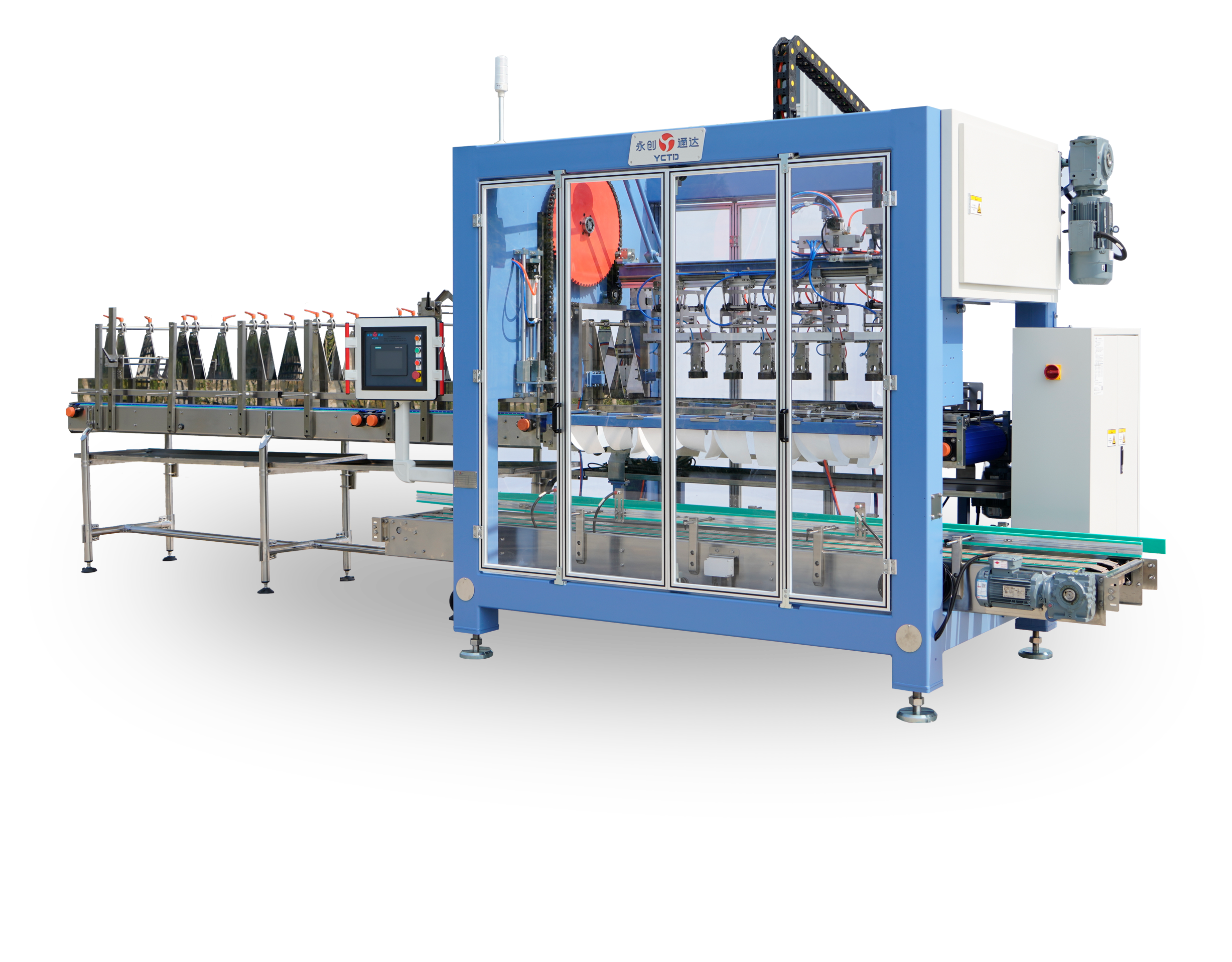

lined carton packing machine

The lined carton packing machine represents a sophisticated solution for efficient packaging operations in modern manufacturing environments. This advanced equipment automates the process of assembling, lining, and sealing cartons with precision and reliability. The machine features a synchronized system that first forms the carton, carefully places a protective liner or bag inside, and then proceeds to fill the lined carton with products. Operating at speeds of up to 20 cartons per minute, it incorporates servo-driven mechanisms for accurate positioning and consistent performance. The machine's versatility allows it to handle various carton sizes and liner materials, making it suitable for diverse industries including food processing, pharmaceuticals, and chemical products. Its intelligent control system enables real-time monitoring and adjustment of operational parameters, ensuring optimal performance and minimal downtime. The integration of safety features, including emergency stop functions and guard doors with interlocks, provides comprehensive operator protection. Additionally, the machine's modular design facilitates easy maintenance and quick format changes, maximizing operational efficiency and reducing production interruptions.