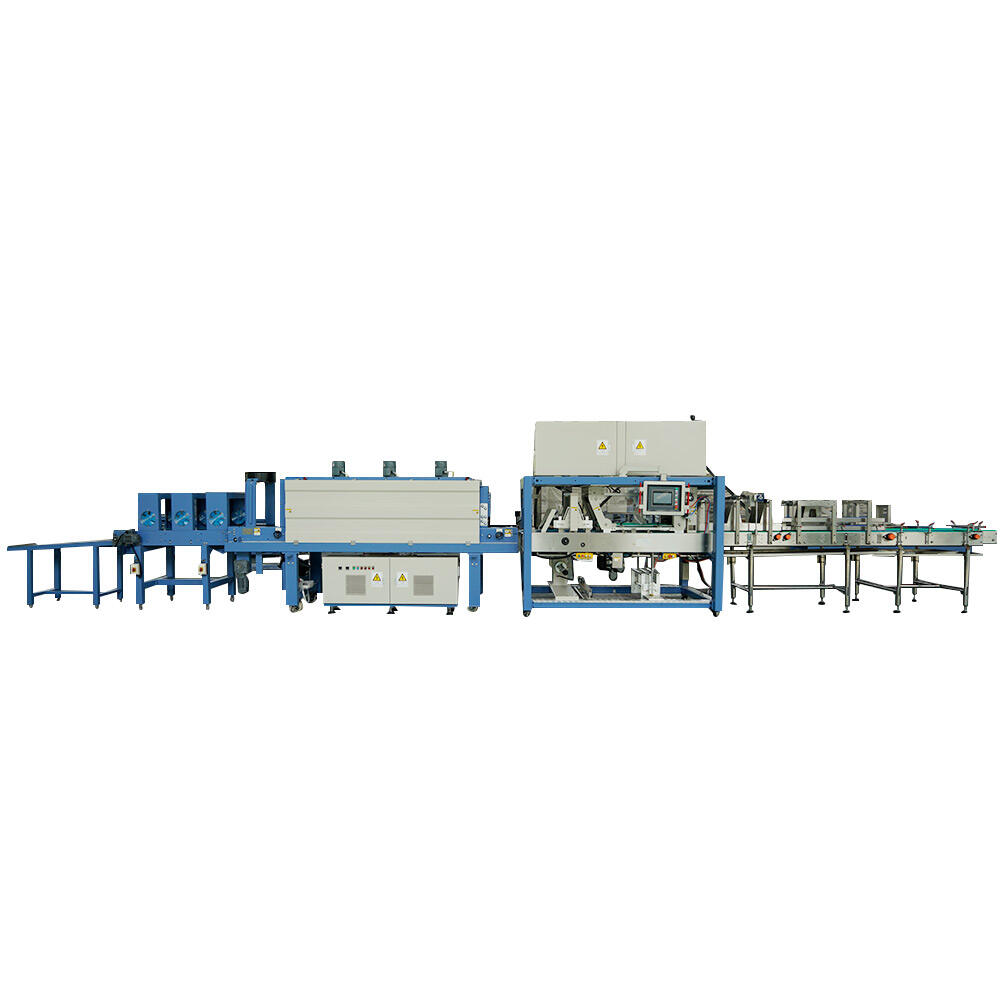

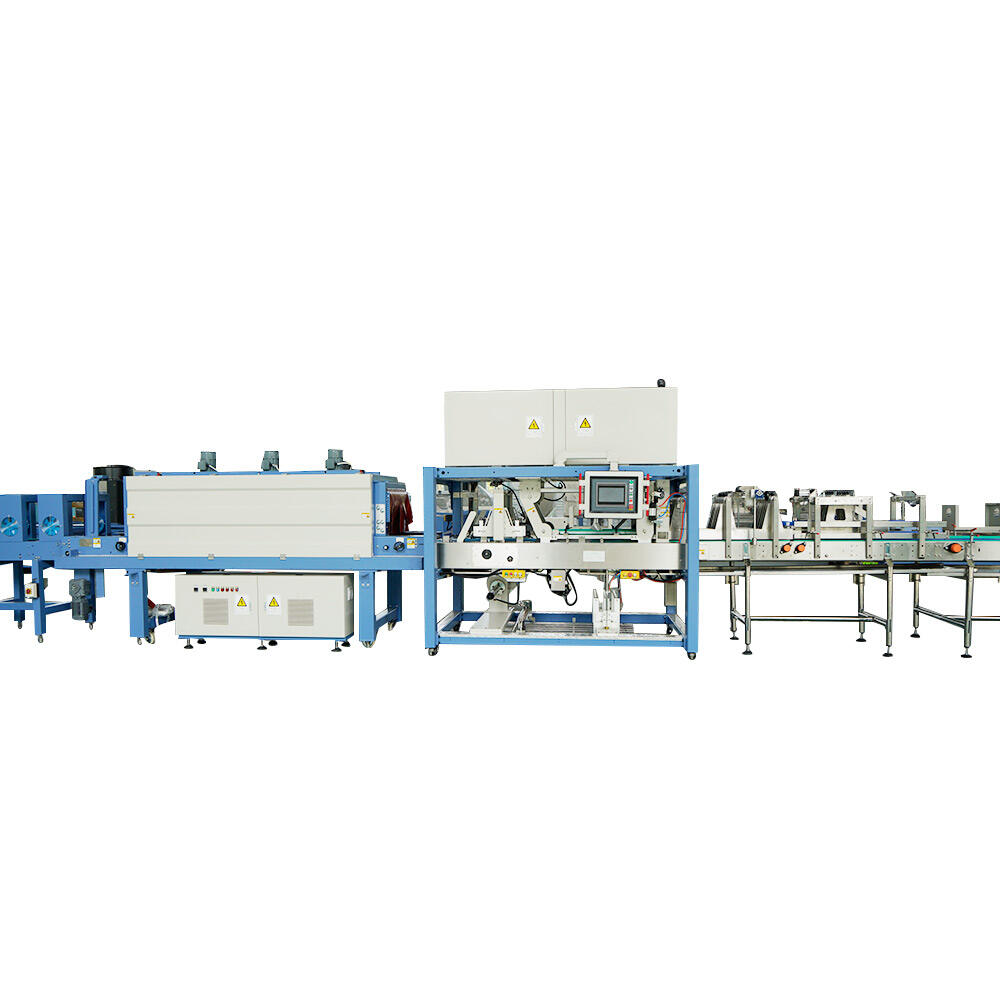

shrink film packer

A shrink film packer represents a crucial piece of automated packaging equipment designed to efficiently wrap products in heat-shrinkable film. This advanced machinery seamlessly integrates cutting-edge technology with practical functionality, enabling businesses to protect, bundle, and present their products professionally. The system operates by automatically measuring and cutting precise lengths of shrink film, wrapping them around products, and applying controlled heat to create a tight, secure seal. The machine's sophisticated control system ensures consistent film tension and temperature management, resulting in uniformly wrapped packages without wrinkles or loose sections. Modern shrink film packers feature adjustable settings to accommodate various product sizes and shapes, making them versatile solutions for diverse packaging needs. These machines excel in high-volume production environments, capable of processing hundreds of units per hour while maintaining precision and quality. The integration of safety features, such as emergency stops and temperature controls, ensures operator protection and product integrity throughout the packaging process. Additionally, these systems often include energy-efficient heating elements and smart controls to optimize power consumption and reduce operational costs.