Transform Your Manufacturing Efficiency with Automated Packaging Solutions

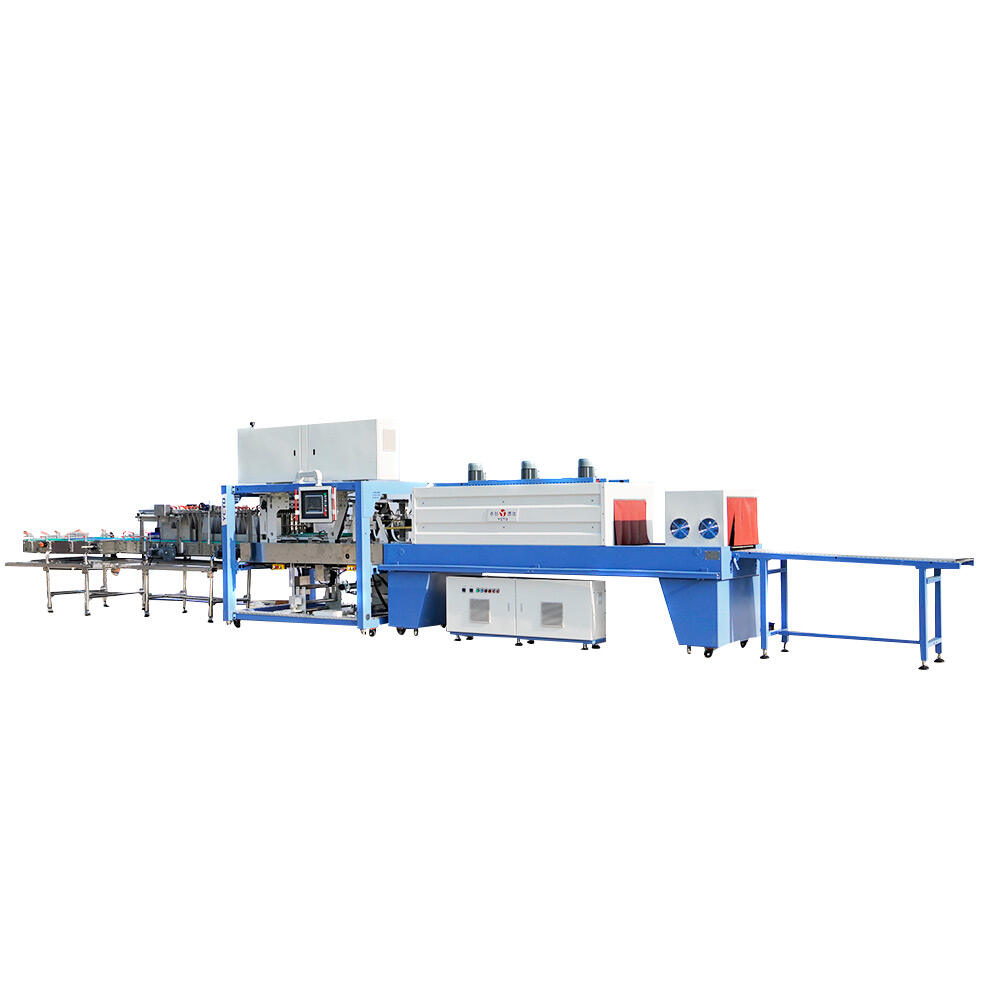

Modern manufacturing facilities are constantly seeking ways to streamline their operations and improve productivity. At the heart of this evolution lies the carton packaging machine, a revolutionary technology that has fundamentally changed how products are prepared for shipment and storage. These sophisticated systems have become indispensable in today's fast-paced manufacturing environment, offering a perfect blend of speed, precision, and reliability.

The integration of a carton packaging machine into manufacturing processes represents a significant leap forward in packaging technology. These machines have proven their worth across various industries, from food and beverage to pharmaceuticals and consumer goods. By automating the packaging process, manufacturers can achieve unprecedented levels of efficiency while maintaining consistent quality standards.

Operational Excellence and Cost Benefits

Enhanced Production Speed and Output

The implementation of a carton packaging machine dramatically increases production capacity compared to manual packaging methods. These automated systems can typically process hundreds of units per minute, maintaining consistent speed without fatigue. This remarkable throughput enables manufacturers to meet growing demand and tight deadlines while maintaining quality standards.

Moreover, the precision and reliability of modern carton packaging machines mean that production lines can operate for extended periods with minimal downtime. This sustained operation translates directly into higher daily output volumes and improved overall equipment effectiveness (OEE).

