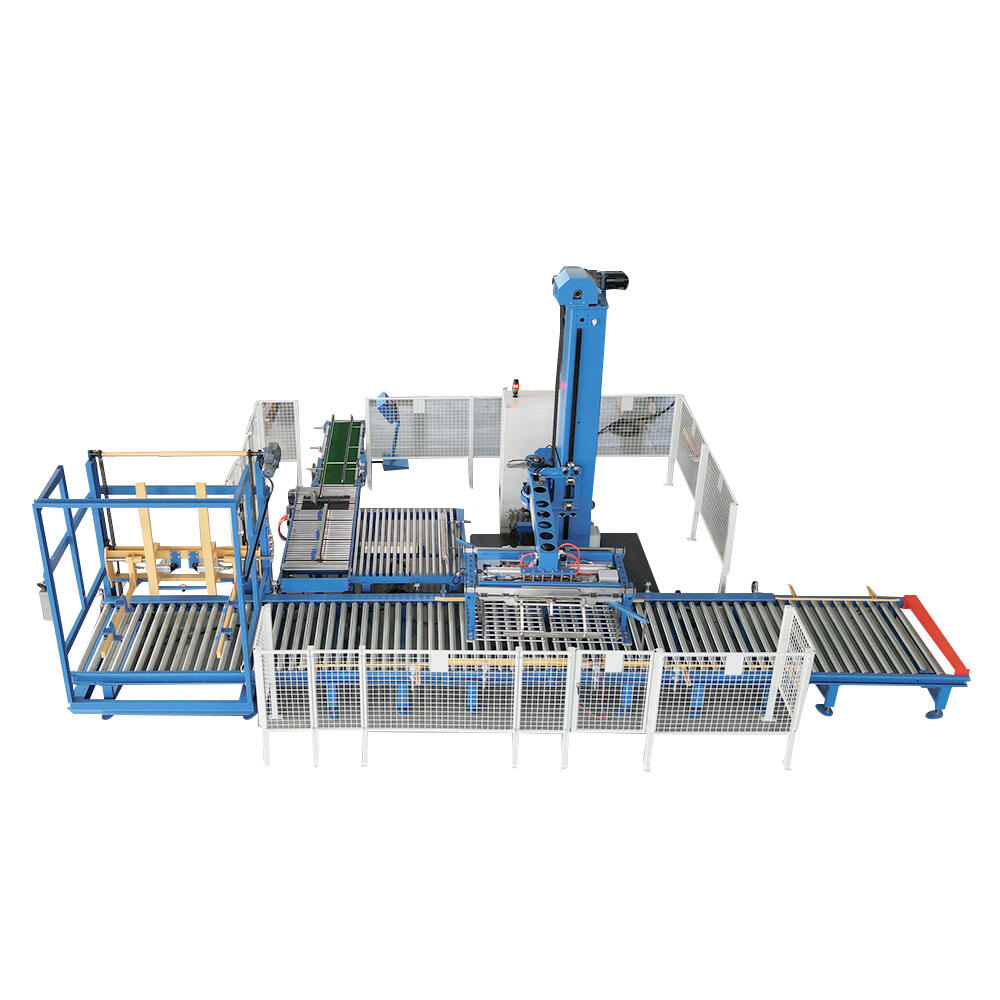

box palletizer machine

A box palletizer machine is an advanced automated solution designed to efficiently stack and organize boxes or cases onto pallets in a systematic manner. This sophisticated equipment combines mechanical precision with smart programming to handle various box sizes and stacking patterns. The machine typically consists of a conveyor system for incoming boxes, a pattern formation area, and a palletizing zone where boxes are precisely positioned according to predetermined patterns. Modern box palletizers incorporate sensors and control systems that ensure accurate placement while maintaining high throughput rates of up to 200 boxes per minute. The technology features adaptive handling capabilities that can manage different product sizes and weights, making it versatile for various industries. These machines often include safety features such as emergency stops, light curtains, and enclosed operating areas to protect workers. Advanced models may also feature automatic pallet dispensers, slip sheet inserters, and integrated wrapping systems for complete end of line automation. The machine's programming allows for multiple stacking patterns and can be easily adjusted through a user friendly interface, enabling quick changeovers between different product runs.