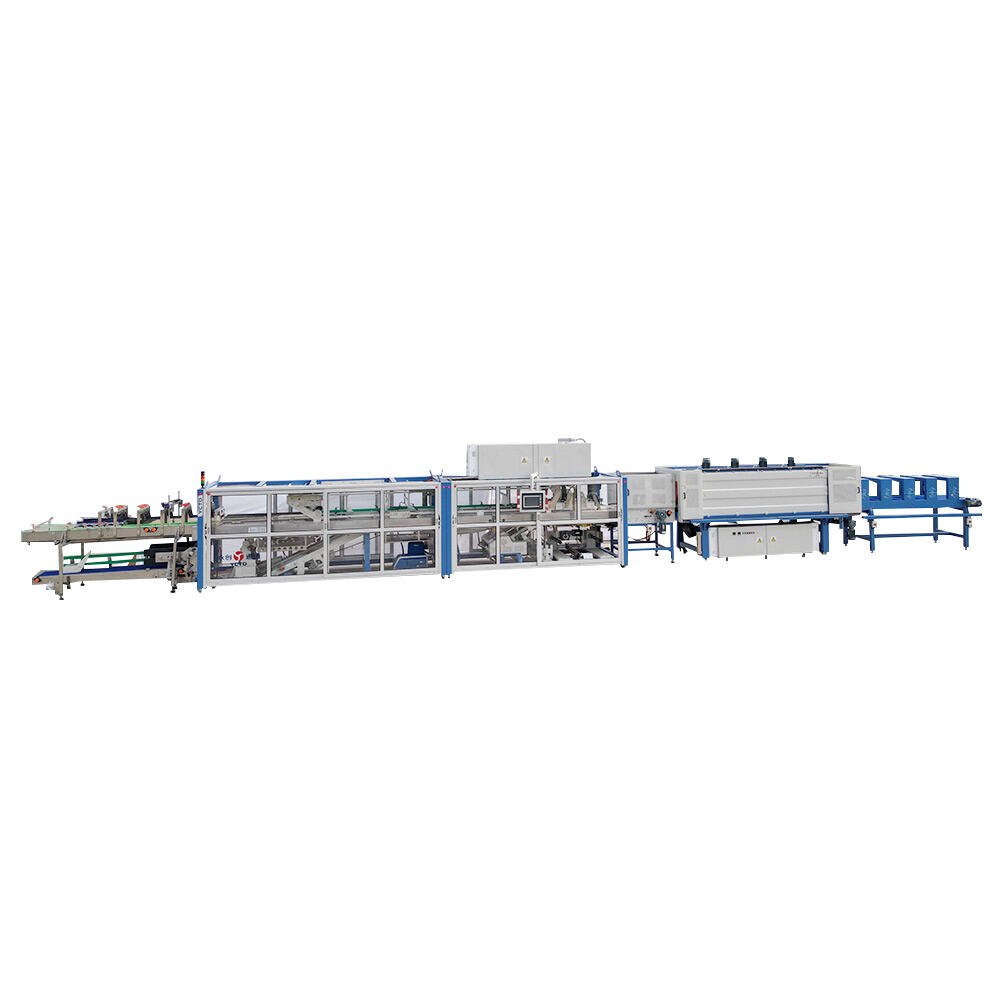

shrink wrap heat tunnel

A shrink wrap heat tunnel is a sophisticated packaging solution that revolutionizes the way products are wrapped and sealed. This advanced system consists of a temperature-controlled chamber through which products pass on a conveyor belt, allowing for consistent and professional shrink wrapping results. The tunnel creates a controlled environment where heat is evenly distributed, causing the shrink wrap film to contract uniformly around products of various sizes and shapes. Operating at temperatures typically ranging from 300-400°F (149-204°C), these tunnels can process items continuously, making them ideal for high-volume production environments. The system features adjustable temperature controls, variable belt speeds, and multiple heat zones that ensure optimal shrinking conditions for different film types and product requirements. Modern shrink wrap heat tunnels incorporate energy-efficient heating elements and advanced insulation materials to minimize heat loss and reduce operating costs. The tunnel's design includes precise airflow management systems that maintain consistent temperature distribution, preventing hot spots and ensuring uniform shrinkage. This technology is particularly valuable in industries such as food and beverage, pharmaceuticals, cosmetics, and retail, where product presentation and protection are paramount.