Significant Labor Cost Reduction

By automating the packaging process, manufacturers can substantially reduce their reliance on manual labor. A single carton packaging machine can often replace several manual packaging stations, leading to significant cost savings in wages, training, and associated human resource management. This automation also helps address the challenges of labor shortages and high turnover rates commonly faced in manufacturing environments.

The reduced labor requirement doesn't just cut direct costs; it also minimizes the risks associated with repetitive motion injuries and worker fatigue, potentially leading to lower insurance premiums and fewer workplace compensation claims.

Quality and Consistency Improvements

Superior Package Integrity

Modern carton packaging machines employ sophisticated control systems and precise mechanisms to ensure each package meets exact specifications. These machines consistently apply the correct pressure and adhesive amounts, resulting in properly sealed packages that protect products during storage and transportation. The precision of automated systems virtually eliminates common manual packaging errors such as misaligned flaps or inadequate sealing.

The enhanced package integrity achieved through automated systems also reduces product damage rates and returns, leading to higher customer satisfaction and lower replacement costs. This consistency is particularly crucial for sensitive or high-value products that require specific packaging parameters.

Standardized Packaging Appearance

Brand presentation plays a crucial role in product marketing, and carton packaging machines excel in maintaining visual consistency. Every package produced follows identical folding patterns and alignment, creating a professional, uniform appearance that enhances brand perception. This standardization is particularly valuable for products displayed in retail environments where packaging aesthetics influence purchasing decisions.

The consistent appearance extends beyond just visual appeal - it also ensures optimal use of storage space and improved stacking stability during transportation, reducing logistics-related damages and costs.

Sustainability and Material Optimization

Reduced Material Waste

Advanced carton packaging machines are designed to minimize material waste through precise cutting and folding operations. These systems can optimize material usage by calculating the most efficient box sizes and configurations for different products. The reduction in waste not only contributes to cost savings but also aligns with growing environmental consciousness among consumers and regulatory requirements.

Many modern machines feature automatic adjustment capabilities that can fine-tune operations in real-time, further reducing material waste during production changeovers and startup phases. This optimization extends to adhesive application, ensuring minimal excess use while maintaining package integrity.

Energy Efficiency and Environmental Impact

Contemporary carton packaging machines incorporate energy-efficient components and smart power management systems. These features help reduce the overall environmental impact of packaging operations while lowering utility costs. The machines' ability to operate continuously at optimal efficiency levels results in better energy utilization compared to manual packaging processes.

Additionally, these machines can often accommodate eco-friendly packaging materials, supporting manufacturers' sustainability initiatives and meeting growing consumer demand for environmentally responsible packaging solutions.

Advanced Integration and Industry 4.0 Compatibility

Smart Manufacturing Integration

Modern carton packaging machines are designed with Industry 4.0 principles in mind, featuring advanced connectivity options and data collection capabilities. These machines can seamlessly integrate with manufacturing execution systems (MES) and enterprise resource planning (ERP) systems, enabling real-time production monitoring and automated inventory management.

The integration capabilities extend to quality control systems, allowing for automated inspection and rejection of non-compliant packages. This connectivity ensures consistent quality while generating valuable data for process optimization and predictive maintenance.

Future-Ready Adaptability

The modular design of contemporary carton packaging machines allows for easy updates and modifications to meet changing production requirements. This adaptability ensures that investments in packaging automation remain valuable as manufacturing needs evolve. Manufacturers can add new features or upgrade existing capabilities without replacing entire systems.

Furthermore, these machines often support remote monitoring and diagnostics, enabling predictive maintenance and rapid technical support response times. This connectivity helps maintain optimal performance and minimize unexpected downtime.

Frequently Asked Questions

What is the typical return on investment for a carton packaging machine?

The ROI for a carton packaging machine typically ranges from 12 to 24 months, depending on production volume and current manual packaging costs. Factors affecting ROI include reduced labor costs, increased production efficiency, and decreased material waste. Many manufacturers report breaking even sooner than expected due to additional benefits like improved quality and reduced product damage.

How difficult is it to train operators for a carton packaging machine?

Modern carton packaging machines feature user-friendly interfaces and intuitive controls, making operator training relatively straightforward. Most manufacturers provide comprehensive training programs, and operators can typically achieve basic proficiency within a few days. Advanced operations and troubleshooting skills may require additional training over several weeks.

What maintenance requirements should be expected for a carton packaging machine?

Regular maintenance for carton packaging machines includes daily cleaning, weekly lubrication checks, and monthly mechanical inspections. Most machines require scheduled preventive maintenance every 3-6 months, depending on usage intensity. Modern machines often include self-diagnostic systems that alert operators to potential issues before they cause downtime.