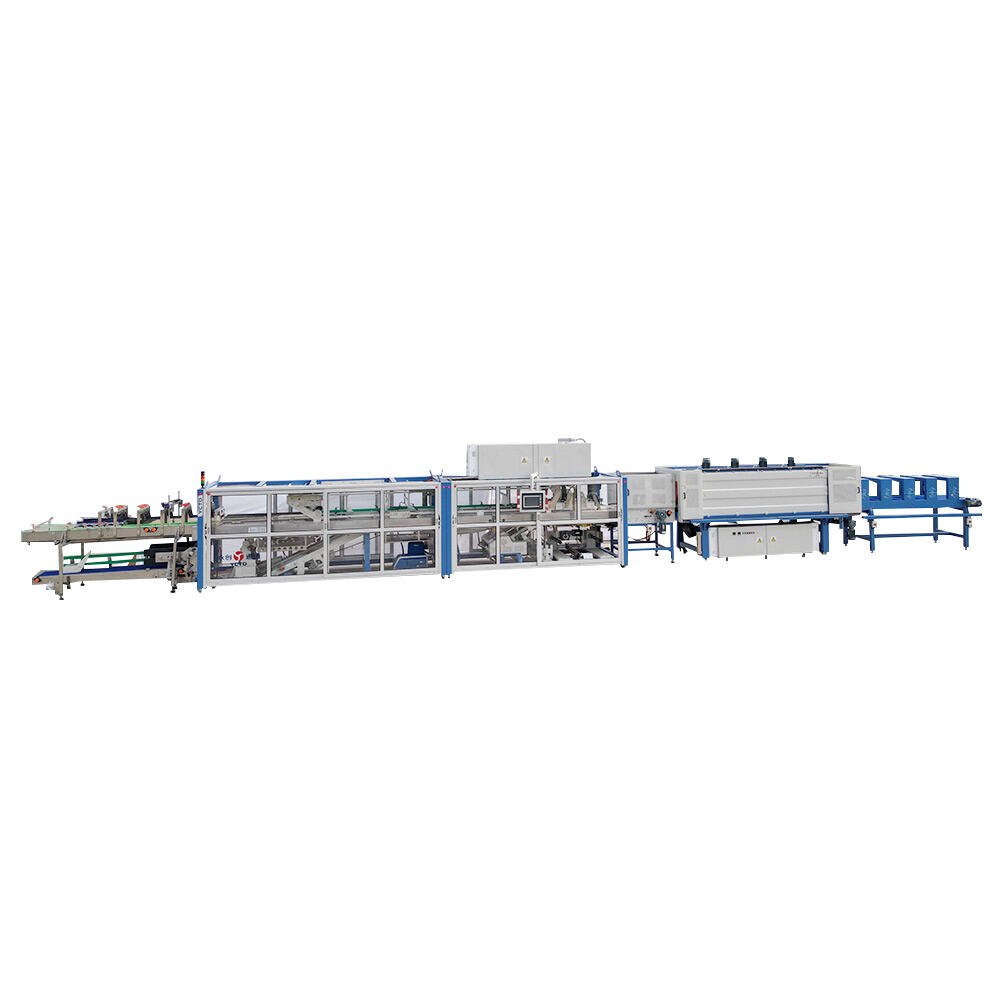

small shrink tunnel machine

The small shrink tunnel machine represents a compact yet powerful solution for packaging operations, designed to efficiently apply heat shrink packaging to various products. This versatile machine utilizes advanced heating technology to create a uniform shrinking process, ensuring professional-looking results every time. The tunnel operates by generating consistent heat distribution through its carefully engineered chamber, where products pass on a conveyor belt system. The temperature can be precisely controlled to accommodate different shrink film materials and product requirements, typically ranging from 50°C to 200°C. The machine features adjustable belt speed controls, allowing operators to optimize the shrinking process for different product sizes and packaging materials. With its space-saving design, typically measuring between 1-1.5 meters in length, the small shrink tunnel machine is ideal for businesses with limited floor space. The system incorporates energy-efficient heating elements that quickly reach optimal operating temperature while maintaining low power consumption. Safety features include thermal insulation and emergency stop functions, ensuring operator protection during operation. The machine's versatility allows it to handle various products, from small individual items to bundled packages, making it suitable for industries ranging from food and beverage to cosmetics and retail products.