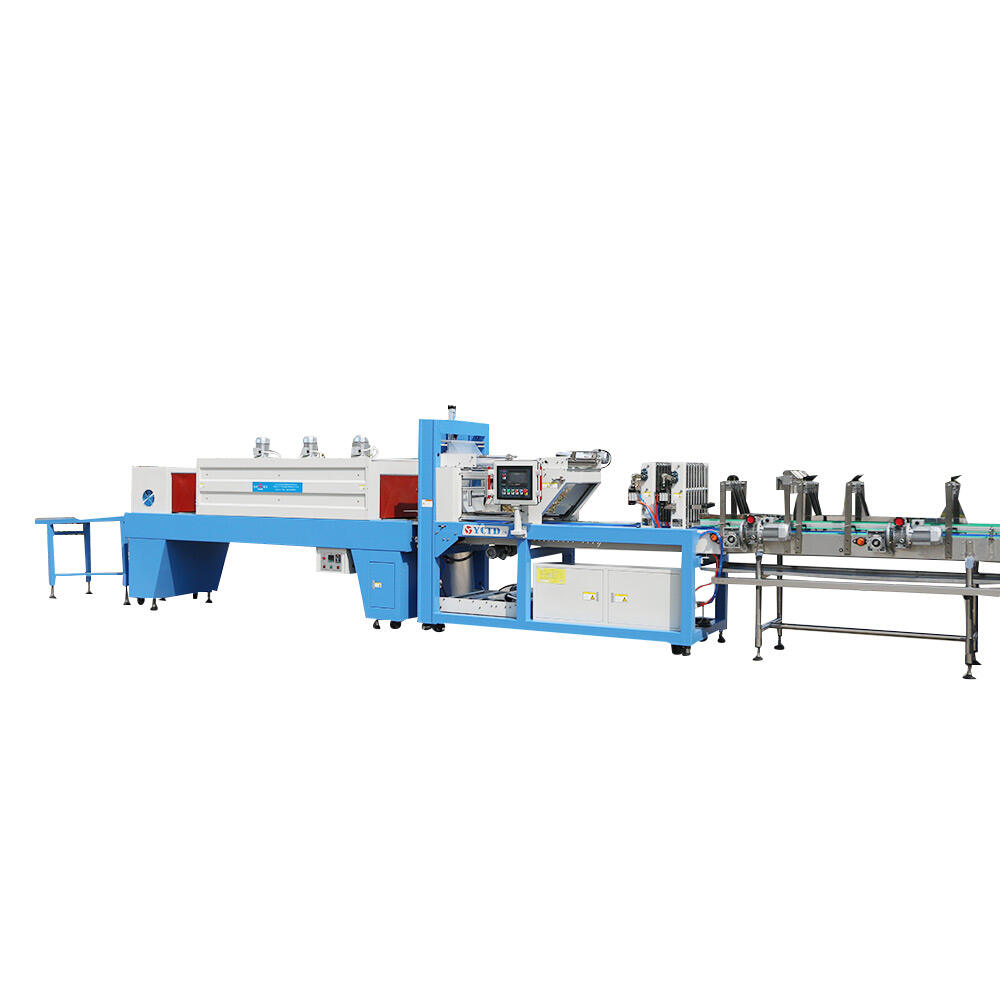

shrink wrapping machine manufacturers

Shrink wrapping machine manufacturers are leading innovators in the packaging industry, specializing in the development and production of advanced packaging solutions. These manufacturers create sophisticated equipment that efficiently wraps products in heat-shrinkable film, providing secure and professional packaging for various industries. Their machines incorporate cutting-edge technology, including precise temperature control systems, adjustable sealing mechanisms, and automated conveyor systems. Modern shrink wrapping machines feature digital controls, enabling operators to fine-tune settings for different product sizes and film types. These manufacturers focus on creating versatile equipment capable of handling diverse packaging needs, from individual items to bulk packaging requirements. The machines are designed with efficiency in mind, offering high-speed operation while maintaining consistent wrapping quality. Safety features are integrated into every aspect, including emergency stop buttons and thermal protection systems. Many manufacturers also provide customization options, allowing businesses to adapt the equipment to their specific packaging requirements. The machines are built with industrial-grade materials, ensuring durability and long-term reliability in demanding production environments. Additionally, these manufacturers often offer comprehensive after-sales support, including maintenance services and technical assistance.