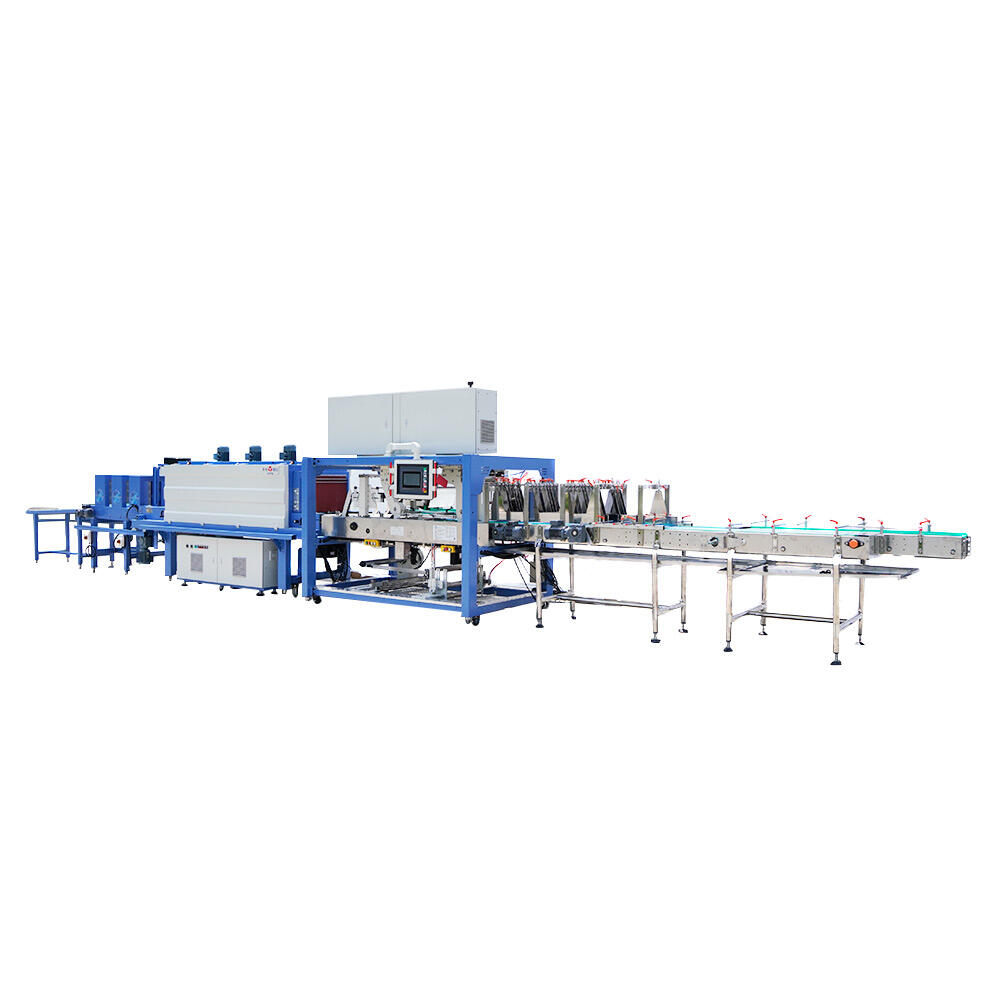

shrink wrap manufacturing machine

The shrink wrap manufacturing machine represents a pinnacle of modern packaging technology, designed to efficiently produce high-quality shrink wrap films for various industrial applications. This sophisticated equipment utilizes advanced extrusion technology to transform raw plastic pellets into uniform, durable shrink film. The machine incorporates a precise temperature control system that ensures consistent melting and cooling of materials, resulting in superior film quality. At its core, the manufacturing process begins with the feeding system, where plastic resins are carefully measured and introduced into the heating chamber. The material then passes through an advanced die system that forms it into a tubular shape, followed by precise biaxial orientation that enhances the film's strength and shrinkage properties. The machine features multiple heating zones that can be independently controlled, allowing for optimal processing of different material types and thicknesses. Modern shrink wrap manufacturing machines are equipped with digital control panels that enable operators to monitor and adjust production parameters in real-time, ensuring consistent output quality. The system also includes sophisticated winding mechanisms that ensure proper tension control and smooth roll formation. These machines can produce films ranging from 15 to 200 microns in thickness, suitable for packaging everything from small consumer goods to large industrial products.