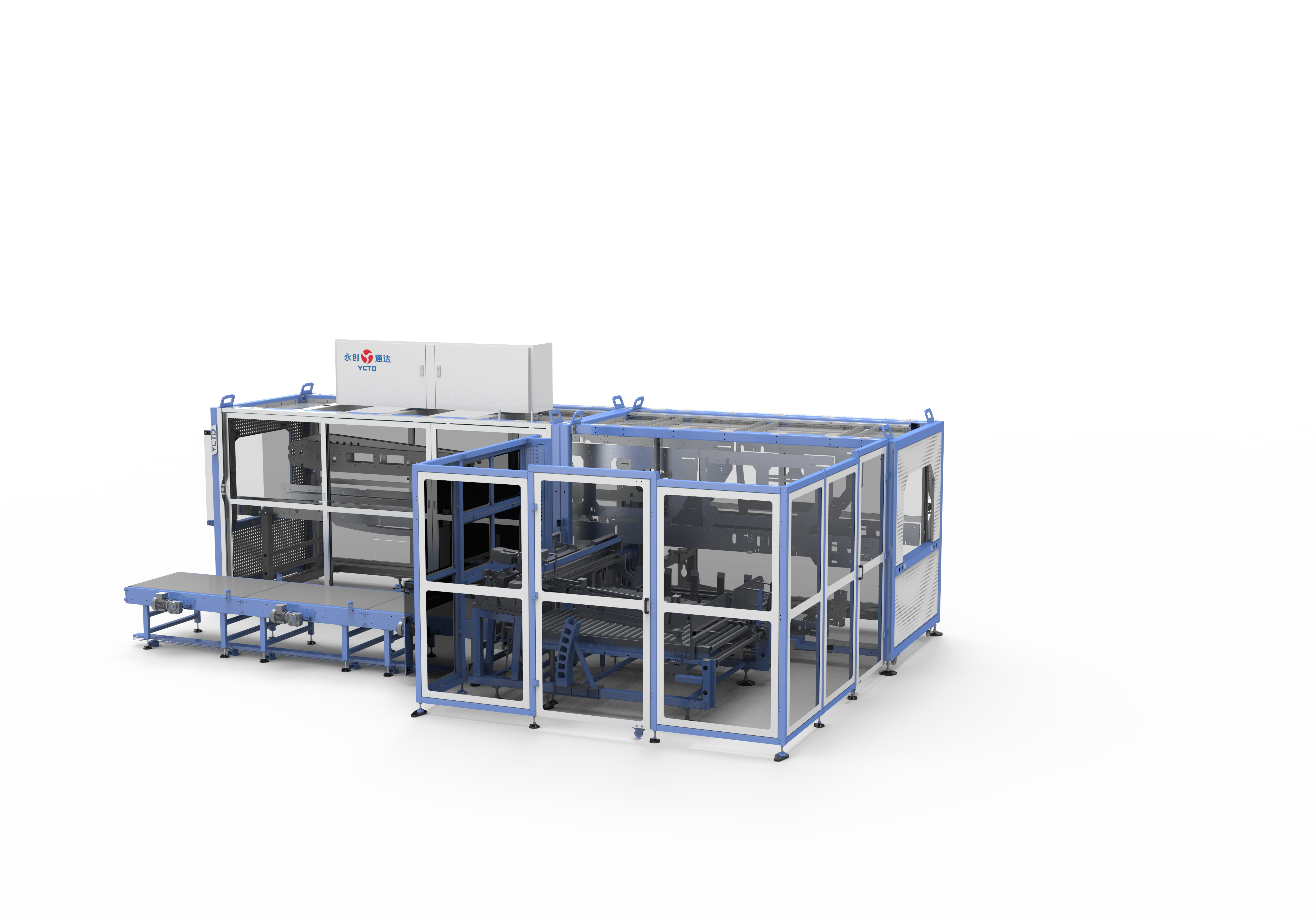

cartonator packing machine

The cartonator packing machine represents a cutting-edge solution in automated packaging technology, designed to streamline and optimize the packaging process across various industries. This sophisticated system combines precision engineering with advanced automation to efficiently handle, fold, and seal cartons at high speeds. The machine features a robust mechanical framework coupled with state-of-the-art electronic controls, capable of processing multiple carton sizes and styles. At its core, the cartonator utilizes a series of synchronized mechanisms including carton feeding, product loading, and sealing stations. The machine's versatile design accommodates various product types and sizes, making it ideal for industries ranging from food and beverage to pharmaceuticals and consumer goods. Advanced features include automatic carton erection from flat blanks, precise product placement, and secure sealing mechanisms. The system's intelligent controls ensure consistent operation while maintaining high-quality standards throughout the packaging process. With production speeds capable of handling up to 60 cartons per minute, depending on the model and configuration, the cartonator significantly enhances packaging line efficiency. The machine incorporates safety features such as emergency stops, guard doors, and monitoring systems to ensure operator safety and product integrity. Its modular design allows for easy maintenance and quick format changes, minimizing downtime and maximizing productivity.