Modern logistics operations face unprecedented challenges in maintaining efficiency while reducing operational costs and ensuring worker safety. As supply chains become increasingly complex and e-commerce demands continue to surge, warehouses and distribution centers must adopt advanced automation solutions to remain competitive. A palletizer represents one of the most transformative pieces of equipment in contemporary material handling, offering systematic solutions for stacking products onto pallets with precision and consistency. These sophisticated machines have revolutionized how businesses approach packaging and shipping processes, delivering measurable improvements across multiple operational metrics while addressing critical workforce challenges.

Enhanced Operational Efficiency Through Automation

Speed and Throughput Optimization

Automated palletizer systems dramatically increase throughput rates compared to manual palletizing operations. Modern robotic palletizers can handle between 600 to 1,800 cases per hour depending on configuration and product specifications, significantly outperforming manual workers who typically manage 150 to 300 cases hourly. This substantial increase in processing speed enables facilities to meet tight shipping deadlines and accommodate growing order volumes without proportional increases in labor costs. The consistent operational tempo maintained by automated systems ensures predictable output levels that facilitate better production planning and resource allocation strategies.

Furthermore, palletizer technology eliminates bottlenecks commonly associated with manual operations, such as worker fatigue, shift changes, and varying skill levels among personnel. Continuous operation capabilities allow facilities to maintain consistent throughput during extended shifts and peak demand periods. Integration with upstream and downstream equipment creates seamless material flow that optimizes overall line efficiency and reduces dwell times between processing stages.

Consistency in Palletizing Patterns

Precision palletizing ensures uniform load configurations that maximize pallet utilization while maintaining structural integrity during transportation and storage. Advanced palletizer systems utilize sophisticated algorithms to determine optimal stacking patterns based on product dimensions, weight distribution, and stability requirements. This systematic approach eliminates human error variables that can result in poorly constructed loads, reducing the risk of product damage during handling and transit operations.

Consistent palletizing patterns also facilitate more efficient warehouse space utilization and improve forklift handling characteristics. Standardized load configurations enable automated storage and retrieval systems to operate more effectively while reducing the likelihood of load shifting or collapse during mechanical handling. These improvements translate directly into reduced product loss, lower insurance claims, and enhanced customer satisfaction through improved delivery quality.

Significant Cost Reduction Opportunities

Labor Cost Optimization

Implementation of palletizer systems provides substantial labor cost savings through reduced workforce requirements and elimination of overtime expenses associated with manual palletizing operations. While initial capital investment may be significant, return on investment typically occurs within 18 to 36 months depending on operational volume and current labor costs. The ability to operate continuously without breaks, sick leave, or vacation time provides additional economic advantages that compound over the system lifecycle.

Beyond direct labor savings, automated palletizing reduces indirect costs associated with worker compensation claims, training programs, and employee turnover. Manual palletizing involves repetitive lifting and stacking activities that contribute to workplace injuries and associated workers' compensation expenses. Automation eliminates these physical demands while allowing human workers to focus on higher-value tasks that better utilize their cognitive abilities and decision-making skills.

Material Handling Cost Reduction

Efficient palletizer operation reduces material handling costs through optimized pallet utilization and reduced product damage rates. Precise placement algorithms ensure maximum case density while maintaining load stability, resulting in fewer pallets required per shipment and reduced transportation costs. Studies indicate that proper palletizing techniques can improve space utilization by 15 to 25 percent compared to manual methods, translating into substantial savings for high-volume operations.

Additionally, automated systems reduce packaging material waste through consistent application techniques and elimination of human error factors. Precise stretch film application, accurate case positioning, and optimal compression levels minimize material consumption while maintaining package integrity. These efficiencies contribute to lower operational costs and improved environmental sustainability metrics that align with corporate responsibility initiatives.

Improved Workplace Safety Standards

Elimination of Manual Lifting Hazards

Manual palletizing operations expose workers to significant ergonomic risks associated with repetitive lifting, reaching, and twisting motions. These activities contribute to musculoskeletal disorders that represent approximately 33 percent of all workplace injuries according to occupational safety statistics. Palletizer automation eliminates these physical demands, creating safer work environments while reducing injury-related costs and productivity losses.

Ergonomic improvements extend beyond injury prevention to include enhanced worker comfort and job satisfaction. Employees can focus on supervisory tasks, quality control activities, and equipment maintenance responsibilities that are less physically demanding and more intellectually engaging. This transition often results in improved employee retention rates and reduced recruitment costs associated with high-turnover manual positions.

