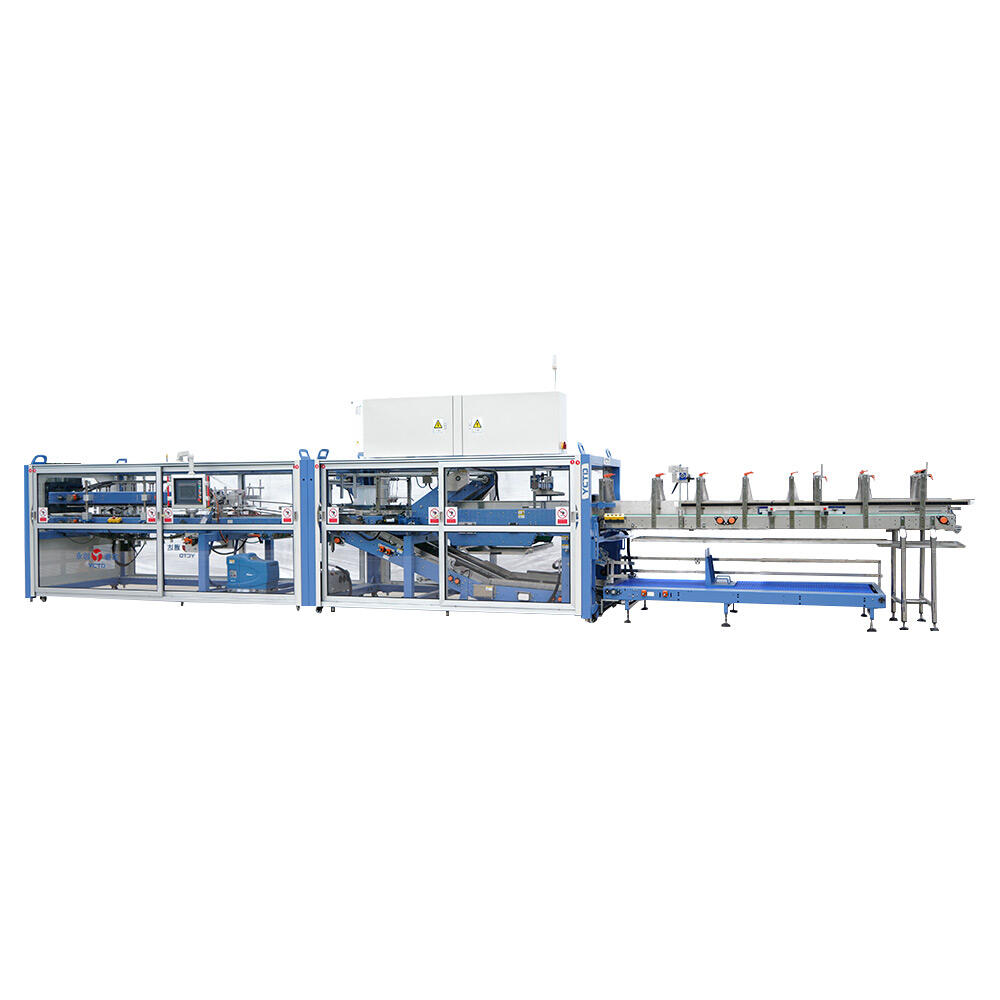

bottle case packer machines

Bottle case packer machines represent a crucial advancement in automated packaging technology, designed to efficiently organize and pack bottles into shipping cases or cartons. These sophisticated systems integrate seamlessly into production lines, handling various bottle sizes and case configurations with precision and reliability. The machines utilize advanced servo motors and PLC controls to ensure accurate bottle placement and consistent operation. They typically feature multiple stations including bottle accumulation, case erection, bottle loading, and case sealing. The technology incorporates sensors and vision systems to monitor bottle orientation and prevent jams, while maintaining high-speed operation of up to 30 cases per minute. These machines can handle different materials including glass, plastic, and metal containers, making them versatile for various industries such as beverage, pharmaceutical, and chemical manufacturing. The system's modular design allows for easy maintenance and quick format changes, minimizing downtime during product changeovers. Advanced safety features include emergency stops, guard doors with interlocks, and clear operation zones to protect operators while maintaining optimal production flow.