն և գործողությունների իրական ժամանակի հսկում։ Տուփերի փաթեթավորման սարքը ունի մոդուլային կառուցվածք, որը թույլ է տալիս տարբեր մուտքային կազմաձևեր, ներառյալ հորիզոնական և ուղղահայաց բեռնման տարբերակներ, դա այնքան բազմակողմանի է, որ կարող է մշակել շիշեր, տոպրակներ, տուփեր և այլ փաթեթավորման ձևաչափեր։ Մինչև 30 տուփ մեկ րոպեում մշակելու արագությամբ, մեքենան պահպանում է օպտիմալ արդյունավետությունը՝ ներառելով անվտանգության հնարավորություններ, ինչպիսիք են վթարային կանգները և պաշտպանական դռների փոխանցման փականները։ Համակարգի ամուր կառուցվածքը երկար կյանք է ապահովում և նվազագույն նորոգման կարիք, իսկ դրա փոքր տարածքը առավելագույնս օգտագործում է հատակի տարածքը։ Առաջադեմ զգայուն տեխնոլոգիան կանխում է ապրանքների վնասումը և ապահովում ճշգրիտ տուփերի ձևավորում, փակում և կոդավորման գործողությունները։