Enhanced Safety Protocol Implementation

Modern palletizer systems incorporate comprehensive safety features including light curtains, emergency stop systems, and access control mechanisms that prevent unauthorized entry into operational areas. These integrated safety systems ensure compliance with occupational safety regulations while providing additional protection for maintenance personnel and operators. Automated safety monitoring capabilities detect potential hazards and implement protective responses faster than human reaction times allow.

Safety system integration with facility-wide monitoring networks enables real-time incident tracking and proactive risk management strategies. Data collection capabilities provide insights into operational patterns that may indicate developing safety concerns, allowing preventive interventions before incidents occur. This comprehensive approach to safety management demonstrates corporate commitment to employee welfare while reducing liability exposure and insurance costs.

Quality Control and Product Integrity

Consistent Handling Standards

Automated palletizer systems maintain consistent product handling techniques that reduce damage rates and improve overall product quality throughout the packaging process. Precise gripper mechanisms and controlled movement patterns minimize impact forces while ensuring secure case positioning. This careful handling approach is particularly beneficial for fragile products, temperature-sensitive items, and premium goods that require special care during processing.

Quality control integration capabilities allow palletizer systems to perform inspection functions during the stacking process, identifying damaged cases or incorrect products before they reach shipping areas. Vision systems and weight verification mechanisms ensure that only compliant products proceed through the palletizing operation, reducing customer complaints and return processing costs. These quality assurance features contribute to enhanced brand reputation and customer satisfaction metrics.

Traceability and Documentation

Advanced palletizer systems provide comprehensive data logging capabilities that support product traceability requirements and quality management initiatives. Real-time monitoring of palletizing parameters including case counts, pattern configurations, and processing times creates detailed records for regulatory compliance and continuous improvement programs. This documentation capability is particularly valuable for food and pharmaceutical applications where traceability requirements are stringent.

Integration with enterprise resource planning systems enables seamless data transfer that supports inventory management, shipping documentation, and customer service functions. Automated record-keeping eliminates manual documentation errors while providing accurate information for billing, inventory tracking, and quality audits. These capabilities enhance operational transparency and support data-driven decision making processes throughout the organization.

