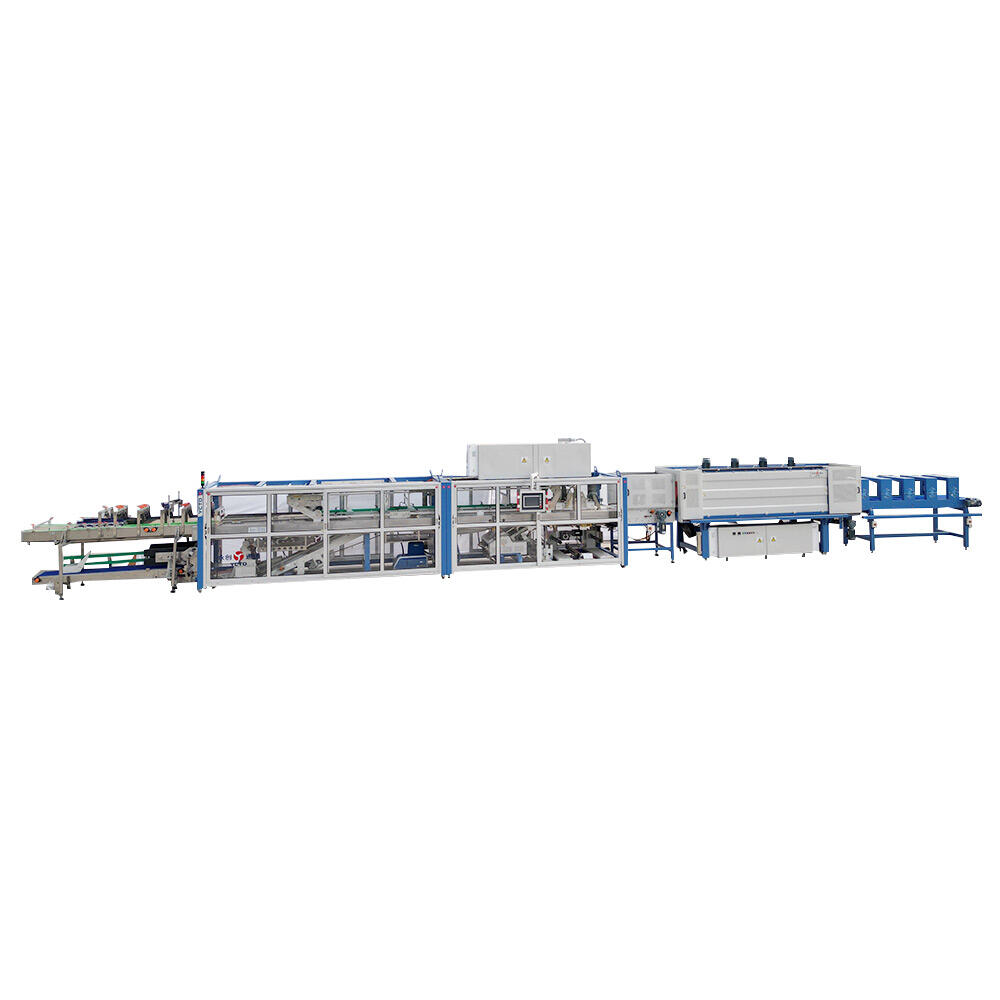

mini pack shrink wrap machine

The mini pack shrink wrap machine represents a compact yet powerful solution for businesses seeking efficient packaging solutions. This versatile equipment combines advanced technology with user-friendly operation, making it ideal for small to medium-sized operations. The machine features a precisely controlled heating system that ensures consistent shrink wrapping results, while its compact footprint makes it perfect for environments where space is at a premium. The system operates through a straightforward process: products are wrapped in shrink film, passed through the heating chamber where hot air circulation causes the film to shrink uniformly around the item, creating a professional, tight seal. With adjustable temperature controls and conveyor speed settings, the machine accommodates various product sizes and film types. Its stainless steel construction ensures durability and easy maintenance, while the energy-efficient design helps reduce operational costs. The mini pack shrink wrap machine is particularly valuable for packaging individual items, bundling multiple products together, or providing tamper-evident sealing for retail goods. Modern safety features include emergency stop buttons and cool-down cycles, protecting both operators and products during the packaging process.