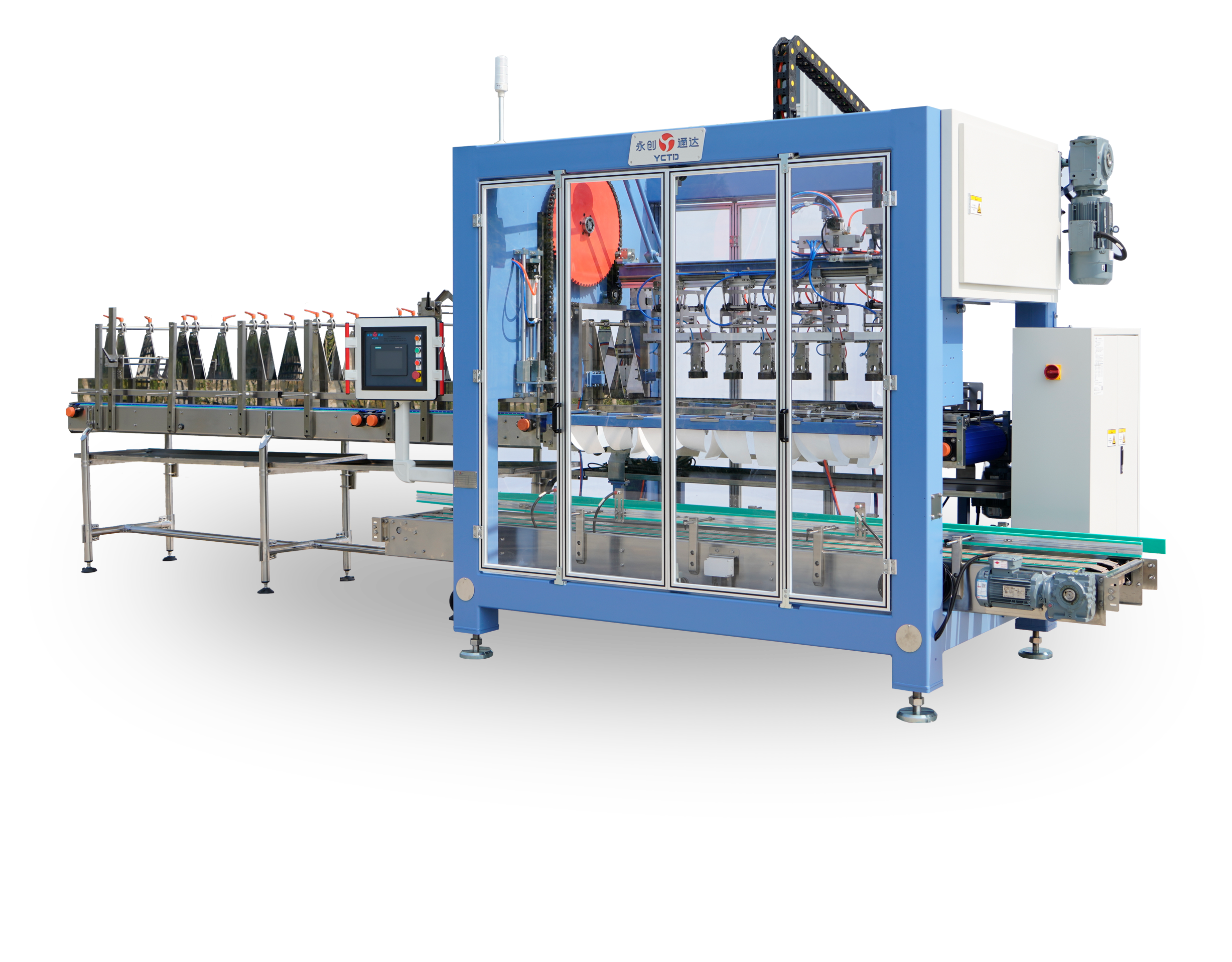

bottle carton packaging machine

The bottle carton packaging machine represents a cutting-edge solution in automated packaging technology, designed to efficiently handle the complex process of packaging bottles into cartons. This sophisticated equipment combines precision engineering with advanced automation to deliver a seamless packaging operation. The machine's primary functions include carton forming, bottle insertion, and final sealing, all executed through a synchronized mechanical system. Operating at speeds of up to 120 cartons per minute, it features an intelligent control system that ensures accurate placement and consistent packaging quality. The machine accommodates various bottle sizes and carton configurations, making it versatile for different product lines. Its advanced sensing technology monitors the entire packaging process, detecting any anomalies and automatically adjusting operations to maintain optimal performance. The system includes automated carton feeding, precise bottle placement mechanisms, and reliable sealing systems, all working in harmony to deliver professional packaging results. This machinery finds extensive applications in beverage industries, pharmaceutical companies, and consumer goods manufacturing, where high-volume, precise packaging is essential.