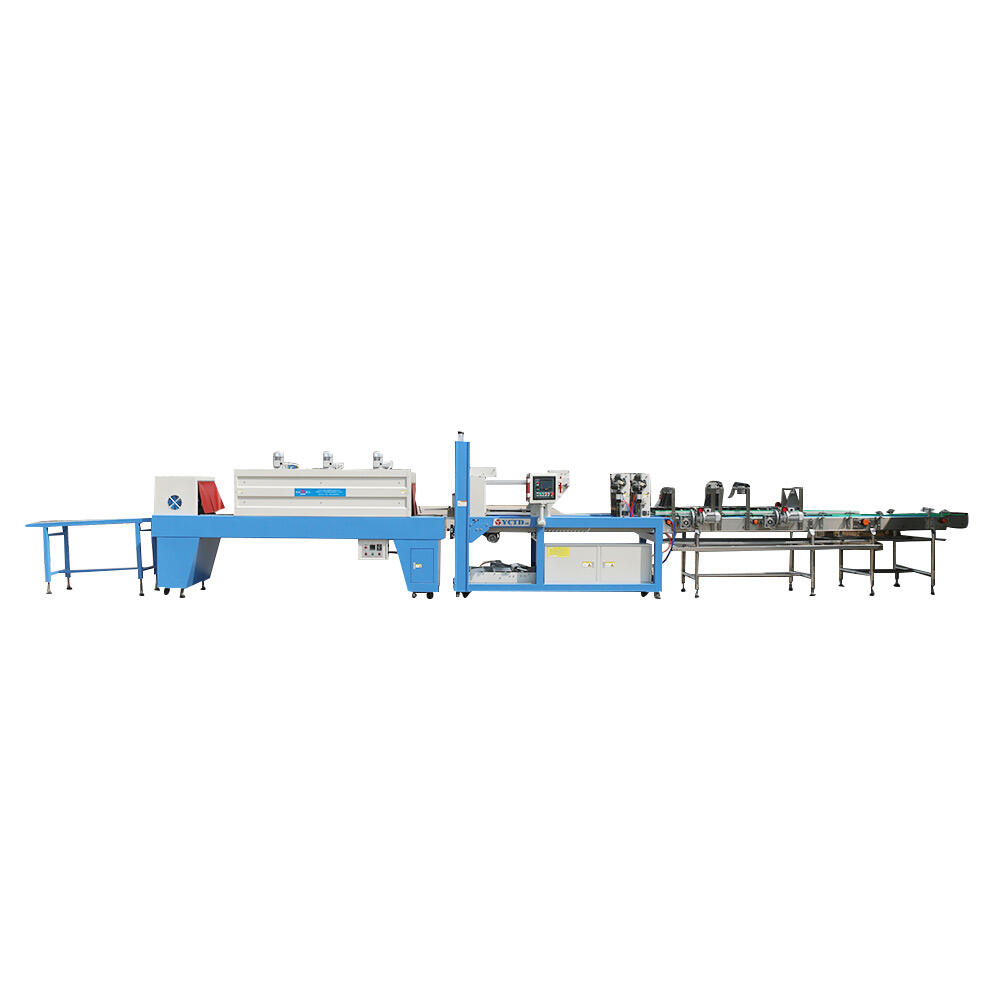

packaging heat shrink wrap

Packaging heat shrink wrap is a versatile and essential material in modern packaging solutions, designed to provide secure and professional-looking product protection. This specialized plastic film contracts when exposed to heat, conforming tightly to the shape of items being wrapped, creating a seamless and protective barrier. The technology behind heat shrink wrap involves a polymer material that's been stretched and cooled during manufacturing, creating a molecular structure that responds to heat by returning to its original, unstretched state. This process results in a tight, custom-fit packaging solution that's both practical and aesthetically pleasing. The applications of heat shrink wrap are extensive, ranging from individual product packaging to bundling multiple items together. It's commonly used in industries such as food and beverage, consumer goods, pharmaceuticals, and retail. The material comes in various thicknesses and compositions, allowing for customization based on specific needs, whether it's for tamper-evident sealing, protection against moisture and dust, or creating stable multi-packs. Modern heat shrink wraps also incorporate advanced features such as UV protection, enhanced clarity for product visibility, and varying degrees of shrink ratios to accommodate different packaging requirements.