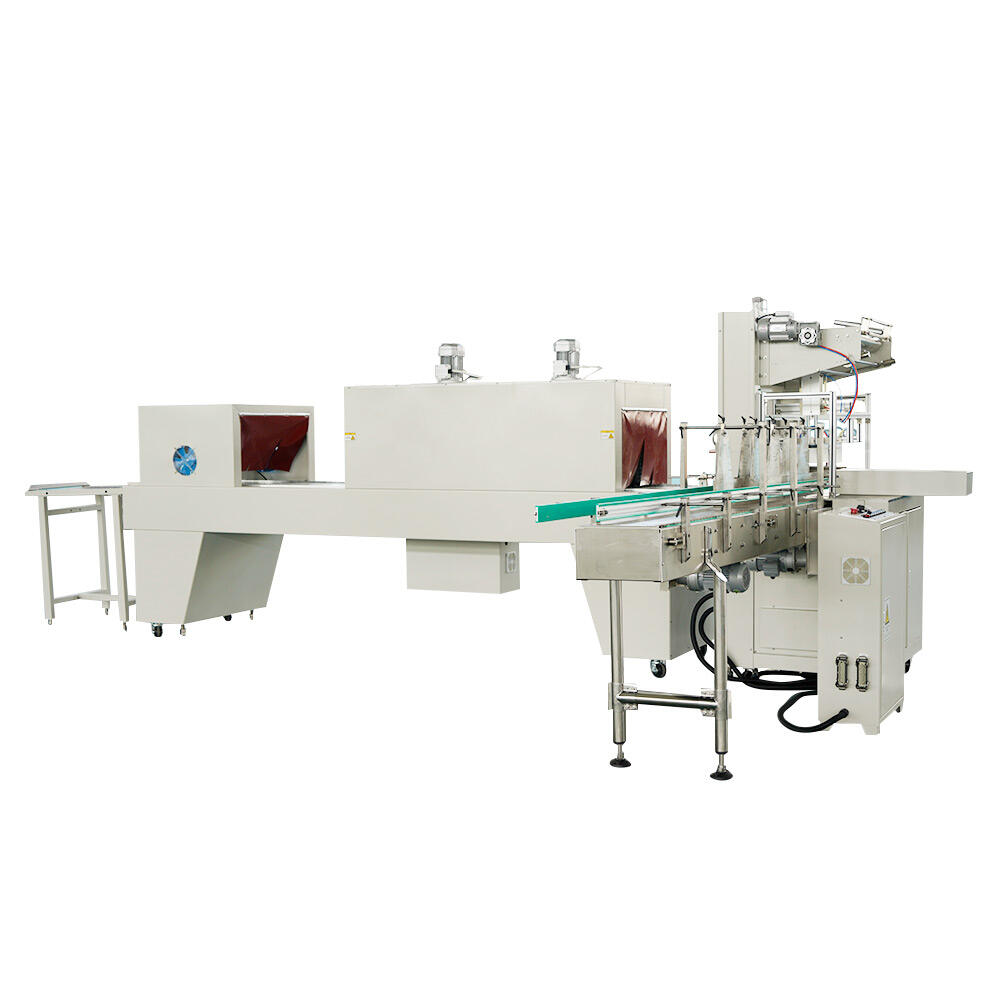

automatic shrink wrapper

An automatic shrink wrapper represents a sophisticated packaging solution that revolutionizes the way products are bundled and protected. This advanced machinery automatically envelops products in shrink film and applies heat to create a tight, secure package. The system typically consists of several key components, including a conveyor belt, film feeding mechanism, sealing bar, and heat tunnel. The process begins as products enter the wrapping zone where precisely measured shrink film is dispensed and cut to size. The wrapper then creates seals around the product, forming a loose sleeve or complete enclosure. As packages move through the heated tunnel, the film contracts uniformly, conforming to the product's shape and creating a professional, retail-ready appearance. Modern automatic shrink wrappers incorporate smart controls that allow operators to adjust temperature, speed, and film tension settings for optimal results across different product sizes and shapes. These machines can handle various product configurations, from single items to multi-packs, and accommodate both regular and irregular shapes. The technology includes safety features such as emergency stops, temperature monitoring, and automated fault detection to ensure consistent operation and protect both operators and products.