shrink wrap commercial

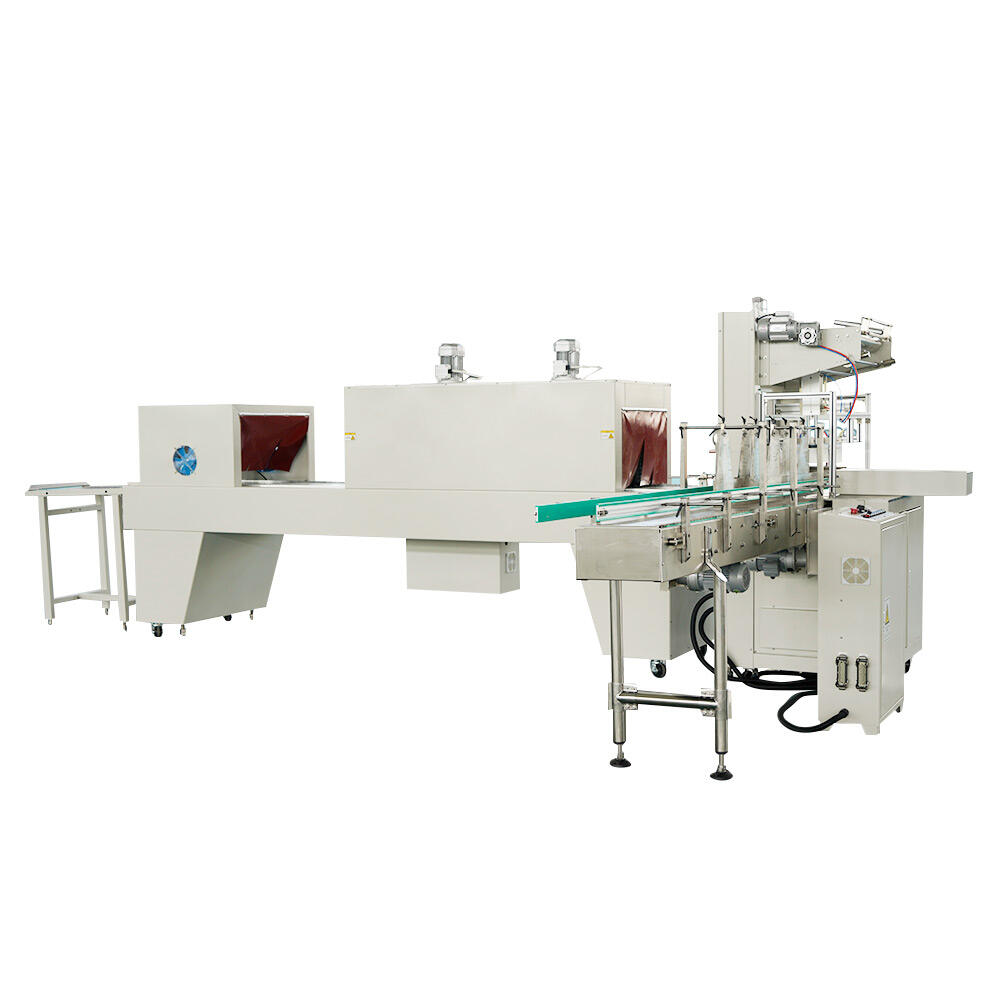

Shrink wrap commercial equipment represents a cutting-edge solution in modern packaging technology, offering businesses a versatile and efficient method for protecting and presenting their products. This advanced packaging system utilizes heat-activated polymer films that conform tightly to items of various shapes and sizes, creating a secure, professional-looking seal. The technology employs precision-controlled heating elements and automated conveyor systems to ensure consistent wrapping results. Modern commercial shrink wrap machines feature adjustable temperature controls, variable speed settings, and multiple sealing options to accommodate different product requirements. These systems can handle both individual items and bundled products, making them invaluable for retail packaging, industrial shipping, and product distribution. The equipment typically includes thermal tunnels, sealing bars, and advanced control panels that allow operators to fine-tune the wrapping process. Safety features such as emergency shut-offs, cool-down cycles, and thermal protection are integrated into the design. The versatility of commercial shrink wrap systems extends to their ability to work with various film types, including polyolefin, PVC, and polyethylene, each offering specific benefits for different applications.