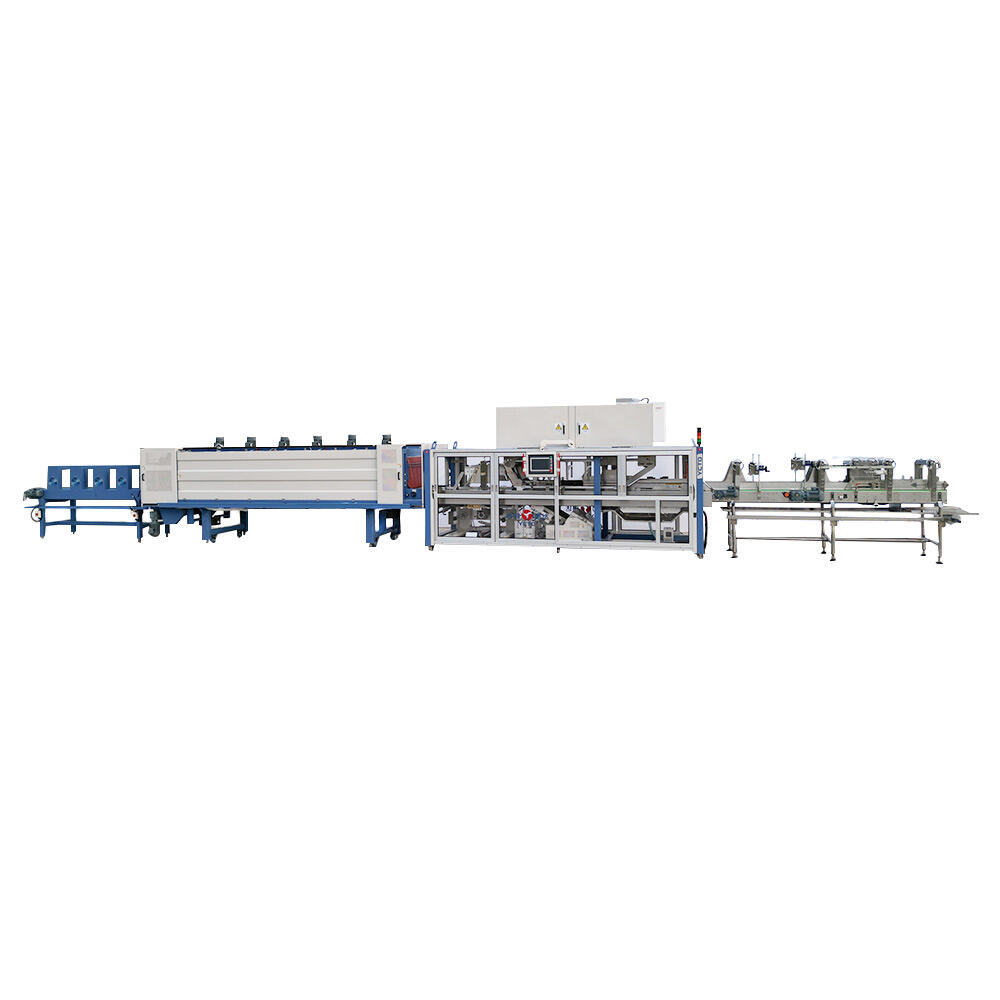

thermal shrink packaging machine

A thermal shrink packaging machine is a sophisticated piece of equipment designed to efficiently wrap and protect products using heat-shrinkable film. This versatile machine operates by enveloping items in specialized plastic film and applying controlled heat, causing the material to shrink tightly around the product. The process begins with precise film measurement and cutting, followed by product wrapping and heat application through a thermal tunnel. The machine's advanced temperature control system ensures consistent shrinkage without product damage. Modern thermal shrink packaging machines feature adjustable conveyor speeds, multiple temperature zones, and digital controls for optimal performance across various product sizes. These machines can handle diverse materials, from single items to bundled products, making them ideal for industries such as food and beverage, cosmetics, pharmaceuticals, and consumer goods. The technology incorporates safety features like emergency stops and cool-down systems, while maintaining energy efficiency through insulated chambers and heat recovery systems. With production speeds ranging from 10 to 30 packages per minute, these machines significantly enhance packaging efficiency while reducing labor costs and material waste.