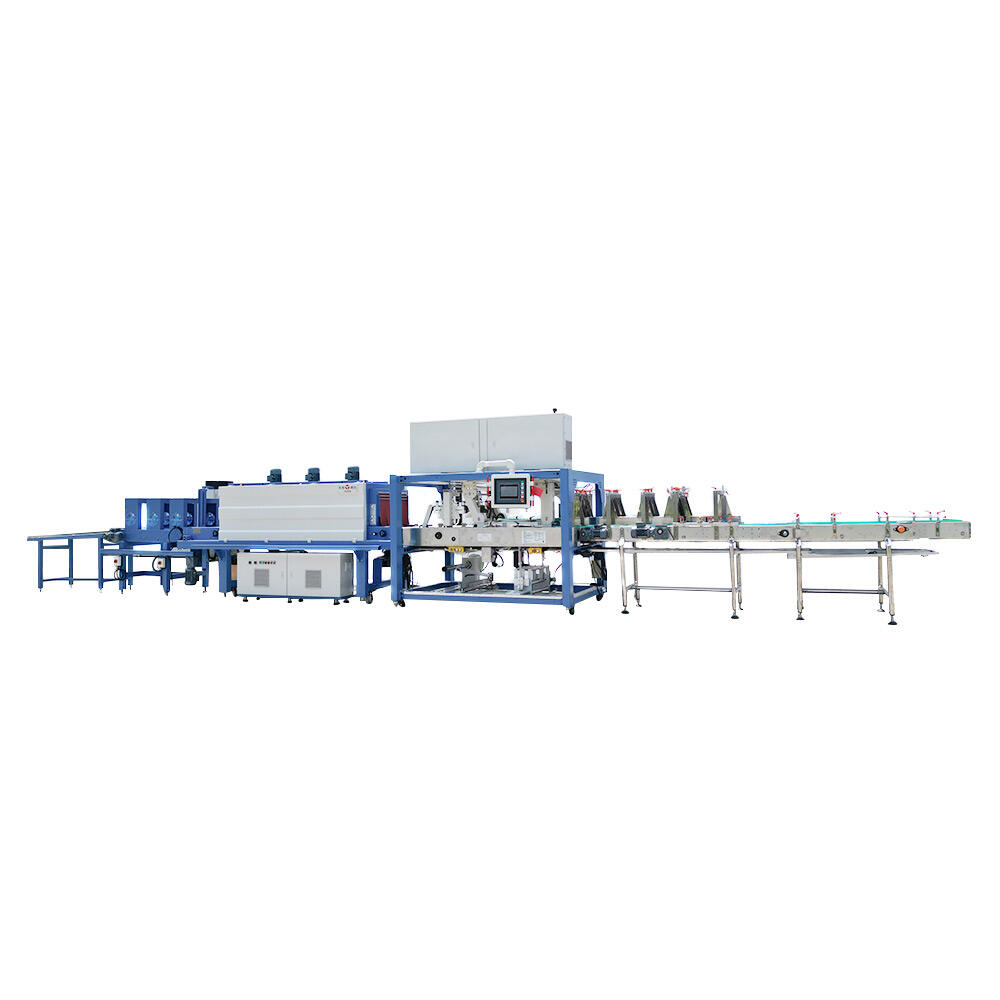

heat shrink tunnel machine for bottles

The heat shrink tunnel machine for bottles is an advanced packaging solution designed to efficiently apply shrink sleeve labels to various types of containers. This sophisticated equipment utilizes controlled heat distribution to ensure uniform shrinkage of sleeve labels, resulting in a seamless, professional finish. The machine features a carefully engineered tunnel system where bottles pass through multiple temperature zones, allowing for precise heat application that activates the shrink material. With adjustable conveyor speeds and temperature controls, the system can accommodate different bottle sizes and shapes, ranging from small cosmetic containers to large beverage bottles. The technology incorporates advanced heat circulation methods that ensure even distribution of hot air, preventing potential distortion or uneven shrinkage. Modern heat shrink tunnels are equipped with energy-efficient heating elements and intelligent temperature management systems that optimize power consumption while maintaining consistent performance. The machine's versatile design allows for integration into existing production lines, offering both standalone operation and seamless incorporation into automated packaging systems. Its applications span across various industries, including beverages, cosmetics, pharmaceuticals, and household products, making it an essential tool for businesses seeking professional packaging solutions.