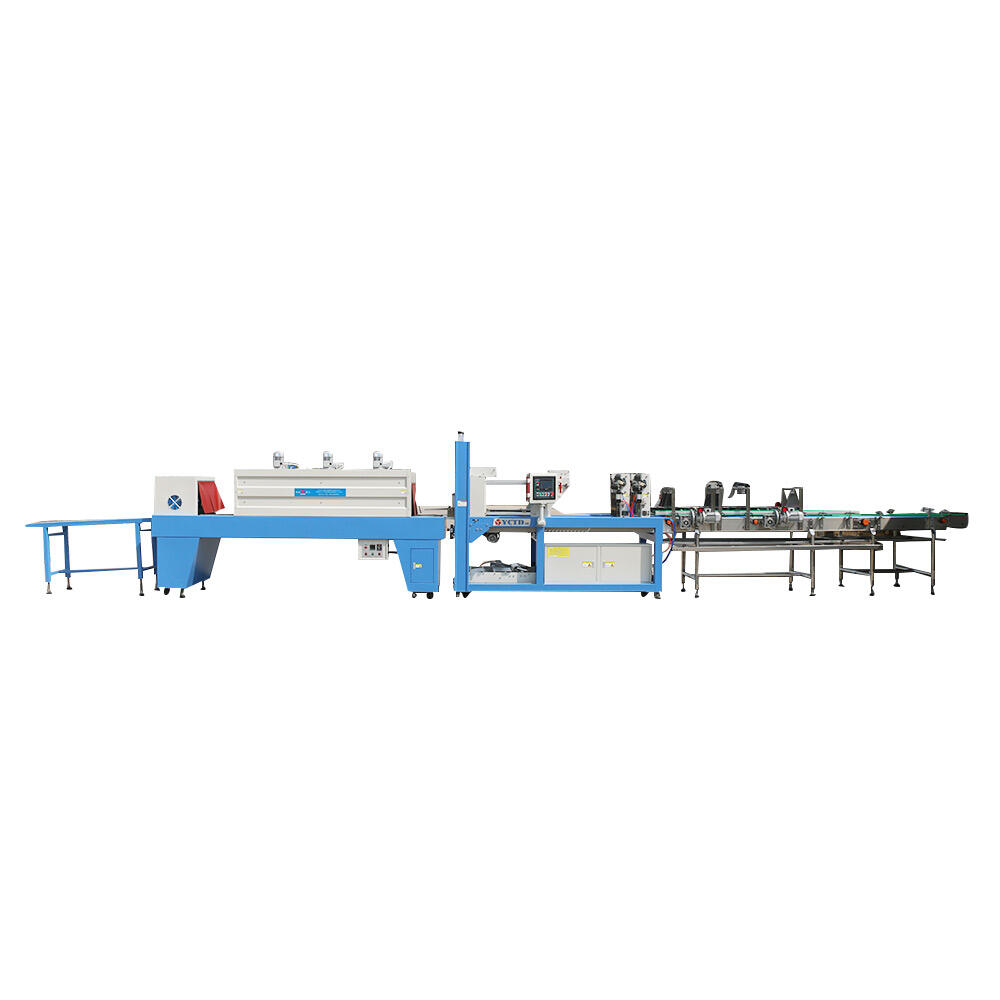

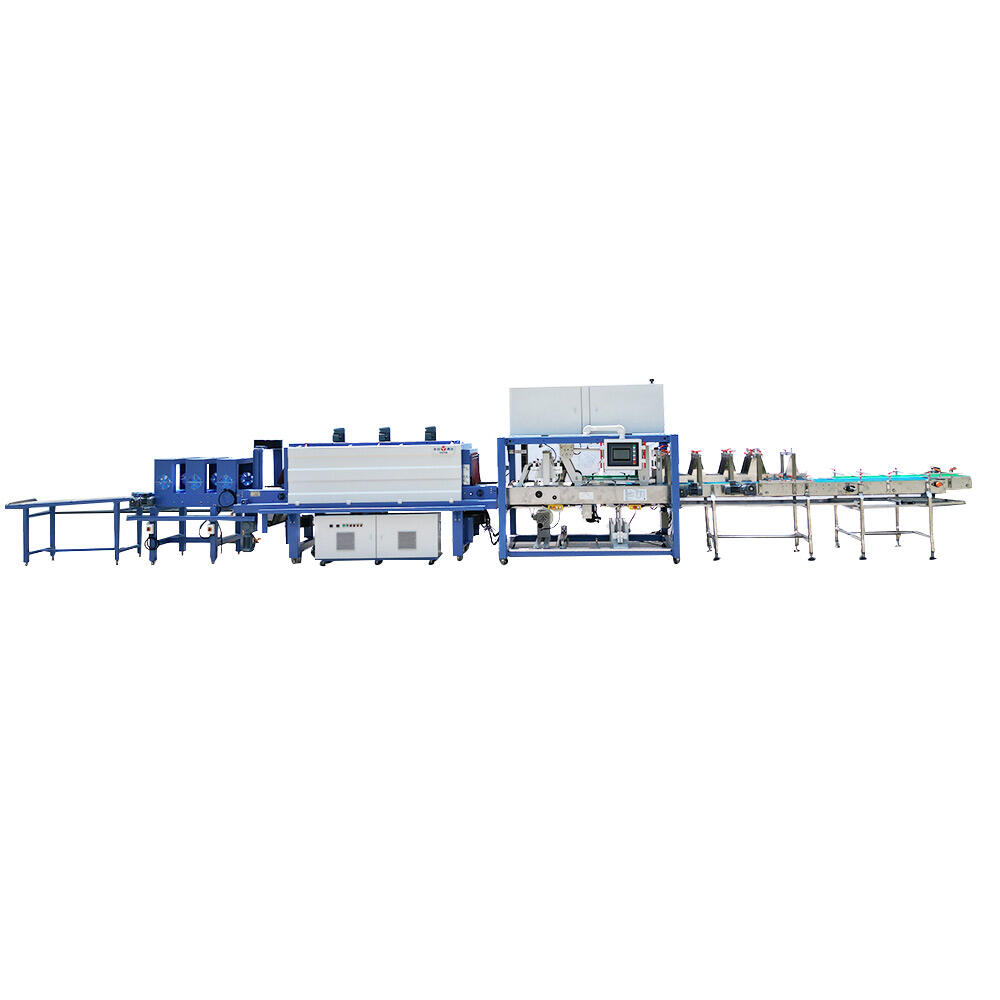

high speed tray packer

The high speed tray packer represents a cutting-edge solution in automated packaging technology, designed to meet the demanding needs of modern production lines. This sophisticated system efficiently organizes and packs products into trays at remarkable speeds, typically handling up to 300 units per minute depending on the model and configuration. The machine incorporates advanced servo-driven technology, ensuring precise product placement and consistent operation throughout extended production runs. Its modular design allows for seamless integration with existing production lines, while the intuitive touch-screen interface enables operators to easily adjust settings and monitor performance metrics in real-time. The system features automatic product collation, tray forming, and precise product placement capabilities, all orchestrated through sophisticated motion control systems. Safety features include emergency stop functions, guard door interlocks, and comprehensive sensor systems that monitor all aspects of operation. The high speed tray packer accommodates various product sizes and tray formats, making it ideal for industries ranging from food and beverage to pharmaceuticals and consumer goods. The machine's stainless steel construction ensures durability and compliance with hygiene standards, while its tool-less changeover design minimizes downtime during product transitions.