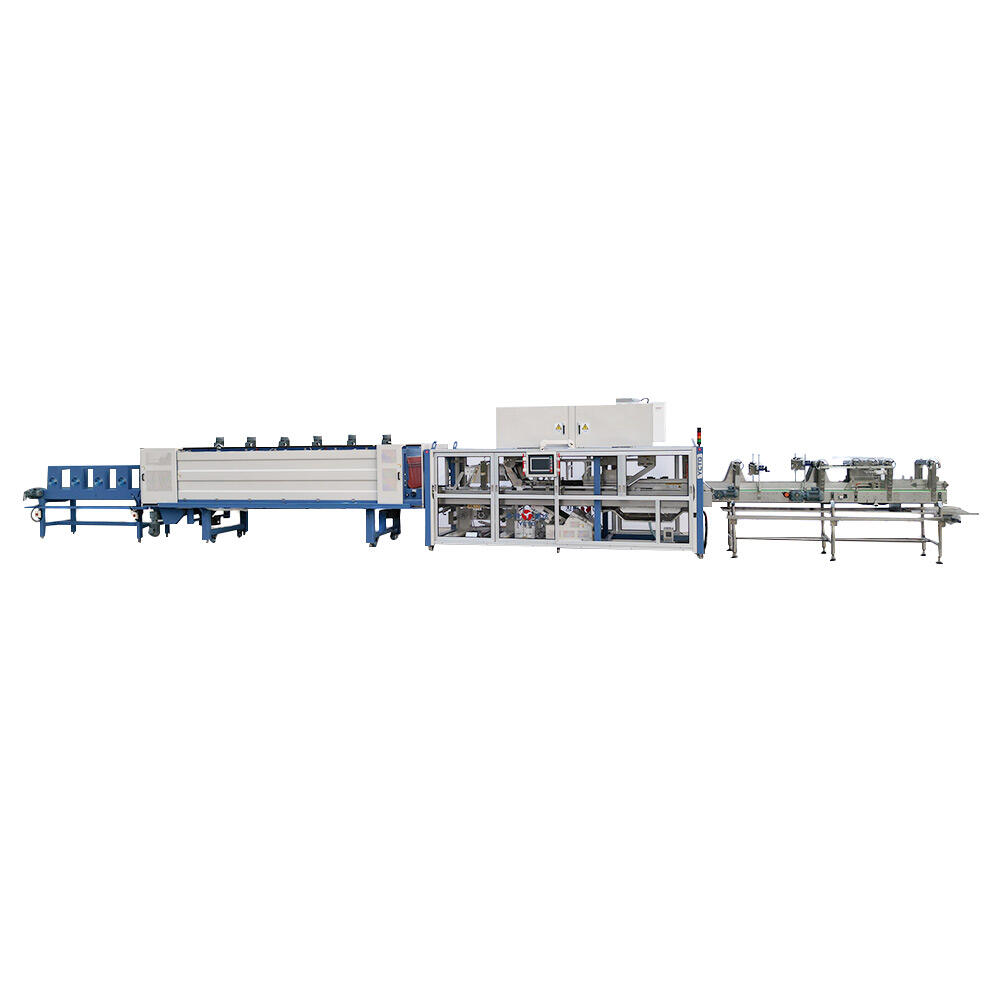

pe shrink film wrapping machine

The PE shrink film wrapping machine represents a cutting-edge solution in modern packaging technology, designed to efficiently wrap products in protective PE shrink film. This versatile equipment combines precision engineering with automated functionality to deliver consistent and professional packaging results. The machine utilizes advanced heating elements to shrink the PE film uniformly around products, creating a tight, secure seal that enhances product presentation and protection. Its intelligent control system allows for precise temperature regulation and belt speed adjustment, ensuring optimal shrinkage without product damage. The machine features an efficient conveyor system that smoothly transports items through multiple stages, including film wrapping, sealing, and shrinking. With adjustable parameters and multiple safety features, it accommodates various product sizes and shapes, making it suitable for industries ranging from food and beverage to consumer goods and industrial products. The system's modular design facilitates easy maintenance and cleaning, while its robust construction ensures long-term reliability and consistent performance. Modern PE shrink film wrapping machines also incorporate energy-saving technologies and smart controls that minimize film waste and optimize operational efficiency.