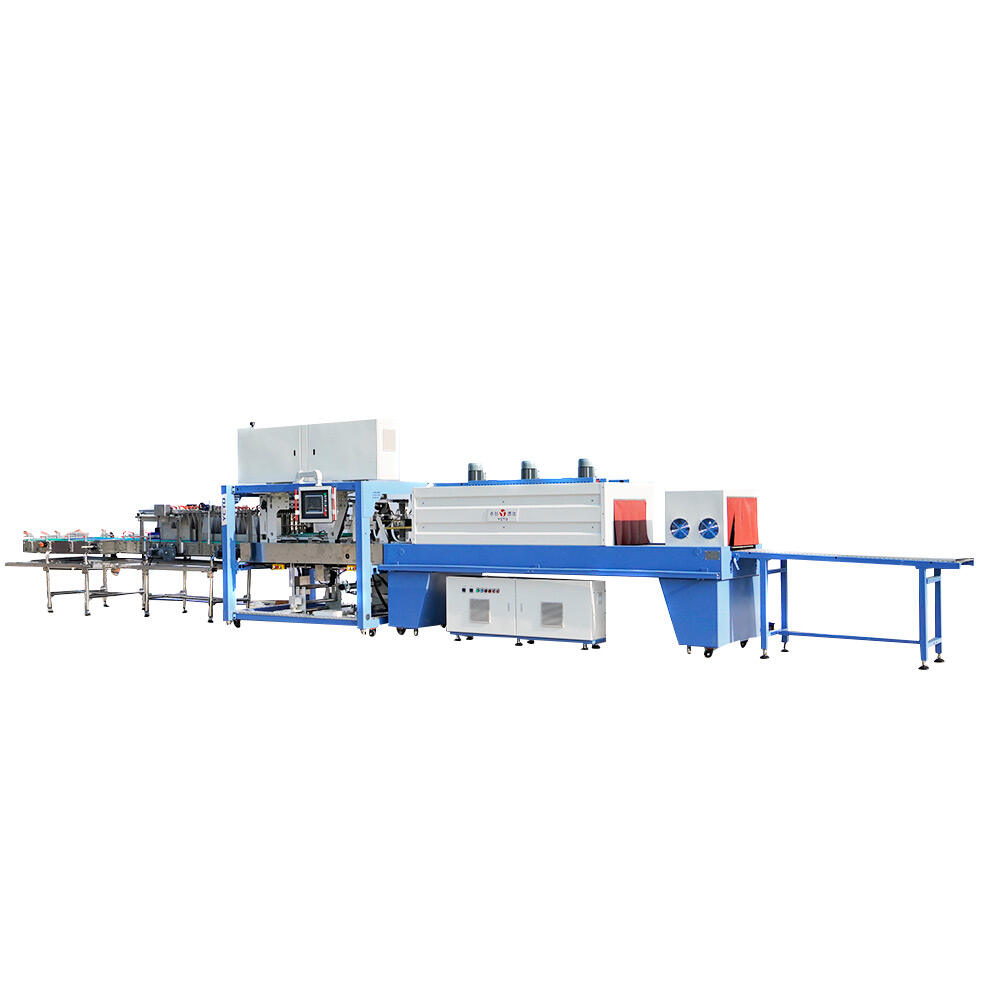

automatic shrink film machine for juice bottles

The automatic shrink film machine for juice bottles represents a cutting-edge solution in beverage packaging automation. This sophisticated equipment streamlines the process of applying shrink film to juice bottles through a synchronized system of conveyor belts, heating elements, and precise control mechanisms. The machine efficiently handles various bottle sizes and shapes, processing them through multiple stages including film feeding, wrapping, and heat shrinking. Its advanced PLC control system ensures consistent operation while maintaining optimal temperature and speed settings. The machine features adjustable conveyor heights, automated film cutting mechanisms, and a thermal tunnel that provides 360-degree uniform heat distribution for perfect shrinkage. With production speeds capable of handling up to 30 packages per minute, this system significantly enhances packaging efficiency while reducing labor costs. The machine's stainless steel construction ensures durability and compliance with food industry standards, while its user-friendly interface allows for easy operation and quick format changes. Safety features include emergency stop buttons, overload protection, and temperature control systems to prevent film burning. The machine's modular design facilitates maintenance and cleaning, ensuring long-term reliable operation in juice bottling facilities.