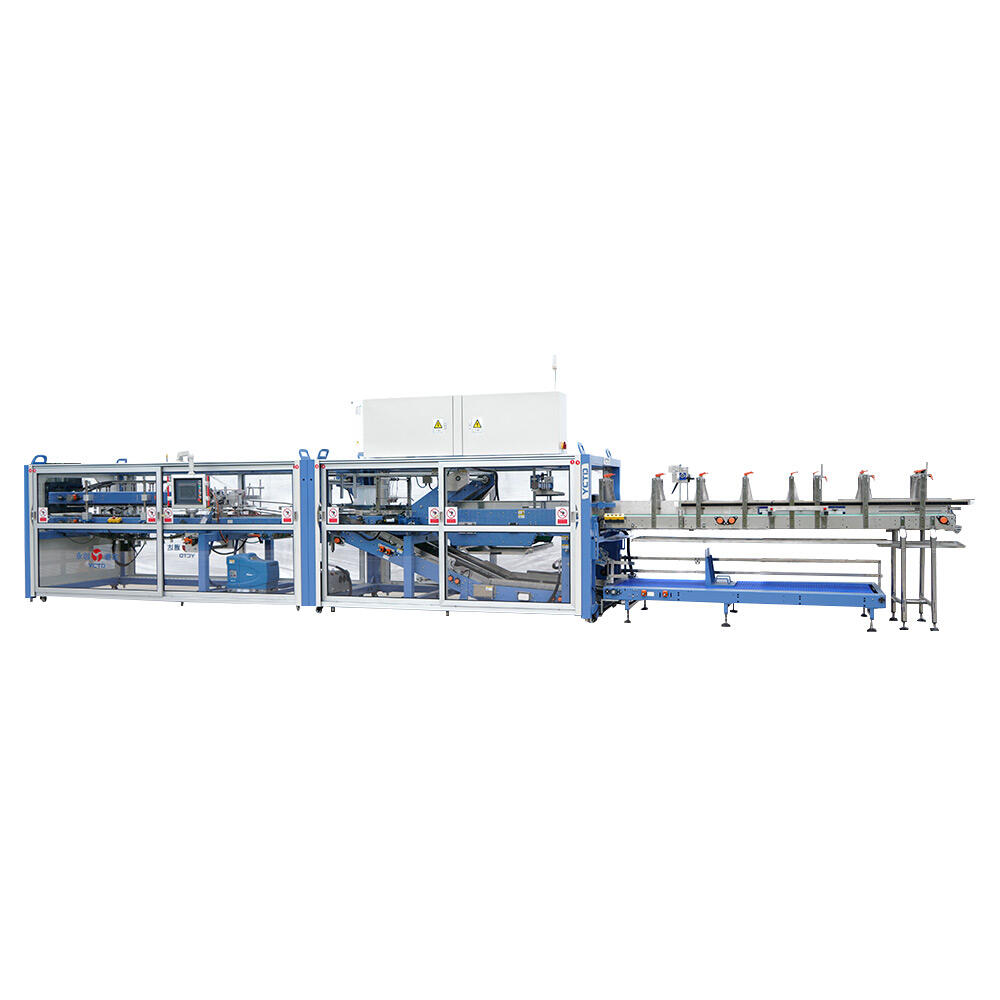

packaging case packer

A packaging case packer is an advanced automated system designed to efficiently pack products into cases, cartons, or containers. This sophisticated machinery streamlines the packaging process by automatically organizing, orienting, and loading products into secondary packaging materials. The system incorporates precision engineering with smart controls to handle various product sizes and packaging configurations. Modern case packers utilize servo-driven technology and programmable logic controllers (PLCs) to ensure accurate product placement and consistent operation. These machines can handle multiple packaging formats, including wrap-around cases, RSC cases, and shelf-ready packaging. The case packer's operational workflow typically includes case erecting, product loading, and case sealing phases, all integrated into a single, efficient system. Advanced models feature quick changeover capabilities, allowing for rapid adaptation to different product sizes and packaging requirements. The technology also includes safety features such as emergency stops, guard doors, and operational indicators to protect operators and maintain workplace safety standards. These systems are particularly valuable in industries such as food and beverage, pharmaceutical, consumer goods, and personal care products, where high-volume packaging efficiency is crucial for operational success.