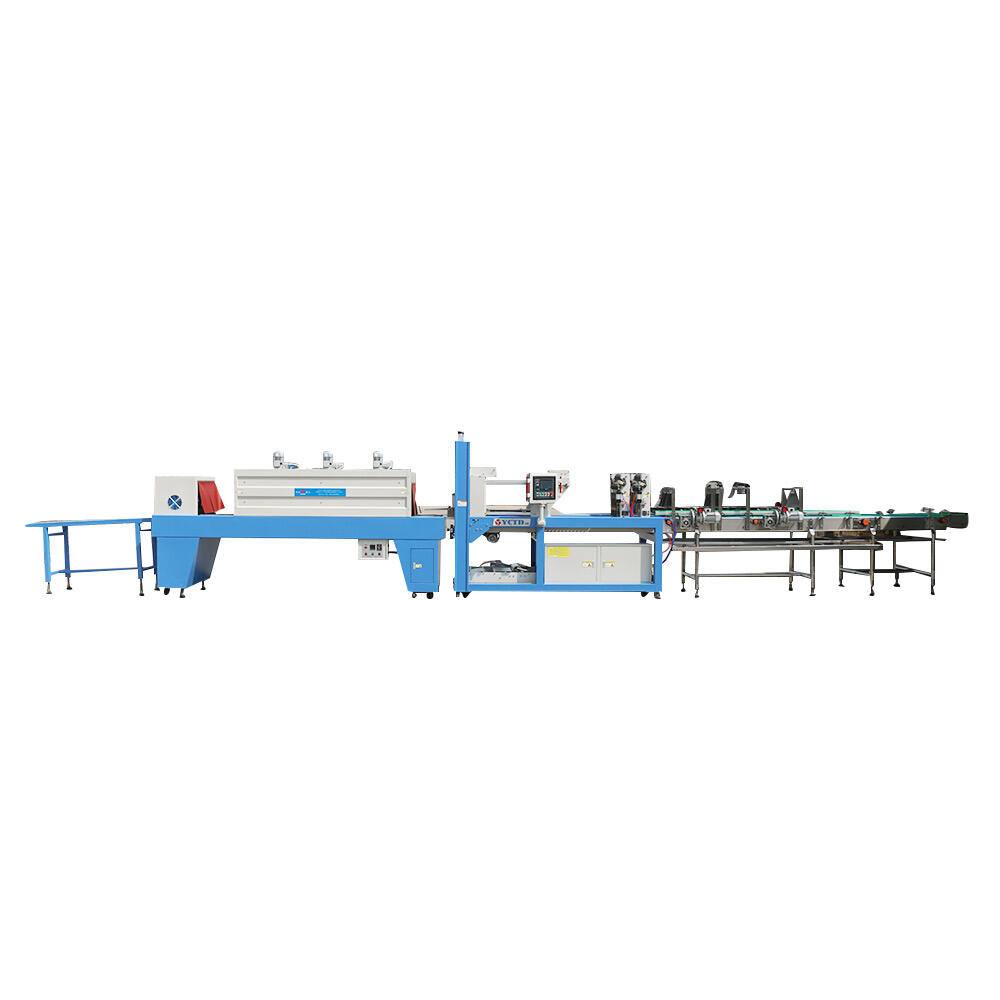

food packaging equipment

Food packaging equipment represents a crucial component in modern food processing and manufacturing facilities, incorporating advanced automation and precision engineering to ensure safe, efficient, and consistent packaging operations. These sophisticated systems handle various tasks, from primary food containment to secondary packaging and palletizing, utilizing cutting-edge technology to maintain product integrity and extend shelf life. The equipment typically includes filling machines, sealing units, labeling systems, and quality control mechanisms, all working in harmony to deliver precise portion control and tamper-evident packaging. Modern food packaging equipment features smart controls with touchscreen interfaces, allowing operators to monitor and adjust parameters in real time. The systems are designed with hygienic principles in mind, incorporating stainless steel construction and easy-clean surfaces that comply with stringent food safety regulations. These machines can handle different packaging materials and formats, from flexible pouches to rigid containers, accommodating various food products ranging from liquids and powders to solid items. The integration of IoT capabilities enables remote monitoring, predictive maintenance, and data analytics for optimized performance and reduced downtime.