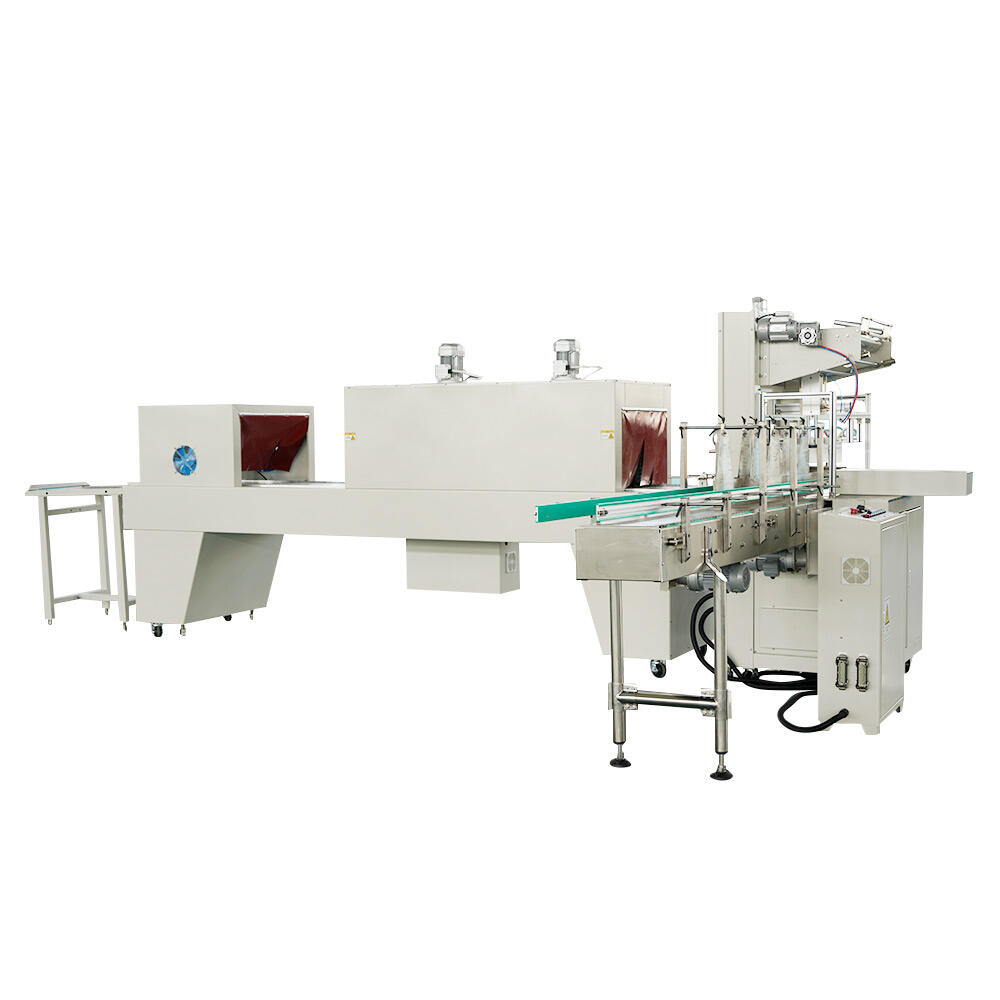

liquid packaging machine

A liquid packaging machine is an advanced automated system designed to efficiently fill, seal, and package various liquid products in containers. These versatile machines handle everything from beverages and dairy products to chemicals and pharmaceuticals. The system typically incorporates multiple stations that work in harmony, including container feeding, filling, capping, labeling, and discharge mechanisms. Modern liquid packaging machines feature precision volume control systems, ensuring accurate dispensing through advanced flow meters and level sensors. They operate with sophisticated PLC controls that maintain consistent operation speeds while monitoring all critical parameters. The machines are built with sanitary stainless steel construction, meeting strict hygiene standards for food and beverage processing. Many models offer customizable filling heads to accommodate different container sizes and shapes, with quick-change mechanisms for rapid product changeovers. Safety features include emergency stop systems, guard doors with interlocks, and overflow protection. These machines can achieve impressive throughput rates, often processing hundreds of containers per minute while maintaining precise fill levels and minimal product waste. The integration of servo motors enables smooth operation and precise positioning, while advanced sealing systems ensure product integrity and shelf life.