Scalability and Future-Proofing Benefits

Adaptability to Changing Requirements

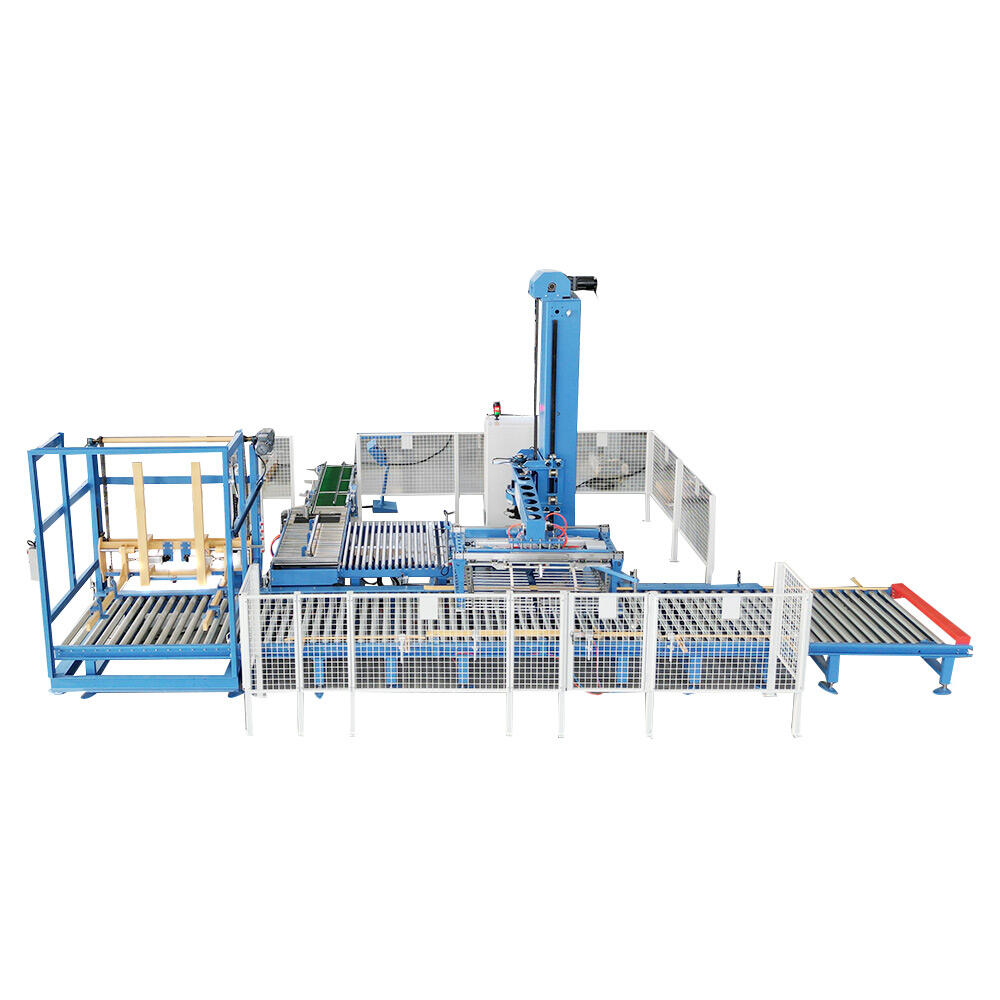

Modern palletizer designs offer modular configurations that accommodate changing product mixes and operational requirements without extensive equipment modifications. Flexible gripper systems, adjustable conveyor components, and programmable control interfaces enable rapid changeovers between different products and palletizing patterns. This adaptability ensures that initial equipment investments remain viable as business needs evolve and product portfolios expand.

Software-based configuration management allows operators to store multiple palletizing programs and switch between them as production schedules require. Remote monitoring and adjustment capabilities enable real-time optimization without interrupting operations, maximizing equipment utilization while maintaining production flexibility. These features support lean manufacturing principles and just-in-time production strategies that require responsive equipment capabilities.

Integration with Smart Manufacturing Systems

Palletizer technology readily integrates with Industry 4.0 manufacturing systems, providing connectivity options that support data analytics, predictive maintenance, and automated optimization functions. Internet of Things sensors and communication protocols enable remote monitoring, performance analysis, and proactive maintenance scheduling that minimize downtime risks. These capabilities align with digital transformation initiatives while providing operational insights that drive continuous improvement efforts.

Machine learning algorithms can analyze operational data to identify optimization opportunities and predict maintenance requirements before equipment failures occur. This predictive approach reduces unplanned downtime costs while extending equipment lifecycles through optimized maintenance scheduling. Advanced analytics capabilities also support energy efficiency initiatives by identifying operational parameters that minimize power consumption without compromising performance standards.

FAQ

What is the typical return on investment period for palletizer equipment

Most palletizer installations achieve return on investment within 18 to 36 months, depending on operational volume, current labor costs, and specific application requirements. High-volume operations with expensive manual labor typically see faster payback periods, while smaller facilities may require longer investment recovery timeframes. Comprehensive cost analysis should include direct labor savings, reduced injury costs, improved efficiency, and quality improvements to accurately calculate total economic benefits.

How much space does a palletizer system require for installation

Space requirements vary significantly based on palletizer type and configuration, but typical installations require 400 to 800 square feet including conveyor systems, safety barriers, and maintenance access areas. Robotic palletizers generally require less floor space than conventional layer-forming systems, making them suitable for facilities with space constraints. Professional site surveys can determine specific space requirements based on product specifications and integration requirements with existing equipment.

What maintenance is required to keep palletizer systems operating efficiently

Routine maintenance includes daily cleaning, weekly lubrication, monthly safety system inspections, and quarterly comprehensive service procedures. Most manufacturers recommend annual professional service visits for major component inspection and calibration. Predictive maintenance programs using sensor data can optimize maintenance schedules while reducing the likelihood of unexpected breakdowns. Proper maintenance typically costs 3 to 5 percent of initial equipment investment annually but significantly extends system lifecycle and maintains optimal performance levels.

Can existing production lines be retrofitted with palletizer technology

Most existing production lines can accommodate palletizer integration with appropriate planning and modification work. Retrofit installations may require conveyor adjustments, electrical upgrades, and safety system enhancements to support automated equipment. Professional engineering assessment can determine retrofit feasibility and identify necessary modifications. While retrofit projects may involve higher installation costs compared to new construction, they typically provide excellent returns through improved efficiency and reduced labor requirements in existing facilities.