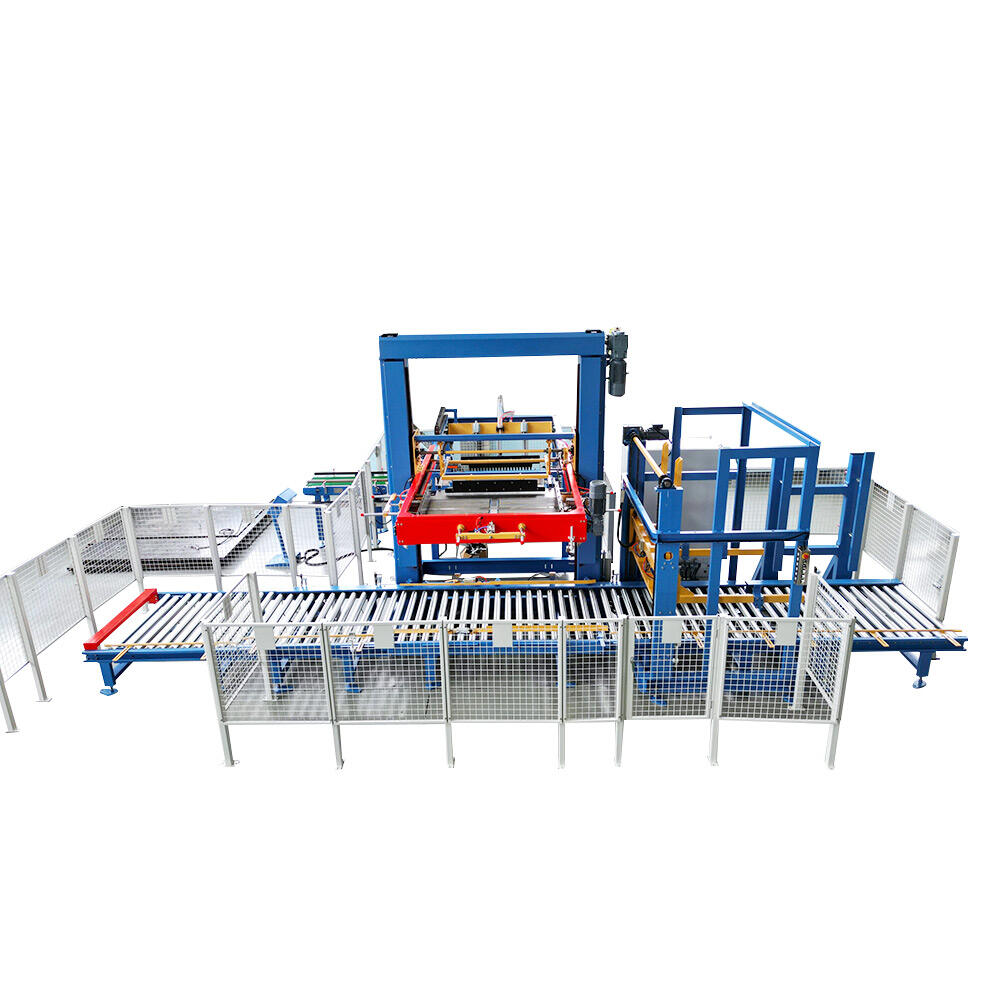

tray packer machine

A tray packer machine is an advanced automated packaging solution designed to efficiently pack products into trays or cases. This versatile equipment streamlines the packaging process by automatically arranging and loading items into pre-formed trays with precision and consistency. The machine incorporates sophisticated servo-driven technology that ensures accurate product placement and gentle handling throughout the packing sequence. Operating at speeds of up to 30 trays per minute, these machines can handle various product sizes and configurations, making them ideal for multiple industries including food and beverage, pharmaceuticals, and consumer goods. The system features an intuitive HMI interface that allows operators to easily adjust settings and monitor performance in real-time. Built with stainless steel construction and modular design, tray packers integrate seamlessly with existing production lines and maintain high sanitation standards. The machine's pick-and-place mechanism utilizes advanced vision systems to detect product orientation and ensure precise placement, while the automated tray forming and sealing capabilities minimize manual intervention. Safety features include emergency stop buttons, guard doors with interlocks, and comprehensive sensor systems that prevent accidents and protect operators.