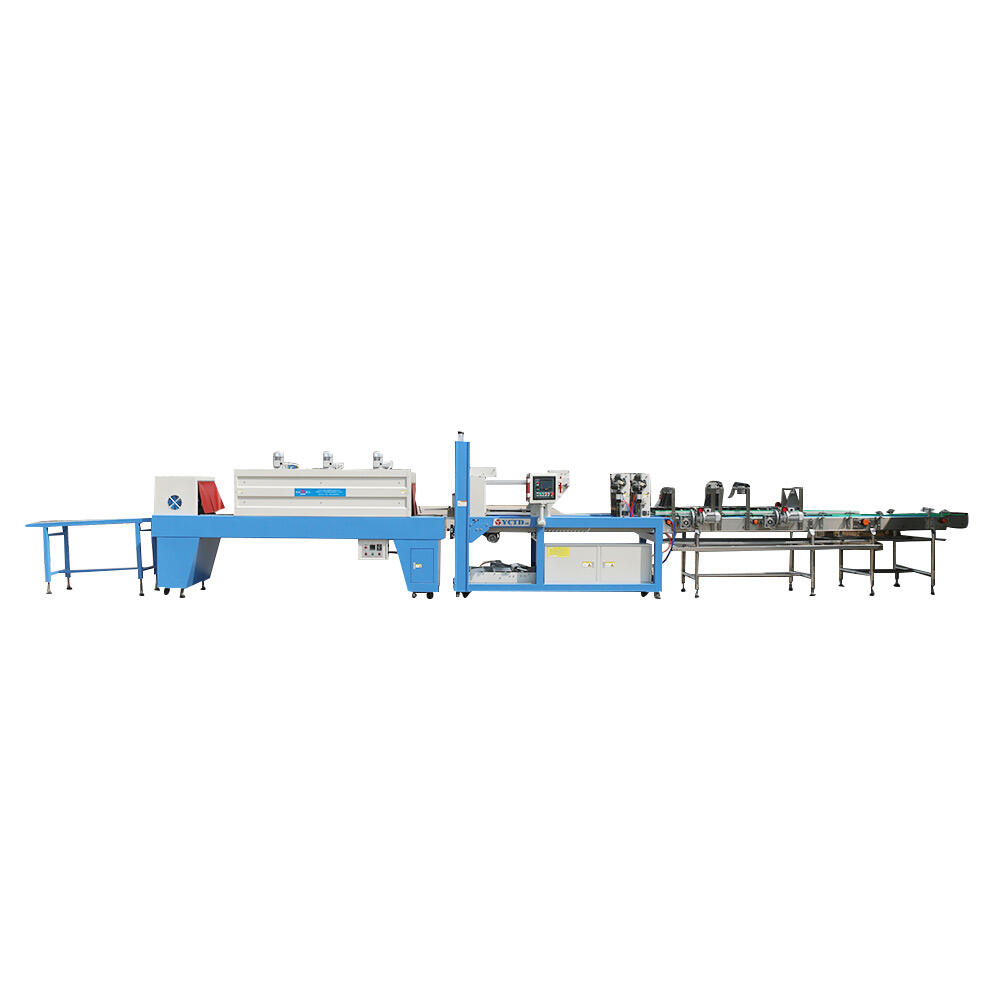

shrink wrap machine heat sealer

The shrink wrap machine heat sealer represents a cutting-edge solution in packaging technology, designed to provide efficient and professional-grade wrapping capabilities for businesses of all sizes. This versatile equipment combines precise temperature control with adjustable sealing mechanisms to create seamless, protective packaging for various products. The machine utilizes advanced heating elements that ensure uniform heat distribution across the sealing surface, resulting in consistent and reliable seals every time. With customizable temperature settings ranging from 100-200°C, it accommodates different types of shrink wrap materials, including PVC, POF, and PE films. The system features an integrated timer control that allows operators to set specific sealing durations, ensuring optimal results while preventing material waste. Modern shrink wrap machine heat sealers come equipped with digital displays for precise monitoring and adjustment of operational parameters. The equipment's robust construction, typically featuring stainless steel components, guarantees durability and long-term reliability in industrial environments. These machines are particularly valuable in industries such as food packaging, retail, pharmaceutical, and manufacturing sectors, where product protection and presentation are paramount.