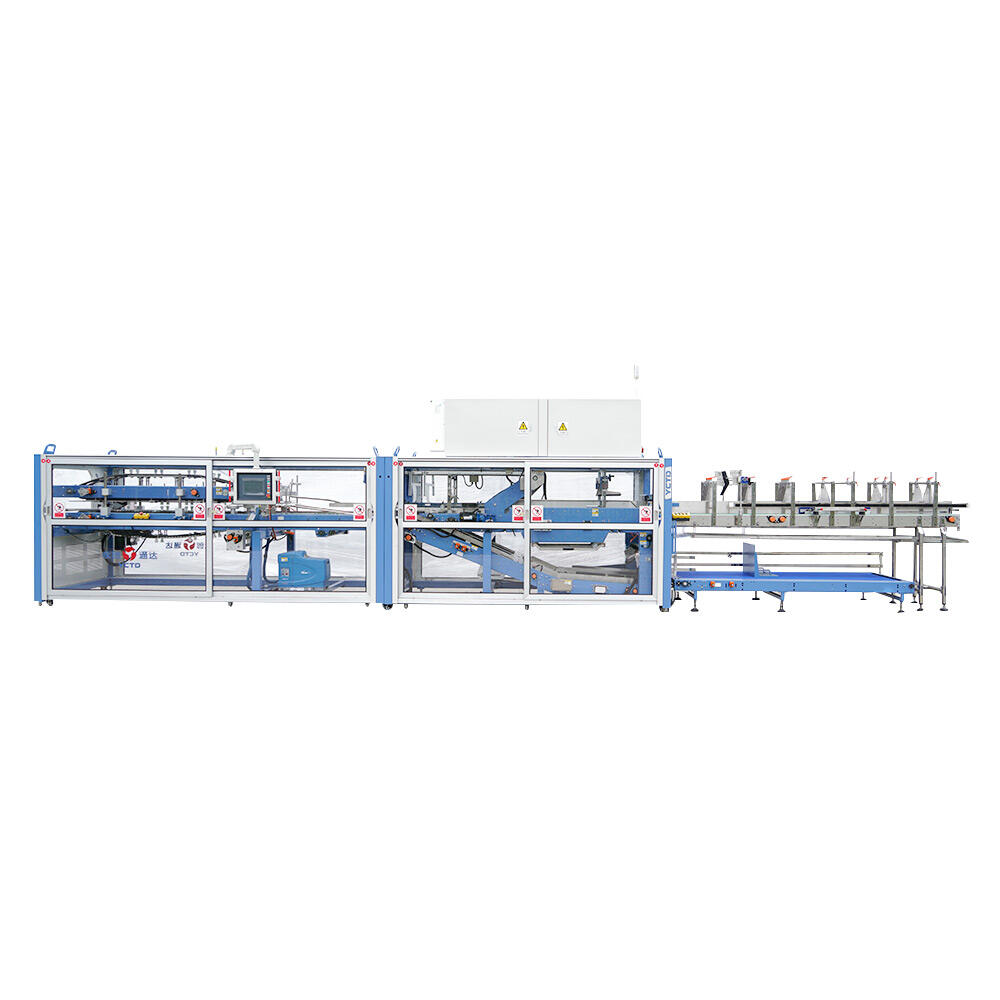

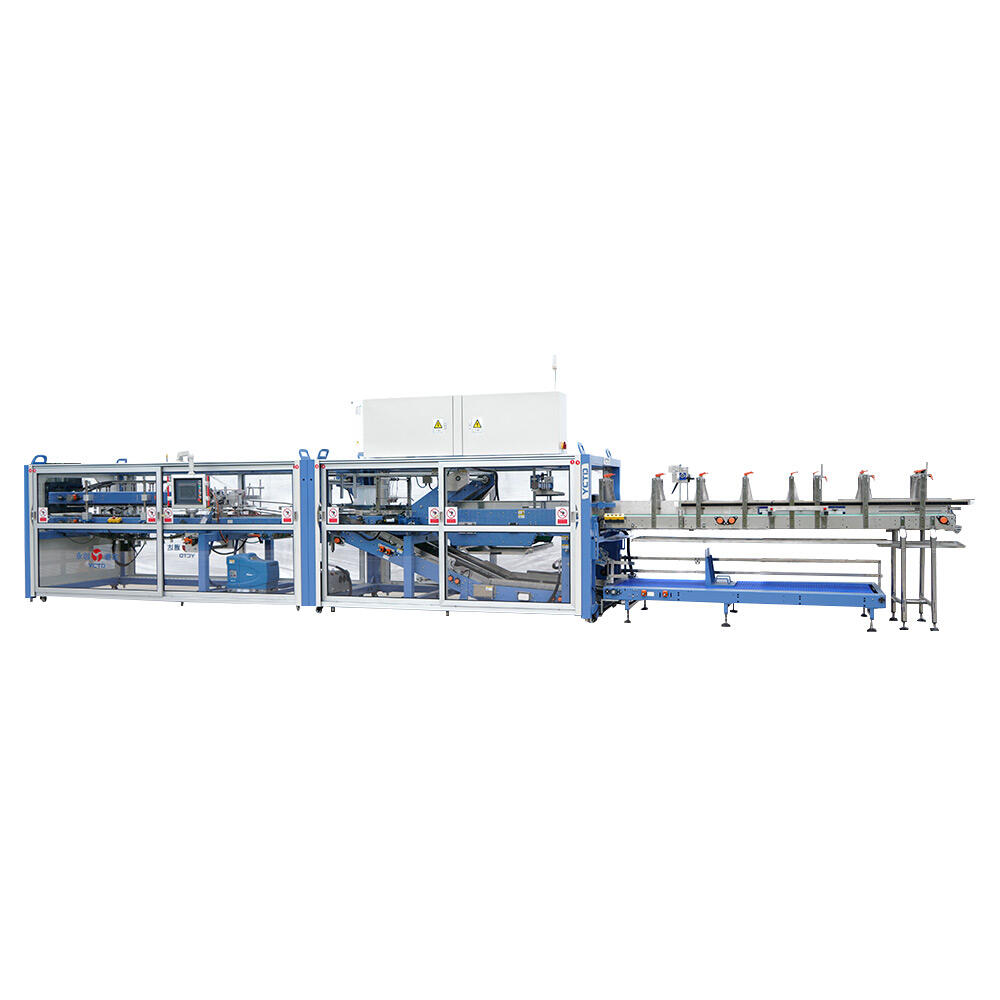

bottle case packer

A bottle case packer represents a crucial automation solution in modern packaging operations, designed to efficiently organize and pack bottles into cases or cartons. This sophisticated machinery seamlessly integrates into production lines, handling various bottle sizes and shapes while maintaining consistent output rates. The system typically comprises multiple components, including conveyor systems, bottle orientation mechanisms, case erecting units, and precise placement systems. Advanced models feature servo-driven technology that ensures accurate bottle handling and placement, minimizing the risk of product damage. The machine's intelligent control system coordinates all movements, from initial bottle separation to final case sealing, maintaining optimal production speeds while ensuring product integrity. Most bottle case packers incorporate flexible programming options, allowing quick changeovers between different bottle sizes and case configurations. The equipment often includes safety features such as emergency stops, guard doors, and monitoring systems that protect both operators and products. Modern bottle case packers can achieve speeds of up to 30 cases per minute, depending on the configuration and product specifications. These machines significantly reduce labor costs while increasing packaging consistency and efficiency across beverage, pharmaceutical, and consumer goods industries.