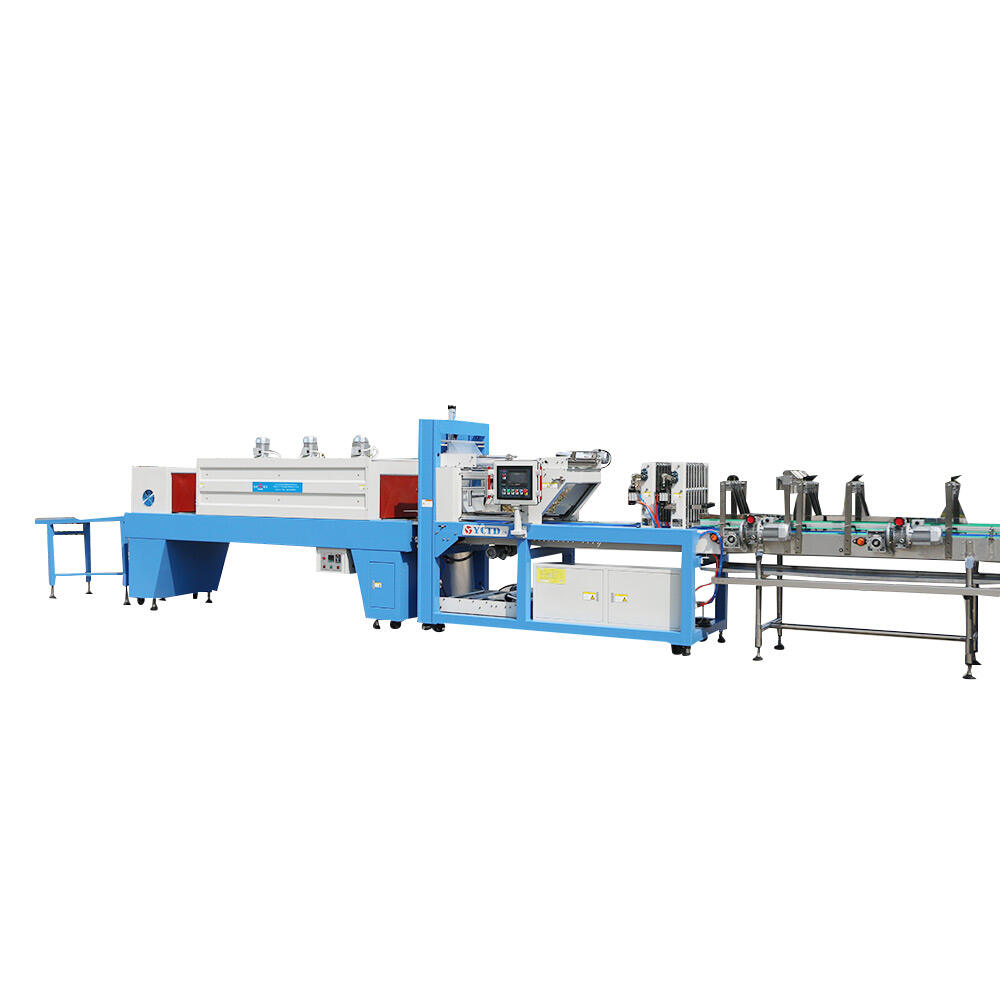

bottle shrink packing machine price

The bottle shrink packing machine price represents a significant consideration for businesses looking to optimize their packaging operations. These machines, available across various price points from $8,000 to $50,000, offer comprehensive solutions for efficient bottle packaging. The price variation depends on factors such as production capacity, automation level, and additional features. Entry-level machines typically handle 10-20 bottles per minute, while industrial-grade systems can process up to 100 bottles per minute. The technology incorporates advanced PLC control systems, precise temperature regulation, and adjustable shrink tunnel parameters. Modern machines feature user-friendly touch screen interfaces, multiple packaging format capabilities, and energy-efficient heating systems. They accommodate various bottle sizes and shapes, making them versatile for different industries including beverage, pharmaceutical, and chemical sectors. The investment considers long-term operational costs, maintenance requirements, and potential return on investment through increased productivity and reduced labor costs.