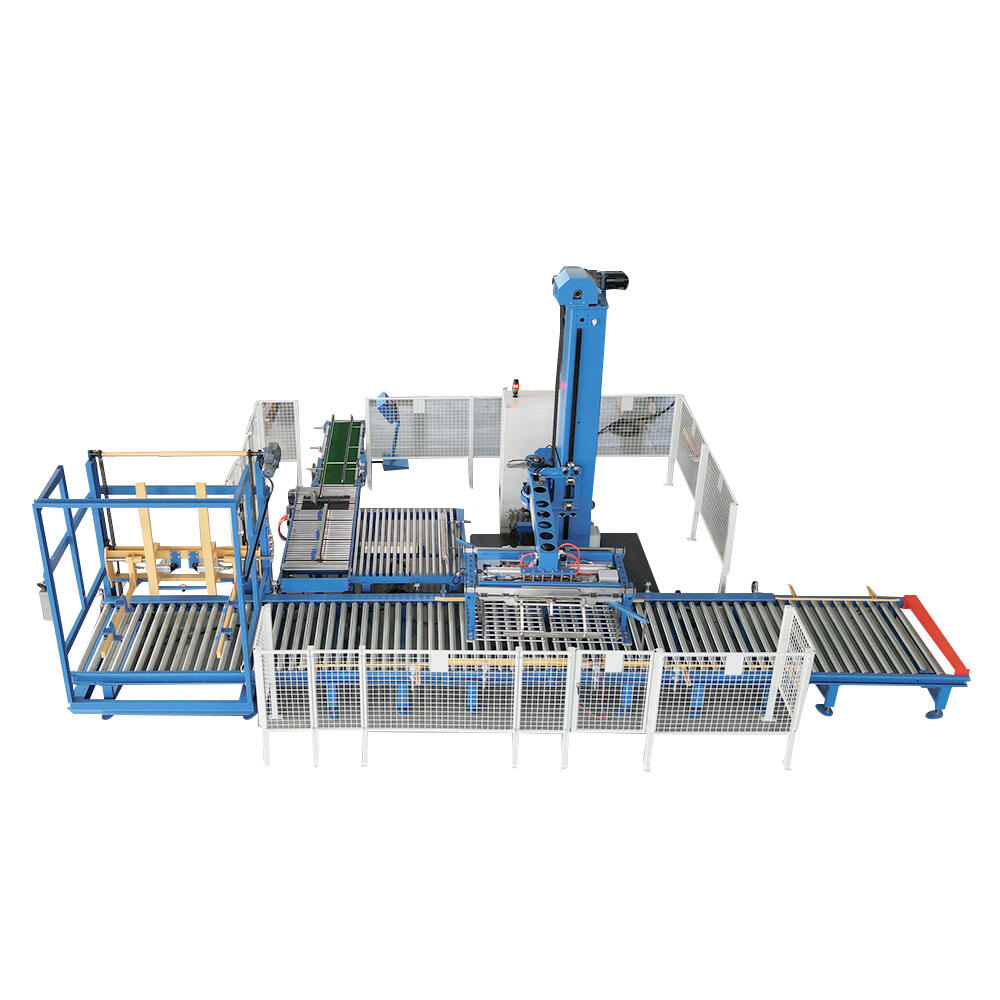

palletizer and depalletizer

A palletizer and depalletizer system represents advanced material handling technology designed to automate the stacking and unstacking of products on pallets. The palletizer efficiently arranges and stacks products, cases, or containers onto pallets in a precise, programmed pattern, while the depalletizer performs the reverse operation by systematically removing items from pallets. These systems utilize sophisticated sensors, robotics, and conveyor systems to handle various product sizes and weights with exceptional accuracy. Modern palletizer and depalletizer solutions incorporate advanced features such as pattern recognition technology, automatic layer formation, and intelligent control systems that can adjust to different product specifications. They operate through a combination of mechanical and electronic components, including servo motors, pneumatic systems, and programmable logic controllers (PLCs) that ensure smooth, consistent operation. These systems find extensive applications across various industries, including food and beverage, pharmaceuticals, consumer goods, and manufacturing, where they significantly enhance operational efficiency and reduce manual labor requirements. The technology can handle multiple product types and pallet configurations, offering flexibility in production environments while maintaining strict safety standards and product integrity throughout the process.