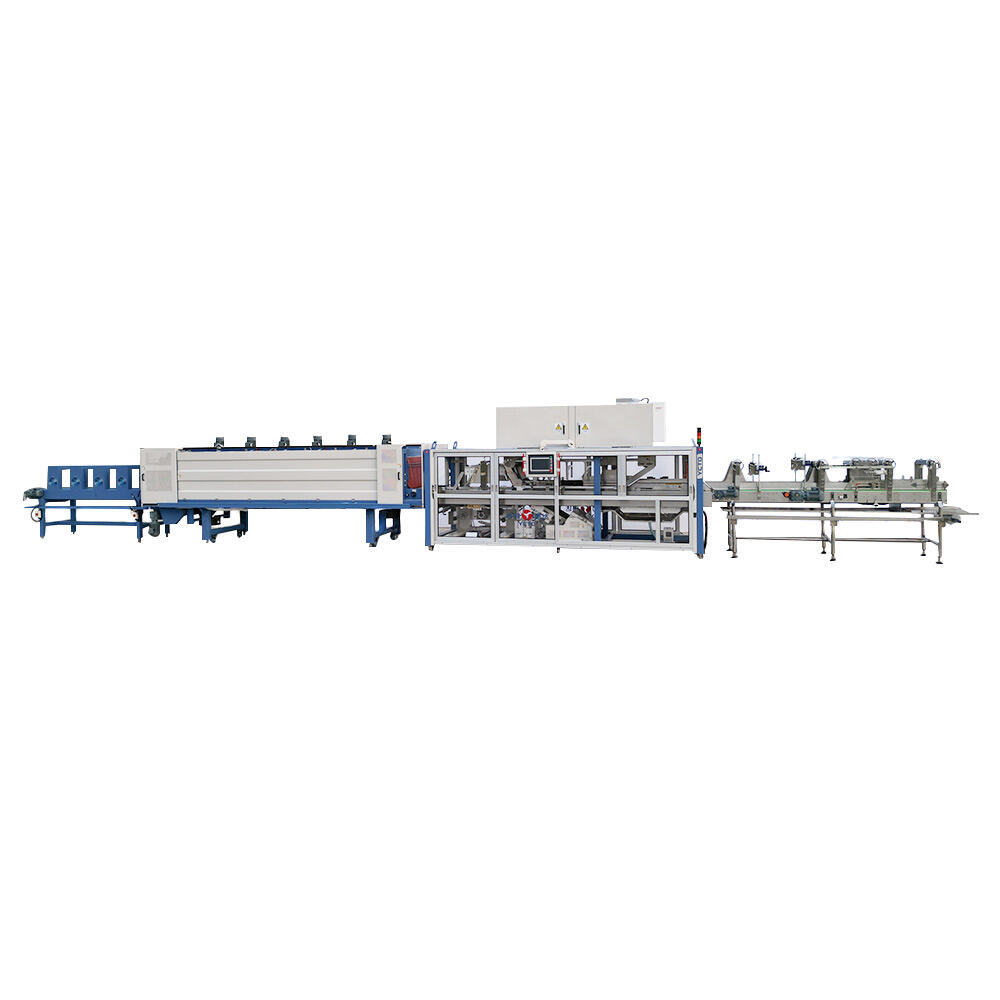

shrink wrap packaging machine

A shrink wrap packaging machine is an advanced automated system designed to efficiently enclose products in protective plastic film that shrinks tightly around items when heat is applied. These versatile machines integrate cutting-edge technology to streamline packaging operations across various industries. The system typically consists of multiple components including a sealing mechanism, a heat tunnel, and a conveyor system that work in harmony to deliver professional packaging results. The machine can handle products of different sizes and shapes, from small individual items to larger bundled products, making it highly adaptable to diverse packaging needs. The process begins with product placement, followed by film wrapping, sealing, and heat shrinking, all executed with precision timing and temperature control. Modern shrink wrap machines incorporate digital controls for accurate temperature regulation, speed adjustment, and operational parameters, ensuring consistent packaging quality. These machines can achieve impressive output rates, with some models capable of processing hundreds of packages per hour. The technology also includes safety features such as emergency stops, overload protection, and thermal regulation systems to protect both operators and products. Advanced models offer additional features like automatic film feeding, precise cutting mechanisms, and programmable settings for different product specifications.