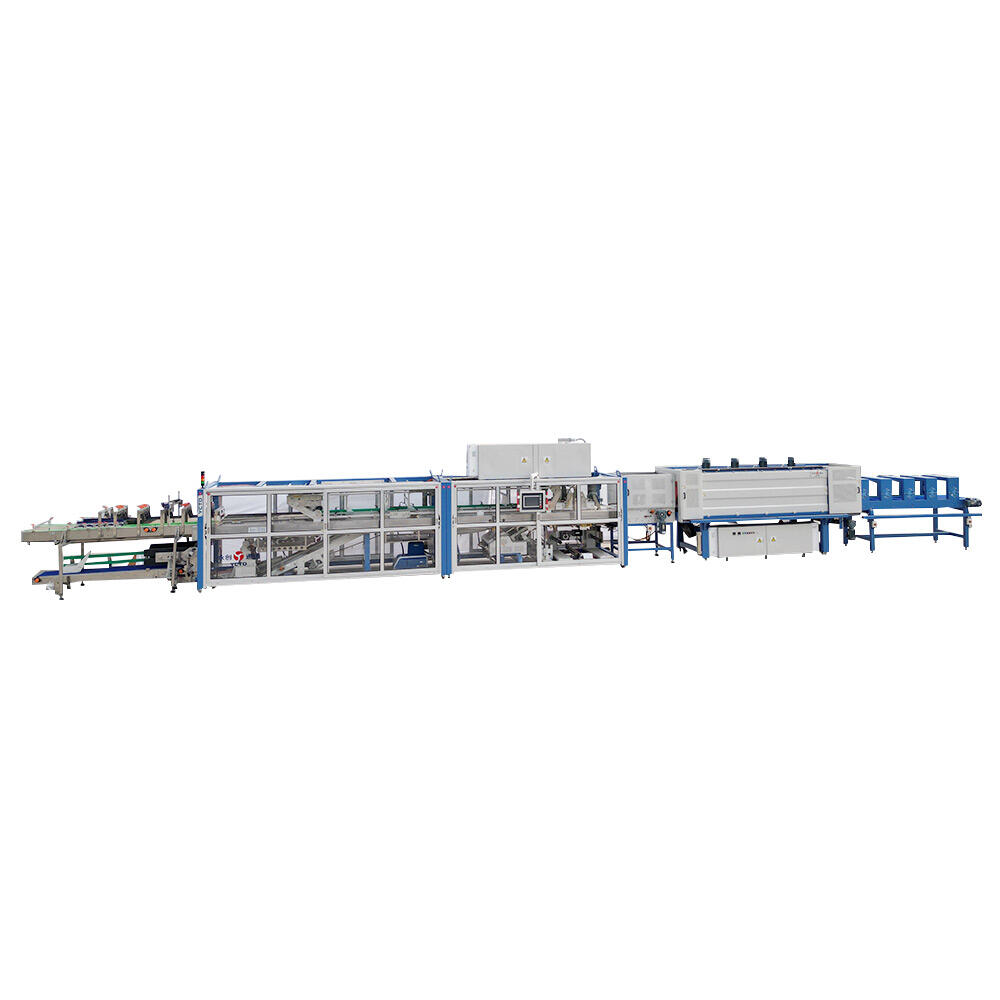

tray shrink wrapping machine

A tray shrink wrapping machine is an advanced packaging solution designed to efficiently wrap products in shrink film while securing them on trays or pads. This automated system combines precision engineering with versatile functionality to meet various packaging needs across industries. The machine operates through a systematic process that includes product placement, film wrapping, and heat shrinking. Initially, products are arranged on trays or pads, then the machine precisely measures and cuts shrink film to size. The wrapping mechanism ensures consistent tension and alignment while encasing the products. The wrapped package then passes through a heat tunnel where controlled temperature causes the film to shrink uniformly, creating a tight, professional finish. Modern tray shrink wrapping machines feature adjustable settings to accommodate different product sizes and shapes, making them suitable for packaging everything from beverages and food items to consumer goods and industrial products. The technology incorporates advanced control systems that maintain precise temperature regulation and conveyor speed, ensuring optimal shrink performance and product protection. These machines are particularly valued in high-volume production environments where consistent packaging quality and operational efficiency are essential.