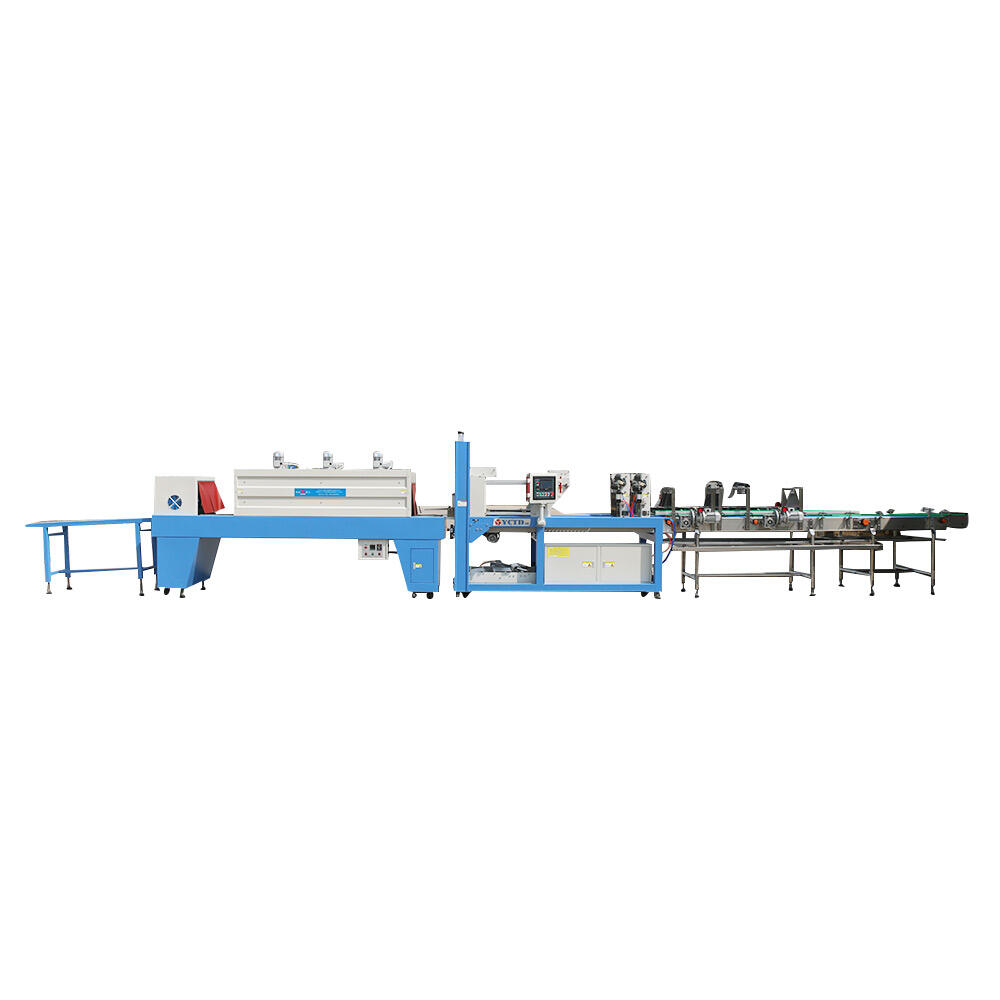

shrink bundling machine

A shrink bundling machine is an advanced packaging solution that efficiently wraps and bundles products using heat-shrinkable film. This versatile equipment operates by creating a tight, secure package around single or multiple items through a controlled heating process. The machine first envelops products in shrink film, then passes them through a heat tunnel where the film contracts uniformly to create a snug, protective covering. Modern shrink bundling machines incorporate precision temperature controls, adjustable conveyor speeds, and automated feeding systems to ensure consistent packaging quality. These machines can handle various product sizes and shapes, making them ideal for industries ranging from beverage and food packaging to consumer goods and industrial products. The system typically includes multiple components: a product infeed section, film wrapping mechanism, sealing station, and heat tunnel. Advanced models feature touch-screen interfaces for easy operation, multiple packaging format options, and energy-efficient heating systems. The technology allows for both single-lane and multi-lane configurations, enabling businesses to scale their packaging operations according to production demands. Safety features such as emergency stops, temperature monitoring, and automatic shut-off systems ensure reliable and secure operation. These machines can achieve impressive throughput rates while maintaining packaging quality and consistency, making them an essential tool for modern manufacturing and distribution operations.