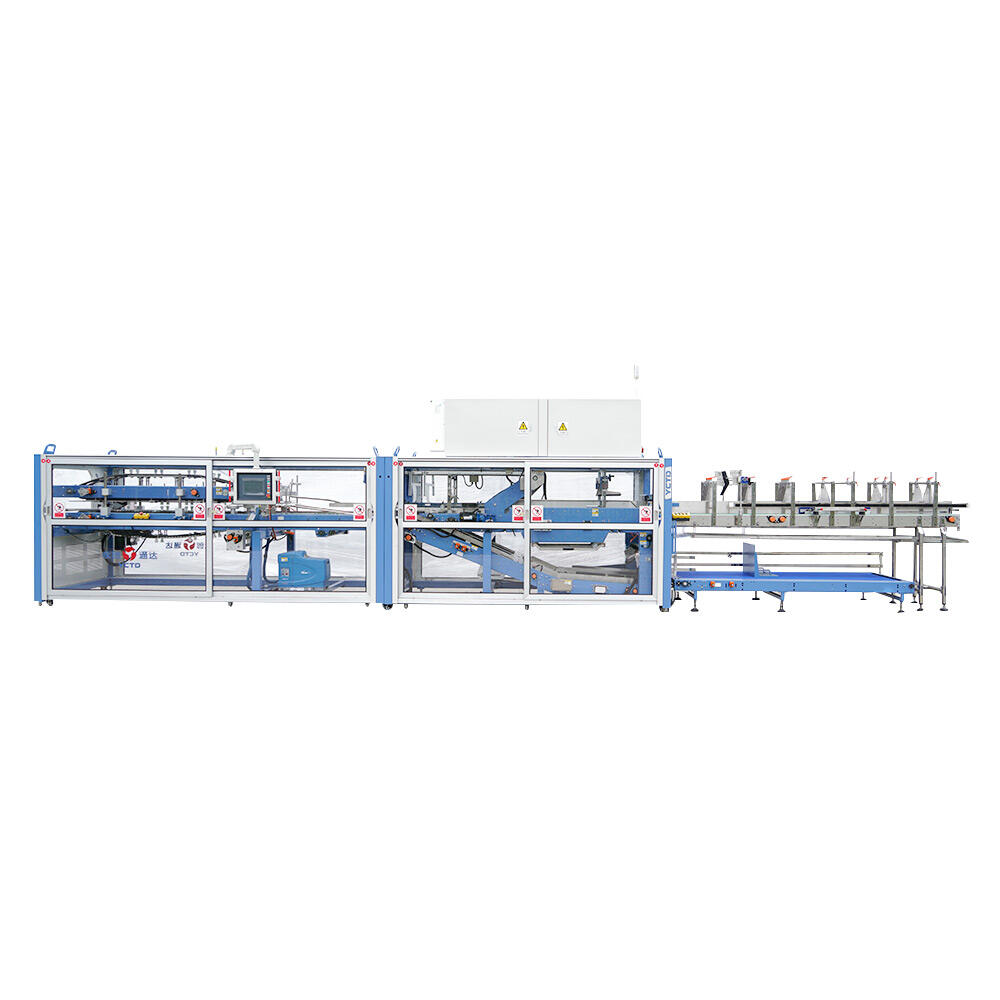

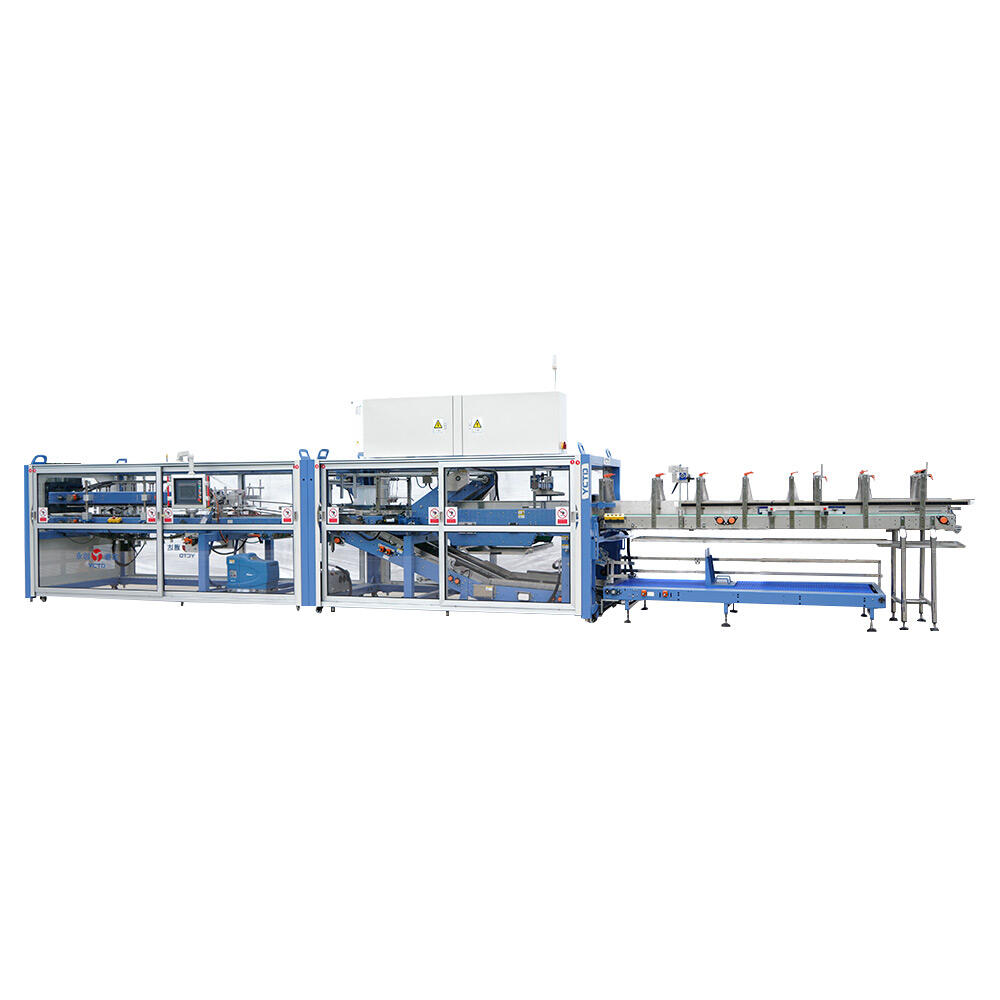

wraparound case packer

The wraparound case packer represents a cutting-edge solution in packaging automation, designed to efficiently bundle and protect products in retail-ready cases. This sophisticated machinery transforms flat cardboard blanks into secure, customized cases around products, operating through a seamless mechanical process. The system begins by selecting and erecting flat cardboard blanks, precisely positioning them for product loading. Using advanced servo-driven technology, it then wraps the cardboard around grouped products with exceptional accuracy. The machine's intelligent control system ensures consistent case formation while maintaining product integrity throughout the process. Essential features include adjustable guide rails for various product sizes, automated glue application systems, and precision folding mechanisms that create tight, square corners. The wraparound case packer excels in handling diverse product types, from beverages and food items to consumer goods and industrial products. Its versatile design accommodates multiple pack patterns and case sizes, making it ideal for high-volume production environments. Modern wraparound case packers incorporate sensors and diagnostic systems that monitor operations in real-time, preventing jams and ensuring optimal performance. This technology proves particularly valuable in industries requiring frequent product changeovers and those demanding high-speed, continuous packaging operations.