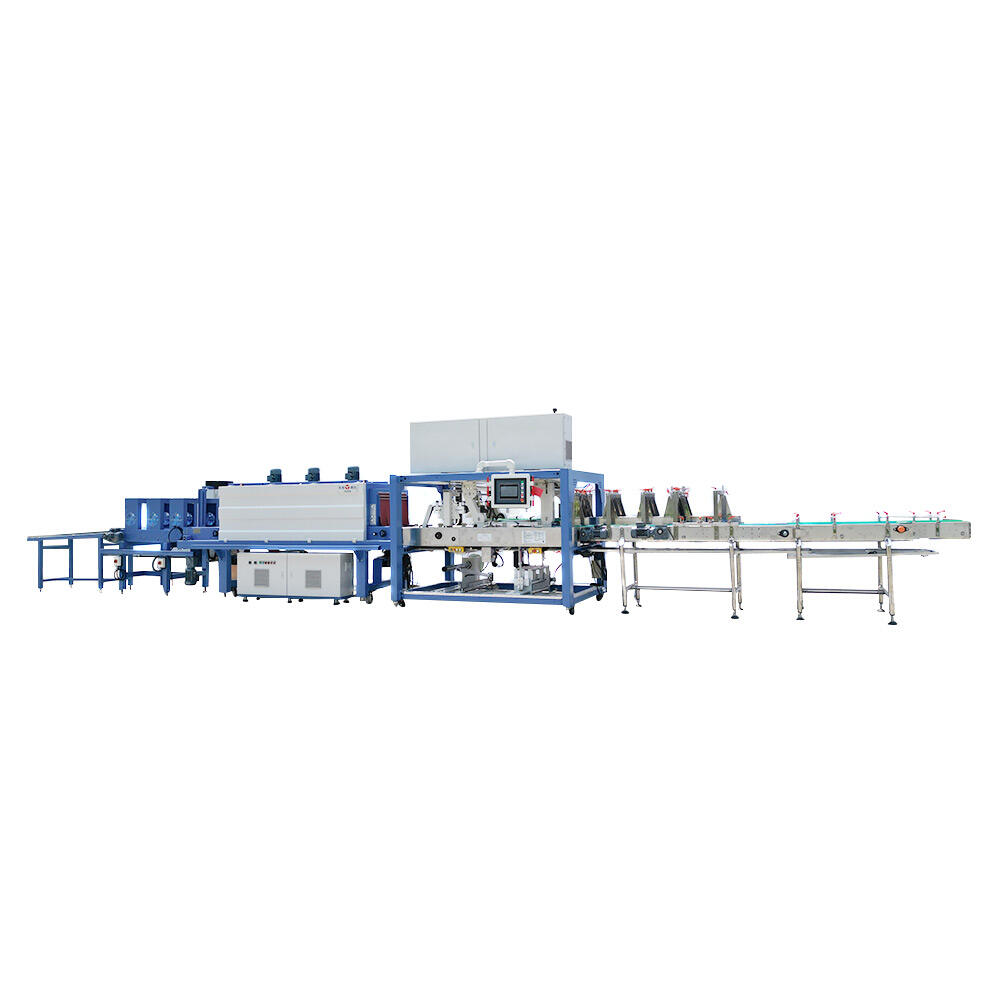

manual shrink wrap machine

A manual shrink wrap machine is a versatile packaging solution designed for businesses seeking efficient and cost-effective product protection. This equipment consists of a sealing mechanism and a heat shrink system that works together to create professional-looking, secure packaging. The machine typically features an L-bar sealer that simultaneously seals two sides of the shrink film, allowing operators to quickly wrap products of various sizes. The heating element maintains consistent temperature control, ensuring uniform shrinkage of the film around the product. The machine's adjustable work surface accommodates different product dimensions, while the built-in timer helps maintain precise sealing durations. Most models include a film roll holder and cutting mechanism for smooth film dispensing and clean cuts. These machines are engineered with safety features such as temperature controls and cool-down systems to protect operators. The simple yet effective design allows for easy maintenance and operation, making it ideal for small to medium-sized businesses. Whether packaging single items or bulk products, the manual shrink wrap machine delivers professional results while requiring minimal training and setup time.