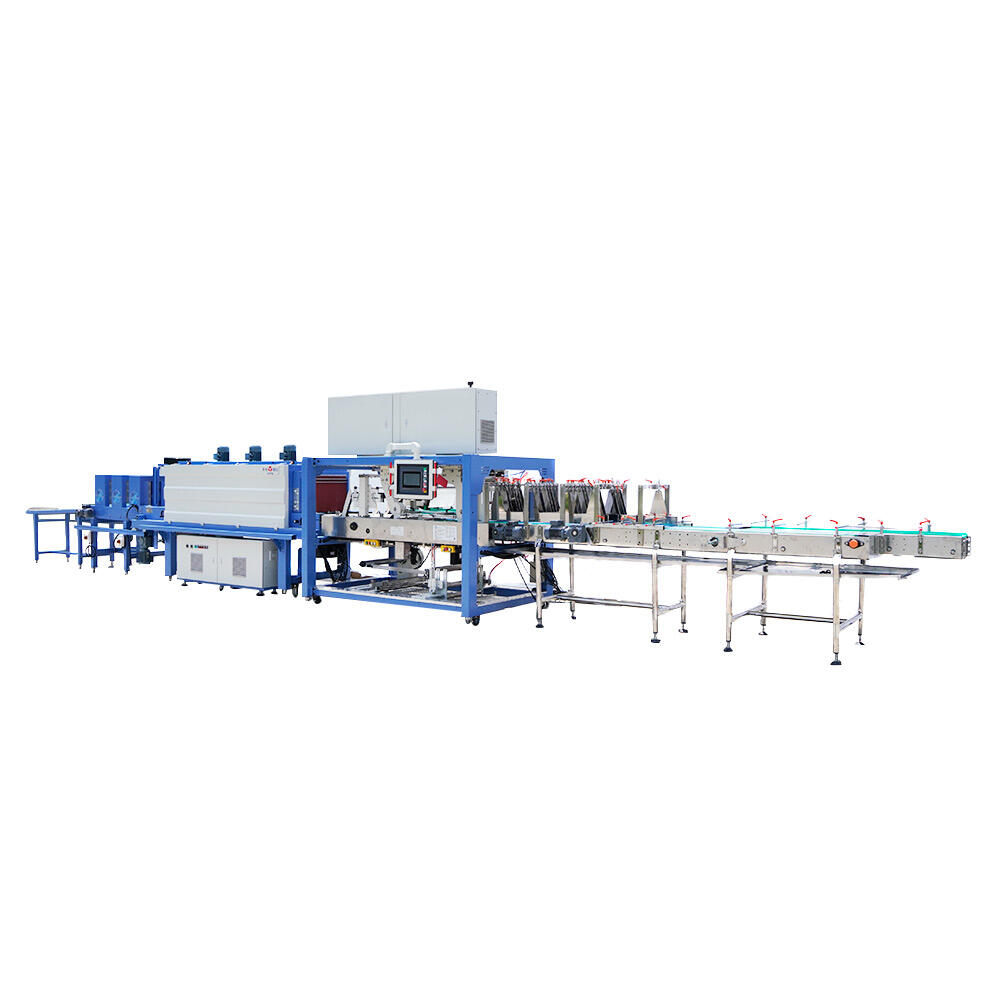

shrink wrap machine industrial

A shrink wrap machine industrial represents a cornerstone of modern packaging technology, designed to efficiently secure and protect products of various sizes and shapes. This sophisticated equipment utilizes heat-shrinking technology to apply a tight, protective film around items, creating a professional and tamper-evident seal. The machine operates through a systematic process, beginning with product placement and film measurement, followed by precise heat application that triggers the shrinking action of the specialized polymer film. Advanced models feature adjustable temperature controls, conveyor systems for continuous operation, and multiple sealing zones to ensure optimal wrapping results. These machines are equipped with digital control panels that allow operators to fine-tune settings for different product specifications and film types. The technology incorporates safety features such as emergency stops and cool-down cycles, while also offering energy-efficient operation through targeted heat distribution. Applications span across numerous industries, from food and beverage packaging to consumer goods, pharmaceuticals, and industrial products. The versatility of these machines enables them to handle both individual items and bundled products, making them essential for businesses seeking to streamline their packaging operations while maintaining high quality standards.