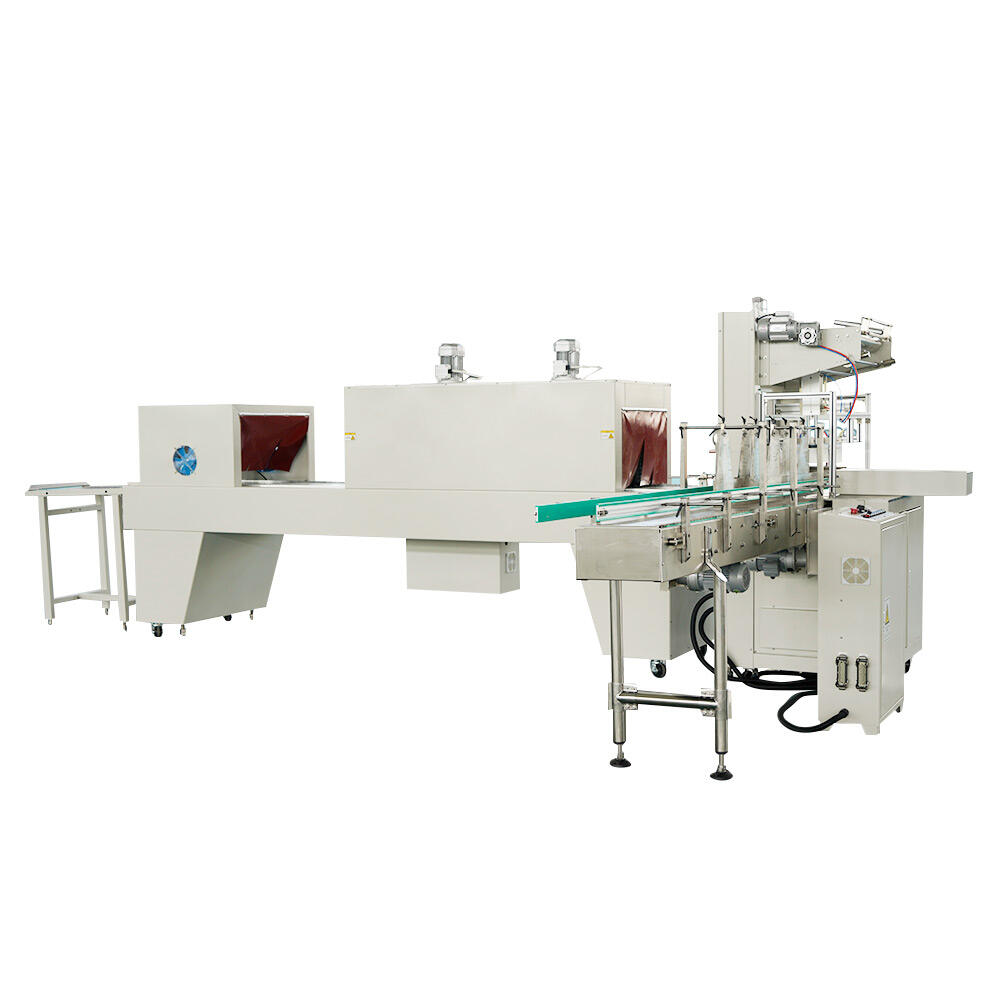

shrink wrap heat sealer

A shrink wrap heat sealer is a versatile packaging solution that combines precision engineering with user-friendly operation to create professional-quality sealed packages. This essential equipment utilizes controlled heat application to create airtight seals on shrink wrap materials, ensuring product protection and presentation excellence. The device features adjustable temperature controls, allowing operators to optimize sealing conditions for different film thicknesses and materials. Modern shrink wrap heat sealers incorporate advanced heating elements that provide consistent temperature distribution, resulting in uniform seals without weak spots or burns. The machine's design typically includes an ergonomic handle, precise timing mechanisms, and safety features to prevent overheating. These sealers can accommodate various package sizes and are commonly equipped with different seal width options, ranging from 2mm to 5mm, to suit diverse packaging requirements. The technology enables both L-sealing and straight-line sealing capabilities, making it suitable for packaging items of varying dimensions. Applications span across multiple industries, from retail and food packaging to industrial and pharmaceutical sectors, where maintaining product integrity and appearance is crucial.