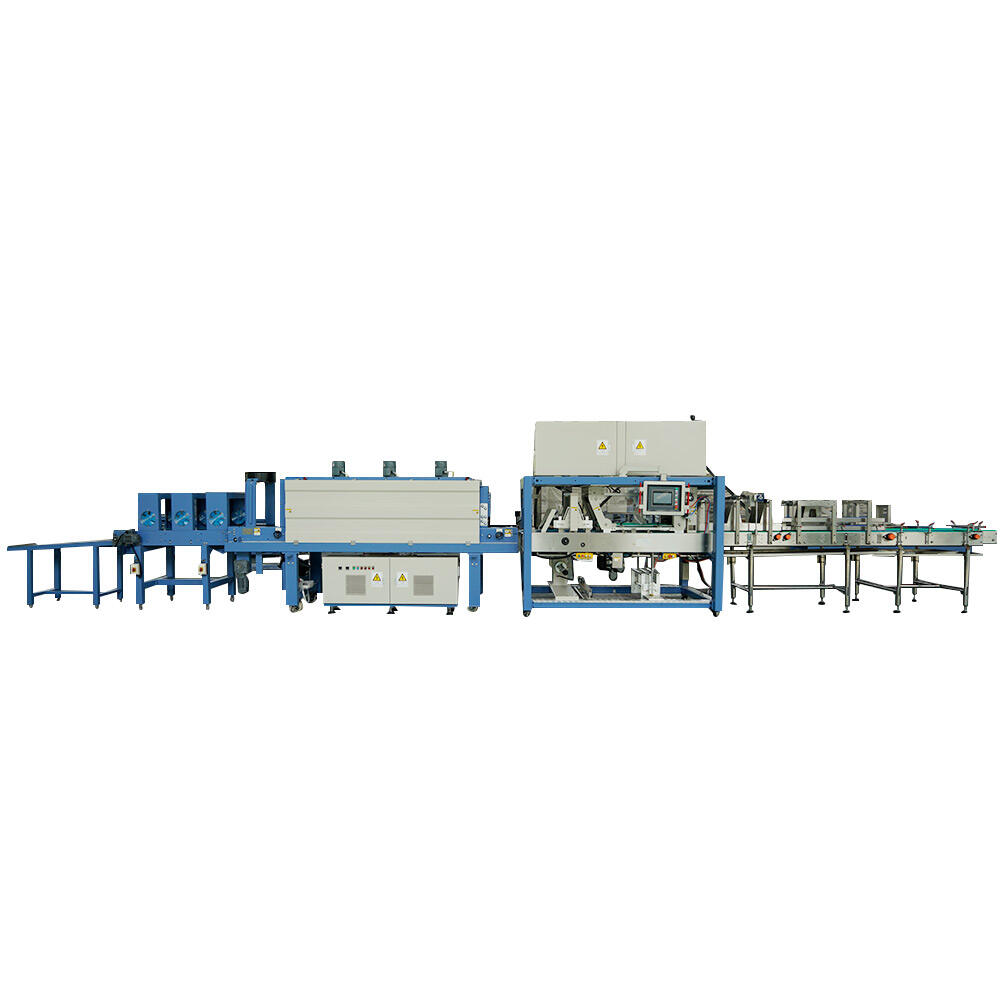

shrink film equipment

Shrink film equipment represents a cutting-edge solution in modern packaging technology, designed to efficiently wrap and protect products through a specialized heating process. This sophisticated machinery comprises multiple components including a shrink tunnel, heat chamber, conveyor system, and temperature controls, working in harmony to deliver precise and consistent packaging results. The equipment operates by passing products through a heated tunnel where the shrink film contracts uniformly around items, creating a tight, protective seal. Advanced temperature regulation systems ensure optimal shrinking conditions, while adjustable conveyor speeds accommodate various product sizes and production volumes. The machinery's versatility allows it to handle diverse items, from single products to bundled packages, making it invaluable across industries such as food and beverage, consumer goods, and retail. Modern shrink film equipment often features digital controls for precise operation, energy-efficient heating systems, and automated product handling capabilities, significantly enhancing production efficiency while maintaining consistent quality standards.